PTFE Lined Valve Manufacturer & Exporter

MVS Valves’ PTFE Lined Ball Valve is an advanced flow control solution engineered for handling corrosive, acidic, and hazardous chemical media. Constructed from cast ductile iron with high-performance PTFE lining, this valve is designed for long-lasting service in industries such as chemical processing, pharmaceuticals, petrochemicals, and water treatment. The valve features a full port design, offering unrestricted flow, and a split body two-piece construction that enhances structural integrity and ease of maintenance. Engineered with DIN face-to-face dimensions, the valve includes a replaceable PTFE seat, making sure bubble-tight shutoff under various operating conditions. Available with manual lever operation up to 100 mm and worm gear operation from 150 mm to 300 mm, the valve allows smooth control with low torque operation. Its glandless design ensures safety in high-risk applications, making it a preferred choice for systems requiring corrosion, acid, and chemical resistance. The MVS product range includes a variety of linings such as PFA Lined Ball Valves, FEP Lined Ball Valves, PVDF Lined Ball Valves, and Polypropylene (PP) Lined Ball Valves, each selected based on media compatibility. This fluoropolymer lined ball valves provide unmatched protection against aggressive fluids, while Fluoroplastic Lined Ball Valves and Fluorine Lined Ball Valves ensure operational stability across a wide temperature range. Additionally, the Fluorocarbon Resin Lining Ball Valves are tailored for high-endurance industrial demands.

For special applications, MVS also offers Pneumatic Actuated Fully Lined Ball Valve solutions and Plastic Lined Ball Valves that deliver seamless integration with modern automation systems. The valves are available in large sizes such as DN 200 mm (8") and DN 250 mm (10"), providing scalable options for industrial flow systems. Customers can also choose Stainless Steel SS 304 or SS 316 PTFE, FEP, PFA, PVDF Lined Ball Valves for superior chemical compatibility and longevity.

MVS Valves PTFE Lined Plug Valve is engineered to provide unmatched performance in aggressive and corrosive fluid handling environments. Designed with high-precision casting methods for all pressure-holding components, these valves ensure leak-tight shutoff and long-lasting durability. The valve body, plug, and cover are Carbon Steel (ASTM A216 Gr. WCB), Stainless Steel (ASTM A351 Gr. CF8 / CF8M), or Ductile Iron offered in, making them suitable for a wide range of process conditions. These fully lined plug valves feature virgin PTFE or PFA linings that are securely locked into the metal body, ensuring zero leakage performance in accordance with Class VI shutoff standards. MVS Valves offers PTFE Lined Plug Valve, PFA Lined Plug Valve, and FEP Lined Plug Valve solutions, all designed for high reliability and resistance against chemicals, acids, and high-temperature media. Available in DN 15 to DN 200 (½" to 8"), with ANSI Class 150 / PN 10–16 ratings, these valves comply with API 599, API 6D, and ISO testing standards. Our industrial PTFE lined plug valves are ideal for the chemical industry, chlor-alkali systems, and any fluid handling application where acid resistance and corrosion resistance are essential. Whether it’s fluoropolymer lined plug valves, fluoroplastic lined plug valves, or fluorine lined plug valves, every component is designed for maximum performance in aggressive and corrosive applications. We also offer plug valves with PTFE, FEP, and PFA lining, ensuring full compatibility with varying process fluids. Engineered for bi-directional sealing and featuring a self-lubricating design, the PTFE Lined Cone Valve and Fully Lined Male Valve options are also available for specific use cases. MVS Valves’ product range also includes fluorocarbon resin lined plug valves, plastic lined plug valves, and fluoropolymer lined metal plug valves, all optimized for extended life and high performance under demanding conditions. These reliable and durable lined plug valves are designed to operate with minimal torque and are suitable for high-performance industrial systems.

MVS Valves makes sure that every valve is rigorously tested and built for extended service life, safety, and superior operational efficiency. If your process involves aggressive media, corrosive chemicals, or chlorinated substances, MVS offers the most trusted and high-performance PTFE lined plug valves in the market today.

MVS Valves PTFE Lined Diaphragm Valve is a high-performance solution for industries that demand corrosion resistance, bubble-tight shut-off, and contamination-free operation. Engineered with a Weir A Type cavity-free design, this valve ensures smooth and sterile media flow, making it a preferred choice in chemical, pharmaceutical, and biotech processes. The body lining is available in Polypropylene (PP), PTFE, FEP, PFA, and PVDF, all of which provide outstanding resistance to aggressive chemicals and ensure longer service life. With size ranges from DN 15 to DN 250 and pressure ratings up to PN 16 (ANSI Class 150), these valves are available in ductile iron, carbon steel, and stainless steel construction, with options for manual, pneumatic, and electric actuation. The strong PTFE backed by EPDM or Neoprene rubber diaphragm makes sure tight sealing while resisting both temperature and chemical wear. These lined diaphragm valves are manufactured as per international quality standards and tested rigorously to ensure compliance with operational and safety benchmarks. The PTFE Lined Metal Diaphragm Valves are engineered to handle extreme media in continuous and batch processing systems, ensuring consistent performance over extended cycles. For applications requiring clean, reliable shut-off, Fluoropolymer Lined Diaphragm Valves, including PFA Lined Diaphragm Valves, FEP Lined Diaphragm Valves, and PVDF Lined Diaphragm Valves, deliver excellent thermal and chemical resistance. MVS also offers Fluorine Lined Diaphragm Valves and Fluoroplastic Lined Diaphragm Valves, which are particularly effective in high-purity processes. Whether you require Weir A Type Plastic Lined Diaphragm Valves or Fully Lined Weir A Type Diaphragm Valves, each product is built for reliability, ease of maintenance, and precise control. Our wide range of valves also includes PTFE Lined Weir Type Diaphragm Valves, PFA Lined Weir Type Diaphragm Valves, and PVDF Lined Weir Type Diaphragm Valves, which are suitable for aggressive chemical services, chlor-alkali plants, and acid dosing systems. For larger industrial setups, we manufacture DN 200 (8") and DN 250 (10") Big Size Weir Type PTFE Lined Diaphragm Valves, offering robust operation under high-flow conditions.

MVS makes sure consistent quality across all configurations, including PTFE Diaphragm Valve, Fluorocarbon Resin Lining Diaphragm Valves, and Corrosion Acid Chemical Resistance Lining Diaphragm Valves, delivering long-lasting performance even in extreme conditions. Our valves are trusted in global markets, thanks to our advanced engineering standards and comprehensive range that also includes Stainless Steel SS 304 and SS 316 PTFE, FEP, PFA, PVDF, PP Lined Diaphragm Valves for specialized applications. Every valve reflects our commitment to delivering efficiency, safety, and chemical compatibility—ensuring performance you can trust in the most demanding applications.

MVS Valves PTFE Lined Butterfly Valves are engineered to provide reliable flow control and exceptional corrosion resistance in harsh industrial environments. Designed with a split body construction, these valves feature a fully lined interior using virgin PTFE, FEP, or PFA, making sure maximum protection against highly aggressive and corrosive media. Available in wafer style configurations ranging from 40 mm to 400 mm, MVS offers split body wafer lined butterfly valves with stainless steel or carbon steel discs, making them ideal for use in chemical processing, water treatment, pharmaceutical, and petrochemical applications. The full PTFE lined butterfly valve design makes sure tight shut-off performance and minimal maintenance, even in the most demanding systems. Manufactured as per API 609 and EN standards, and pressure tested to API 598 and EN 12266, these valves deliver smooth, reliable performance with temperature compatibility from –20 °C up to +200 °C, and pressure ratings up to 10 bar. The durable plastic lined butterfly valves provide complete protection from acids, alkalis, solvents, and other corrosive fluids, making them suitable for chemical-resistant and acid-resistant applications. Built for automation and flexibility, MVS PTFE coated butterfly valves are ISO 5211-compatible, allowing integration with pneumatic, electric, or manual actuators for seamless operation. These PTFE lined wafer butterfly valves are widely recognized in the industry for their high quality, low torque, and bubble-tight sealing capabilities. The availability of carbon steel PTFE lined butterfly valves and stainless steel fully lined butterfly valves allows for custom solutions based on process requirements, material compatibility, and industry specifications. With continuous advancements in engineering, MVS provides industrial fully lined butterfly valves that are anti-corrosive, leak-proof, and optimized for chemical compatibility. Whether you need fluoropolymer lined butterfly valves, fluoroplastic lined butterfly valves, or even fluorocarbon resin lined butterfly valves, our extensive range includes fluoropolymer lined metal butterfly valves, ensuring safety and efficiency in fluid handling. For sectors demanding longevity, high performance PTFE lined butterfly valves deliver unmatched resistance to chemical wear and thermal expansion. Every PTFE butterfly valve manufactured at MVS undergoes stringent quality checks, ensuring a robust, reliable heavy-duty lined butterfly valve for long-term performance. Our anti-corrosive butterfly valves are suited for aggressive processing environments and are crafted to exceed customer expectations in both design and durability.

By choosing MVS Valves, you are partnering with a brand known for superior quality in plastic lined wafer butterfly valve systems, tailored to meet the complex needs of modern industries. For any application demanding chemical-resistant, acid-resistant, or corrosion-resistant lined butterfly valves, MVS provides the ideal, engineered solution—backed by years of industry expertise and customer trust.

MVS Valves PTFE Lined Ball Check Valve is designed to deliver long-lasting, corrosion-resistant performance in critical non-return applications. This straight-type, full-port, unidirectional valve features a robust two-piece bolted body construction, fabricated from high-quality cast ductile iron and fully lined with advanced fluoropolymers such as PTFE, PFA, FEP, PVDF, and PP. Built as per ANSI Class 150 and PN 10–16 pressure standards, these valves are available in sizes ranging from DN 15 to DN 150 (½″ to 6″), offering highly reliable service in aggressive fluid systems. The core of this fully lined ball check valve is its encapsulated ball, which ensures tight shut-off and zero backflow. As an industrial lined ball check valve, it is specially developed for chemical, pharmaceutical, ultrapure water, and wastewater applications where leakage, contamination, and corrosion are major concerns. The lined check valve ball type configuration offers a self-cleaning and low-maintenance sealing mechanism, operating silently and efficiently even under fluctuating pressures and fluid compositions. Our ball check valve with PTFE lining is engineered to withstand highly corrosive environments, offering exceptional resistance to acids, alkalis, solvents, and reactive media. Clients can also opt for enhanced durability with ball check valve with PFA lining, ball check valve with FEP lining, PVDF lining, or PP lining, depending on specific fluid compatibility requirements. These linings ensure that every component exposed to the medium is shielded, making the valve ideal for corrosion-resistant applications. MVS offers multiple variants such as FEP lined ball type check valve, PFA lined ball check valve, PVDF lined ball check valve, and polypropylene PP lined ball check valve, each complying with stringent API 598, ASME, and BS EN testing standards. With smooth internal surfaces, minimal pressure drop, and cavity-free construction, these valves guarantee low torque operation and long service life. Whether it's a lined ball type non-return valve for corrosive chemicals or an industrial PTFE lined ball check valve for ultra-clean processes, MVS provides reliable solutions tailored to your needs. These valves are trusted in processing plants, chemical handling systems, and utilities that demand fully lined ball check valves with consistent performance and unmatched safety.

By choosing MVS Valves, you invest in precision-engineered, corrosion-resistant lined ball check valves backed by decades of expertise and manufacturing excellence. Our commitment to quality and innovation ensures that every valve performs with maximum reliability, regardless of the application.

MVS Valves PTFE Lined Wafer Check Valve is a precision-engineered solution designed for maximum reliability in corrosive fluid handling systems. Constructed in a fully lined wafer swing check valve configuration, this valve features a single disc swing type design that fits seamlessly between ANSI B16.5 flanges. Ideal for both vertical and horizontal installations, it offers bubble-tight, bi-directional sealing with PTFE, PFA, or FEP liners to handle highly aggressive or ultra-pure process media. This lined check valve delivers strong non-return protection and zero leakage for applications in acid transfer lines, chemical processing units, pharmaceutical pipelines, and more. The PTFE lined non return valve is engineered for high performance in systems operating between –20 °C and +180 °C, while ensuring minimal pressure drop and silent operation. With its compact wafer-style body, the valve provides space-saving efficiency without compromising flow capacity or chemical resistance. Available in sizes ranging from DN 25 to DN 400 (1″ to 16″), the PTFE lined wafer type swing check valve is compliant with API 594 and EN 12334 standards, offering dependable backflow prevention under fluctuating pressures. MVS also offers variations such as the PFA lined wafer swing check valve, PTFE wafer swing check valve, FEP wafer swing check valve, and fluoropolymer lined wafer swing check valves to suit specific industrial needs. These configurations are ideal for fully lined pipeline systems and are especially effective in environments handling corrosive acids, solvents, or hazardous chemicals. As a trusted PTFE check valve manufacturer and PFA check valve supplier, MVS ensures every valve is rigorously tested for leak-proof performance and structural integrity. From lined wafer swing check valves to full PTFE lined single plate wafer check valves and single door designs, our valves maintain reliable service with no sticking, jamming, or internal cavity accumulation. Designed for corrosion-resistant, acid-resistant, and chemical-resistant performance, our industrial lined wafer swing check valves are built using high-quality materials such as carbon steel and stainless steel, with a durable lining of fluoroplastics, fluoropolymers, or fluorocarbon resins. These valves meet the toughest industrial standards and are built for extended life in demanding fluid environments.

Whether you're specifying a wafer swing check valve with PTFE lining or a wafer check valve with PFA or FEP lining, MVS Valves delivers high-quality components that ensure performance, safety, and long-term value. Each valve in this range supports smooth operation, low maintenance, and is tailored for use in aggressive, corrosive, or sterile systems where failure is not an option.

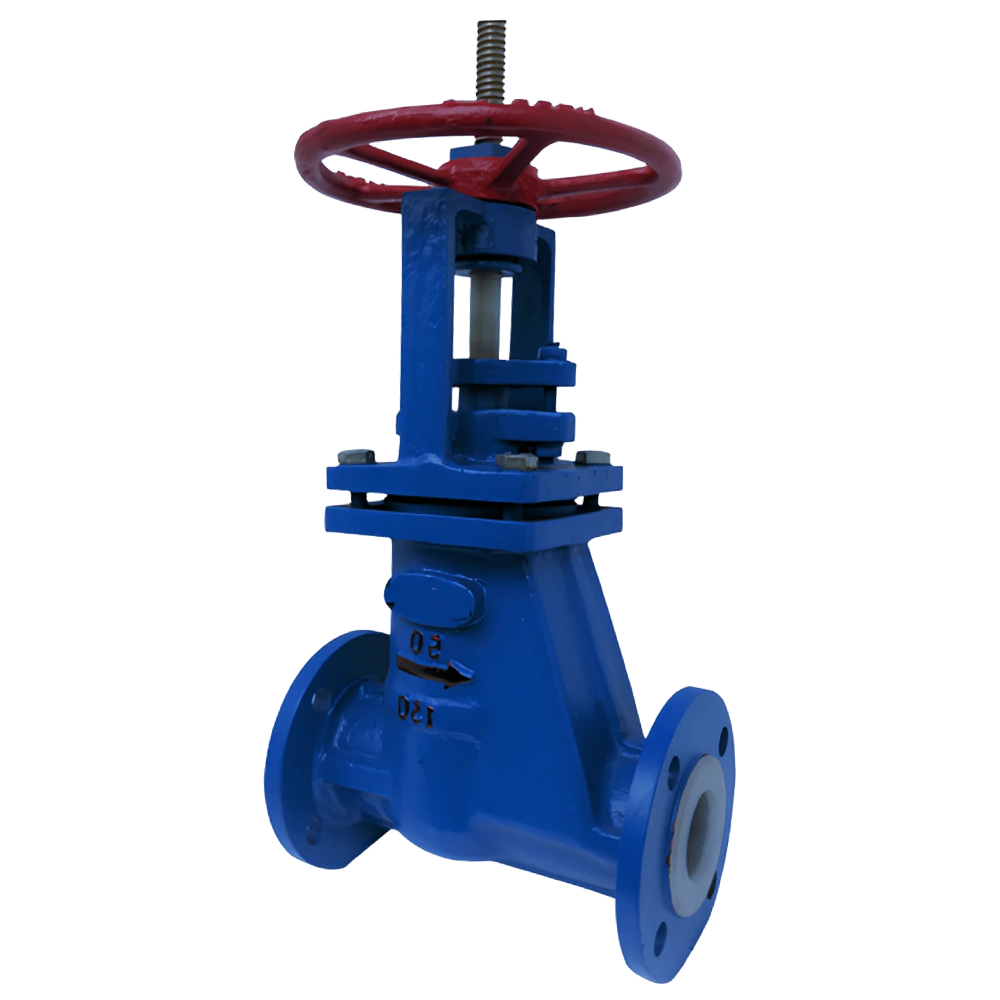

MVS Valves PTFE Lined Gate Valve is specifically engineered to handle highly corrosive, abrasive, and fiber-laden media found in chemical, pharmaceutical, and industrial process systems. Designed to ensure full bore flow and tight shut-off, this valve is available in both rising stem and non-rising stem configurations to suit different installation needs. In the rising stem model, the stem moves vertically along with the disc, allowing clear visual indication of valve position. In contrast, the non-rising stem design operates by rotating the stem without vertical movement, which is ideal for confined spaces. To ensure unmatched corrosion resistance and reliable sealing, MVS offers PFA lined gate valves, FEP lined gate valves, and PTFE lined gate valves with high-integrity linings that withstand aggressive acids, alkalis, and solvents. These linings are permanently bonded to robust cast iron, carbon steel, or stainless steel bodies, delivering long-lasting protection and mechanical stability. The valve’s design ensures smooth operation and prevents clogging, especially when handling particulate-rich or viscous media, which can often lead to jamming in conventional gate valves. Built to comply with global quality standards, our fluoropolymer lined gate valve range provides excellent resistance to a wide range of chemicals and temperatures. These valves are ideal for use in demanding environments like fertilizer plants, chlorine processing units, wastewater treatment, and specialty chemical industries. Each fluoroplastic lined gate valve is tested to ensure zero leakage and reliable operation under fluctuating pressure conditions.

As a trusted OS&Y type lined gate valve manufacturer, MVS focuses on providing valves that not only deliver high performance but also offer operational ease and maintenance-free longevity. Our fluorine lined gate valve models are widely preferred for their superior anti-stick surface, which prevents media buildup and ensures consistent flow. For industries requiring the highest standards of chemical resistance, we also offer fluorocarbon resin lined gate valves that provide exceptional thermal and pressure stability. Whether installed horizontally or vertically, our PTFE lined gate valves maintain full functionality with minimal torque, ensuring hassle-free operation in even the most aggressive process conditions.

MVS Valves PTFE Lined Globe Valve is designed for efficient throttling and shut-off in highly corrosive and chemically aggressive applications. As a linear motion valve, it controls flow by moving a disc directly along the centerline, allowing for precise regulation. Unlike gate valves, globe valves provide faster operation due to shorter disc travel and offer superior control for varying pressure and flow conditions. Built with a rugged cast body and fully lined with PTFE, FEP, or PFA, this valve ensures excellent chemical resistance and long-term reliability. Engineered for demanding industries such as chemical processing, pharmaceuticals, water treatment, and fertilizers, MVS offers PTFE lined globe valves flanged ends Class 150, ensuring compatibility with ANSI piping systems. Our PFA lined globe valve flanged ends Class 150 and FEP lined globe valve flanged ends Class 150 provide exceptional sealing and performance, even in media containing acids, alkalis, and solvents. The internal linings are permanently bonded, protecting the valve body from corrosion while ensuring smooth operation across a wide range of temperatures and pressures. As a trusted manufacturer of fluoropolymer lined globe valves, MVS focuses on safety, precision, and durability. Whether handling reactive chemicals or high-purity fluids, our fluoroplastic lined globe valves maintain their integrity and function without degradation. Industries dealing with aggressive and corrosive media prefer our acid resistant PFA lined globe valves for their non-stick internal surfaces and tight shut-off capabilities. Our chemical resistant lined globe valve options come in robust carbon steel and stainless steel body materials, offering flexibility across various application environments. Whether you need carbon steel lined globe valves for standard operations or stainless steel SS 304 lined globe valves for hygienic and corrosive services, MVS delivers a range of high-performance solutions.

With a compact design, low maintenance needs, and accurate flow control, our plastic lined globe valves are ideal for confined spaces and complex pipeline systems. MVS is committed to offering industrial fully lined globe valves flanged ends that meet international standards and customer-specific requirements, ensuring safety, efficiency, and long service life in every installation.

MVS Valves PTFE Lined Y Strainer is engineered to provide dependable and long-lasting filtration performance in the most demanding chemical and corrosive environments. Designed with a full PTFE/PFA/FEP lining, this Y-type strainer offers excellent protection for downstream equipment by effectively removing solid contaminants from process fluids. The body is constructed from durable materials such as ductile iron, cast steel, or stainless steel, then fully lined with corrosion-resistant fluoropolymers like FEP, PFA, PVDF, or PP. This PTFE Lined Y Type Strainer Filter features a uni-directional bolted cover with a drain plug for easy maintenance and cleaning, ensuring uninterrupted system performance and low-pressure drop. The removable PTFE mesh basket offers high filtration efficiency and extended service life even under continuous exposure to corrosive chemicals. Available in sizes from DN 25 to DN 150 (1″ to 6″) and compatible with ANSI Class 150 / PN 10–16 flanges, it meets ASME B16.34 and API 598 standards for quality and performance. Whether you require a chemical resistant lined Y strainer or a plastic lined Y strainer, MVS offers customized solutions to match diverse industrial requirements. Our PFA Lined Y Strainer is ideal for ultra-pure applications and is trusted by industries like pharmaceuticals, petrochemicals, food processing, and wastewater treatment. We are a leading PTFE Lined Y Strainer Manufacturer and PFA Lined Y Strainer Exporter, delivering consistent quality across global markets.

With reliable PTFE Lined Wye Strainer designs, we support critical systems that handle acids, alkalis, solvents, and high-temperature fluids. As a FEP Lined Y Strainer Supplier, MVS ensures that every product delivers corrosion resistance and operational safety, even in the harshest chemical media. If your application requires a Y type strainer with plastic lining, MVS Valves has the right solution to protect your valuable equipment and maintain optimal flow conditions.

MVS Valves PTFE Lined Sight Flow Indicator is a robust and reliable solution designed for visually monitoring the flow of aggressive and ultra-pure fluids. Built with a fully PTFE/PFA-lined body and durable borosilicate glass viewing windows, this sight flow indicator offers excellent corrosion resistance and high performance under challenging operating conditions. Whether it’s for chemical processing, pharmaceuticals, or ultra-clean fluid applications, this product ensures clear, uninterrupted visibility of media flow. Engineered to meet the rigorous standards of API 598, ASME B16.34, and EN norms, this indicator guarantees quality, safety, and precision. It is available in a double-window type design, with sizes ranging from ½″ to 6″ (DN 15 to DN150) and flanged end connections conforming to ANSI 150 and PN10–16 pressure ratings. The construction materials include Cast Ductile Iron, Cast Steel, and Stainless Steel, all internally lined with PTFE, PFA, or PVDF to handle a wide range of corrosive media.

It can be installed in any pipeline direction, making it a versatile choice for various industrial applications. The industrial PTFE lined sight flow glass is ideal for continuous flow monitoring in systems where product integrity and chemical resistance are essential. From PFA PTFE Lined Sight Flow Indicators to PVDF PTFE Lined Sight Flow Indicators, MVS offers comprehensive variants tailored to specific operational needs. With advanced design and tested durability, our PTFE Lined Sight Flow Indicator stands out as a dependable component for fluid control systems demanding safety, visibility, and long-lasting performance.

The PTFE Lined Basket Strainer Filter is an ideal solution for highly corrosive and aggressive fluid handling systems that demand both effective filtration and superior chemical resistance. Manufactured by MVS Valves with a fully lined internal surface, this strainer combines the mechanical strength of a metal housing with the inertness of PTFE, FEP, or PFA linings, making sure long service life and reliable operation even in the harshest chemical environments. Designed to filter out solid impurities from process streams, this strainer uses a perforated basket-style insert lined with fluoropolymers, which minimizes pressure drop while maintaining flow efficiency. The design also facilitates easy removal and cleaning, ensuring uninterrupted operation and minimal maintenance. The lined flush bottom tank valve integration option allows for efficient drainage and cleaning, especially in vertical installations. In demanding industries where performance cannot be compromised—such as pharmaceuticals, chemical processing, petrochemicals, and wastewater treatment—this anti-corrosive lined flush bottom valve system proves indispensable. We offer variants including the PFA Lined Flush Bottom Valve, FEP Lined Flush Bottom Valve, and specialized Lined Y Type Flush Bottom Valve models, suitable for use in tanks and pipelines requiring bottom discharge solutions.

For actuator-based automation, Pneumatic Lined Y Type Flush Bottom Valves provide efficient control, while stainless steel options such as SS 304 Y Type Lined Flush Bottom Tank Valve and SS 316 Y Type Lined Flush Bottom Tank Valve are also available for enhanced strength and corrosion resistance. Whether you need a PTFE Lined Flush Bottom Valve Manufacturer or a FEP Lined Flush Bottom Valve Exporter, MVS Valves delivers globally trusted solutions designed for durability, safety, and process efficiency in corrosive media applications.

The PTFE Lined Flush Bottom Tank Valve by MVS Valves is specifically engineered for applications that demand safe, efficient, and corrosion-resistant draining of process vessels. Designed to operate in aggressive chemical environments and high-temperature conditions, this valve features a precision-cast steel body that is fully lined with advanced fluoropolymers such as FEP or PFA, offering unmatched chemical resistance and extended service life. Manufactured to meet stringent quality and safety standards, this valve is ideal for bottom discharge in reactors, tanks, and storage vessels. Whether handling acids, solvents, or other corrosive fluids, the fluoropolymer-lined construction ensures zero contamination and high purity in critical fluid systems. The internal design eliminates dead zones and ensures complete drainage without residue, making it suitable for batch processes and CIP/SIP applications. The Flush Bottom Tank Valve is available in both manual and automated versions, supporting integration with pneumatic or electric actuators for remote or process-controlled operations. In industries where reliability and cleanliness are paramount—such as pharmaceuticals, specialty chemicals, and food processing—this valve is a trusted solution. Alongside the flush bottom valve, MVS also offers a range of compatible filtration and flow control accessories, including the PTFE Lined T Type Basket Strainer. This strainer, also available with PFA, FEP, or fluorocarbon resin linings, complements the valve system by providing reliable solid separation. Options such as the Plastic Lined T Type Basket Strainer, Fluoroplastic Lined Basket Strainer, and Fluorine Lined T Type Lined Basket Strainer offer enhanced protection against clogging and equipment wear.

We also manufacture high-performance variants in carbon steel and stainless steel, such as the Carbon Steel MS PTFE Lined Basket Strainer and Stainless Steel PFA Lined Basket Strainer, suited for demanding industrial environments. As a PTFE Lined T Type Basket Strainer Exporter and PFA Lined T Type Basket Strainer Supplier, MVS Valves provides strong, corrosion-resistant solutions tailored to the needs of process industries worldwide.