Introduction

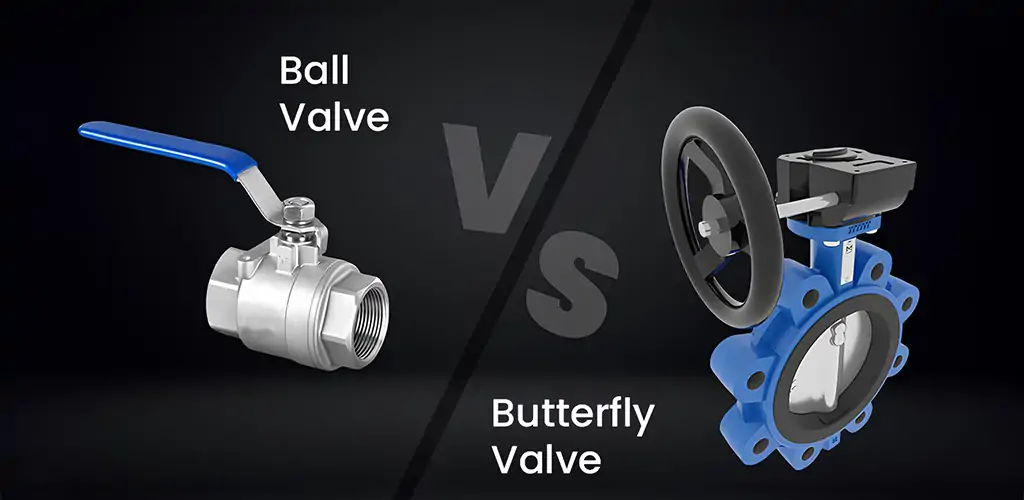

MVS Valve is a leading manufacturer and Exporter of Valves. It play an important role in controlling the flow of fluids, gases, and other media in a variety of industrial applications. Two of the most widely used types of valves are the Ball Valve and the Butterfly Valve. While both serve similar purposes, their design, functionality, and suitability for different applications vary significantly. Selecting the right valve can improve operational efficiency and quality in industries like oil and gas, chemical processing, water treatment, and manufacturing. Understanding the key features, differences, and applications of these valves is important for making informed decisions. In this complete guide, we’ll explore what Ball Valves and Butterfly Valves are, how they work, their unique advantages, and where they are best utilized. Whether you’re new to valve technology or looking for in-depth information, this article provides all the insights you need.

What is a Ball Valve?

A Ball Valve is a quarter-turn valve that uses a spherical disc, or “ball,” to control the flow of fluid or gas. The ball has a hole, known as a port, that aligns with the flow when the valve is open and blocks it when the valve is closed. This straightforward mechanism makes Ball Valves highly efficient and reliable for full shut-off and flow control applications.

Ball Valves are known for their tight sealing capabilities, which minimize leakage even under high pressure. Their design allows for quick operation, as a simple 90-degree turn of the handle transitions the valve between open and closed states. Made from materials like stainless steel, brass, or PVC, Ball Valves are corrosion-resistant and suitable for a range of environments. Commonly used in the oil and gas industry, plumbing, and chemical processing, Ball Valves are favored for their durability, capability, and ease of maintenance.

What is a Butterfly Valve?

A Butterfly Valve is another type of quarter-turn valve that uses a flat, circular disc mounted on a rotating shaft to control the flow. Unlike the spherical disc in a Ball Valve, the Butterfly Valve’s disc resembles a wing or blade, hence its name. The disc rotates within the pipe to either allow flow or block it.

One of the great features of Butterfly Valves is their compact and lightweight design. They require less material and space compared to other valve types, making them an economical choice for larger pipelines. Butterfly Valves are capable, with applications in water distribution, HVAC systems, and industries requiring moderate sealing performance. While they may not offer the same tight seal as Ball Valves, their low-pressure drop and ease of operation make them an excellent choice for specific applications.

Applications of Ball Valves

Ball Valves are commonly used in applications requiring precise control and high-pressure handling. Their capability allows them to be employed across a variety of industries:

- Oil and Gas: Used for controlling crude oil and natural gas flow in pipelines.

- Chemical Processing: Ideal for handling corrosive chemicals due to their durable materials.

- Water Supply Systems: Widely used in municipal water distribution for their tight shut-off capabilities.

- Manufacturing: Used in processes requiring accurate flow regulation of liquids and gases.

Applications of Butterfly Valves

Butterfly Valves are suitable for applications where space-saving and lightweight solutions are required. Their primary uses include:

- Water Treatment: Found in filtration and sewage treatment plants for flow control.

- HVAC Systems: Used to regulate air flow and temperature in heating and cooling systems.

- Food and Beverage: Preferred for sanitary conditions, particularly in beverage production lines.

- Fire Protection Systems: Common in sprinkler systems due to their quick operation and compact design.

Conclusion

Ball Valves and Butterfly Valves play essential roles in industrial and commercial settings. Understanding their differences and applications allows industries to optimize operations and achieve efficient flow control. The choice between these valves depends on factors such as operating conditions, material compatibility, and budget. By selecting the right valve, industries can improve system quality and reduce operational costs.

For more information about Ball Valves and Butterfly Valves, please contact MVS Valve at +91 9998920298 or email us at mayurvalves@gmail.com. Explore our wide range of high-quality products and find the perfect solution for your industry.