Since its establishment in 1978, MVS Valves is one of India’s leading manufacturers of high-quality industrial valves. Over the past 4 decades, the company has consistently demonstrated its expertise and commitment to quality, specializing in steel valves, PTFE lined valves, and thermoplastic valves. With a complete product range, including diaphragm valves, ball valves, gate valves, globe valves, plug valves, butterfly valves, check valves, and strainers, MVS Valves serves a broad array of industries such as petroleum, chemical, metallurgical, and power generation. Their valves, available in materials like cast steel, stainless steel, and duplex steel, can be operated manually or through automated systems such as worm gears, pneumatic actuators, or electric actuators. The company’s commitment to excellence and its focus on using the latest technologies have solidified its reputation as a leader in the valve manufacturing industry.

Commitment to Quality

MVS Valves‘ commitment to delivering high-quality products is reflected in its ISO 9001:2015 certification. This certification is a testament to the company’s rigorous quality control process, making sure that every valve produced meets the exact specifications required by its clients. With quality being at the core of its operations, MVS Valves subjects every product to a thorough inspection and multiple quality checks at every stage of the manufacturing process. This approach Provides that the valves are built to perform under the toughest conditions and for extended periods of time. The company adheres to international standards such as API, ASME, ISO, and others, which make sure that its products meet global benchmarks for safety, performance, and durability. Whether it’s a valve for the oil and gas industry or one for chemical processing, MVS Valves manufactures solutions that are trusted to perform in the most challenging environments.

Broad and Capable Product Line

MVS Valves offers an extensive product range designed to cater to the needs of different industries. Their product portfolio includes:

- Diaphragm Valves

Known for their resistance to corrosive liquids and gases, diaphragm valves are widely used in industries like pharmaceuticals, food processing, and chemical manufacturing. MVS Valves produces these valves using materials like stainless steel and PTFE linings to makes sure longevity and performance in even the harshest environments. These valves are especially suitable for applications where cleanliness and corrosion resistance are paramount.

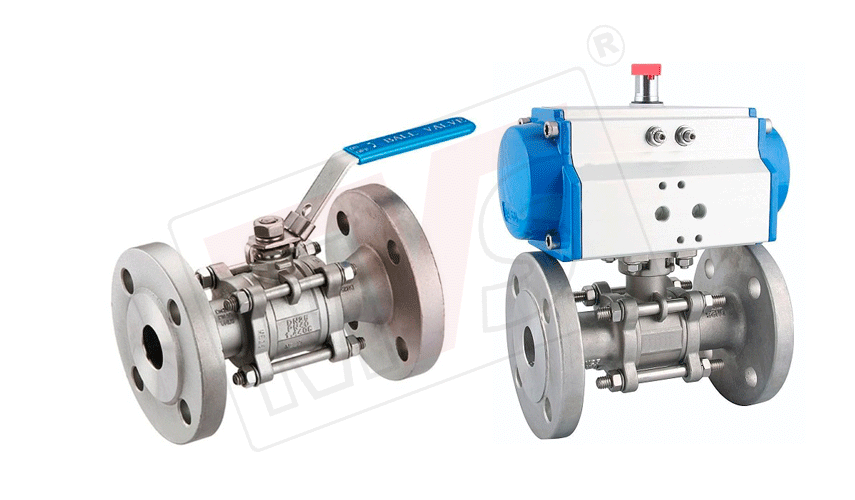

- Ball Valves

Ball valves are designed for tight sealing and flow control, making them ideal for industries such as oil, gas, and water distribution. These valves are commonly used in applications that require quick shutoff. MVS Valves manufactures ball valves using durable materials like cast steel, stainless steel, and duplex steel, providing options that can handle high-pressure environments and various types of fluids or gases.

- Gate Valves

Primarily used in applications where full flow is needed with minimal restriction, gate valves are employed in industries such as water treatment and power generation. MVS Valves designs gate valves to withstand severe operating conditions, providing smooth operation and minimal pressure drop. These valves are designed to handle a wide range of fluids, including water, steam, oil, and gas.

- Globe Valves

In processes where, accurate flow control is essential, globe valves play an important role. These valves are ideal for throttling applications in industries like power plants and steam systems. MVS Valves manufactures high-performance globe valves designed to handle various pressure ratings and temperatures, offering reliable flow control in demanding situations.

- Butterfly Valves

Butterfly valves are known for their lightweight construction and efficient design, making them an excellent choice for industries such as food processing, chemical handling, and water treatment. MVS Valves offers butterfly valves with excellent sealing capabilities, providing efficient operation and requiring minimal maintenance. Their design allows for quick shutoff, making them perfect for applications where fast response is required.

Why Choose MVS Valves?

MVS Valves has earned its reputation as a leader in the valve industry due to several key factors:

- Adherence to International Standards

By adhering to global standards such as API, ASME, and ISO, MVS Valves make sure that its products meet the highest industry benchmarks. This commitment to following internationally recognized quality standards has enabled the company to build a global clientele and serve customers across industries like petroleum, chemical, and power generation.

- Variety of Materials

One of the strengths of MVS Valves is its ability to offer valves in a variety of materials, including cast steel, stainless steel, and duplex steel. The company also specializes in PTFE lined valves, which are particularly useful for handling corrosive substances. This material Capability allows MVS Valves to serve industries with Varies requirements, from chemical plants that require corrosion-resistant materials to the oil and gas sector that demands heavy-duty valves.

- Technology and Innovation

The company’s ability to stay ahead of technological trends is another reason why MVS Valves is a market leader. The use of advanced manufacturing techniques and Innovative machinery enables the company to produce valves that are not only durable but also highly efficient. MVS Valves continually invests in research and development to improve its product line, offering solutions that reduce operational costs and improve system Quality.

- Customization Capabilities

Understanding that different industries have unique requirements, MVS Valves provides customized valve solutions Adjusted to each client’s needs. Whether a client requires a specific valve material, a unique size, or a particular operational method (manual, pneumatic, or electric actuators), MVS Valves offers the flexibility to meet these demands. This capability has made the company a preferred partner for businesses looking for Adjusted solutions to their valve needs.

- Longevity and Durability

Industrial valves often operate in environments where they are exposed to high pressures, extreme temperatures, and corrosive materials. MVS Valves manufactures products designed to withstand these harsh conditions. Their use of materials such as duplex steel and PTFE linings Provides that their valves offer superior durability, minimizing maintenance needs and operational downtime.

MVS Valves in Varies Industries

- Petroleum Industry

In the petroleum sector, where safety and Quality are paramount, MVS Valves plays a critical role. The company supplies ball valves, gate valves, and check valves designed to operate in high-pressure environments such as oil refineries and pipelines. Their products help maintain flow control, prevent leaks, and improve the overall efficiency of petroleum operations.

- Chemical Processing

Chemical plants require valves that can handle corrosive liquids and gases without degrading over time. MVS Valves provides PTFE lined valves and diaphragm valves that are resistant to corrosion, making them ideal for handling chemicals. These valves provide exceptional sealing performance and make sure that harmful substances are contained within the system.

- Metallurgical Industry

The metallurgical industry, where high temperatures and abrasive materials are common, requires valves that can withstand extreme conditions. MVS Valves provides durable solutions like gate valves and globe valves designed to operate reliably in metallurgical processes.

The Role of Innovation and Customer-Centric Solutions

Innovation is a core pillar of MVS Valves’ strategy. The company continually invests in research and development to create products that not only meet current industry needs but also anticipate future demands. By embracing technological advancements and improving the design and functionality of their valves, MVS Valves is able to offer solutions that are more reliable, efficient, and cost-effective. A customer-centric approach has also been key to MVS Valves’ success. The company works closely with its clients to understand their unique challenges and provide Adjusted solutions. Whether it’s developing a valve for a specific application or modifying existing designs to meet special requirements, MVS Valves puts customer needs at the forefront of its operations.

Conclusion

With over 40 years of expertise, MVS Valves has established itself as one of India’s leading valve manufacturers. Their commitment to quality, innovation, and customer satisfaction has enabled them to build long-lasting relationships with clients across Varies industries. Through a wide product range, adherence to international standards, and a focus on Advanced technology, MVS Valves continues to set the benchmark for excellence in the valve manufacturing industry.

Our Range of Products:

For more information about MVS Valves and how we can assist with your valve needs, please call us at +91 9998920298 or mail us at mayurvalves@gmail.com to explore our services and solutions.