PVDF Valve Manufacturer & Exporter

MVS Valves PVDF Ball Valve is designed to handle the toughest industrial demands where chemical compatibility and long-lasting performance are non-negotiable. This two-way valve features a robust three-piece full bore construction, offering unrestricted flow and low-pressure drop — ideal for process-critical applications. Constructed using corrosion-resistant materials such as isotactic Polypropylene (PP), PPH, PVDF, and HDPE, it is suitable for handling aggressive chemicals like sulphuric acid, hydrochloric acid, chlorine, bromine, and chlorinated paraffin wax. Available with flanged, screwed, or threaded end connections, the PVDF Ball Valve ensures easy integration into new or existing pipeline systems. The PVDF Ball Valve with flanged ends is widely preferred for fixed installations, while the screwed or threaded end options provide flexibility in compact or modular systems. MVS also offers corrosion resistant plastic manual ball valves and corrosion resistant plastic pneumatic ball valves, giving customers the choice between manual and automated flow control based on their process needs. For automation, the Automatic PVDF Ball Valve with pneumatic actuator delivers efficient and precise control in continuous operation environments. The internal ball, fully encapsulated in PVDF, ensures excellent chemical resistance, making it an ideal solution for chlor alkali industries and for handling Sodium Hypochlorite or Sulphuric Acid with safety and reliability. We are a trusted PPH Body PVDF Lined Ball Valve manufacturer, offering products that combine structural strength with chemical durability. Our Isotactic PP Ball Valve with PVDF ball is widely used in industries where purity and resistance to harsh chemicals are essential, such as pharmaceuticals, food processing, and chemical manufacturing. Whether you're operating in the chlor-alkali sector or managing highly reactive chemical processes, MVS PVDF Ball Valves deliver unmatched reliability, leak-free sealing, and extended service life even in the most corrosive environments.

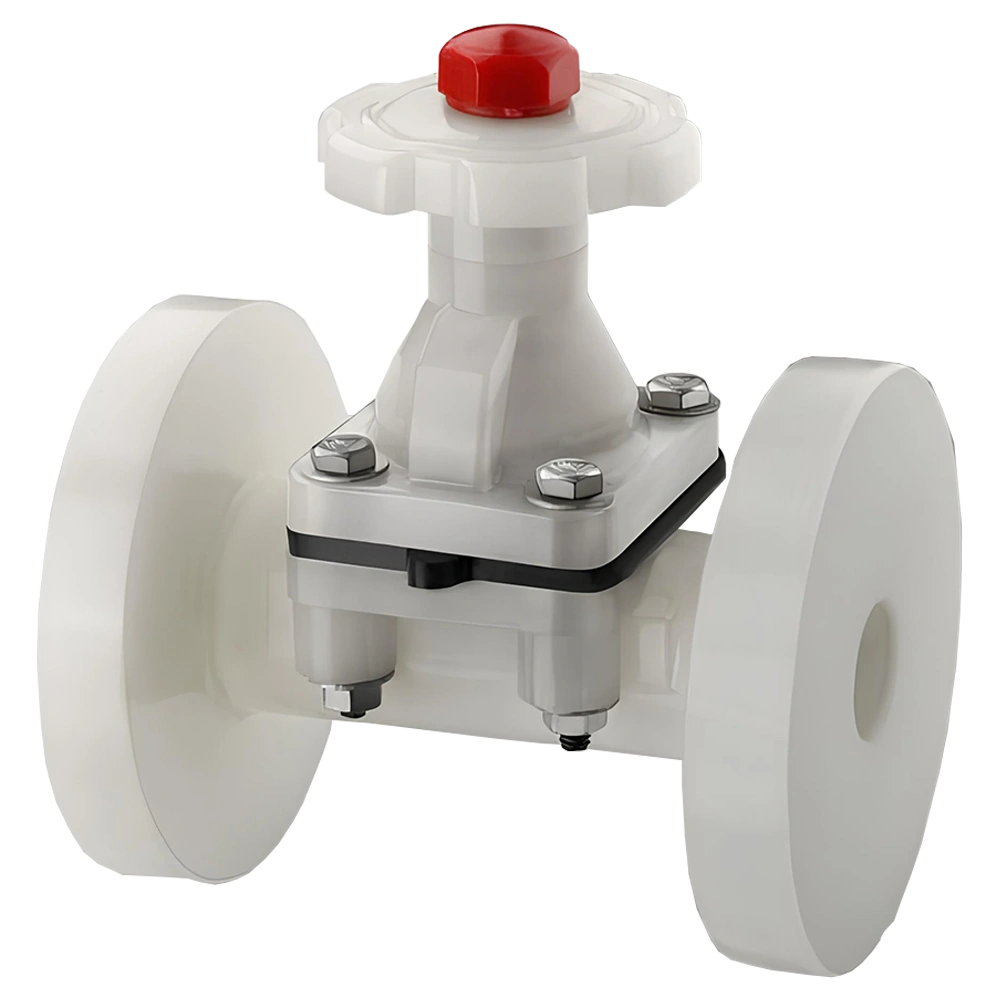

The MVS PVDF Diaphragm Valve is engineered for high-efficiency flow control in highly corrosive and chemically demanding environments. Designed with precision and built using PVDF (Polyvinylidene Fluoride) and Isotactic Polypropylene (PP), this two-way valve offers exceptional corrosion resistance, long-term durability, and smooth performance in both throttling and shut-off applications. Available in sizes ranging from 15 mm to 150 mm, the valve is manufactured to handle diverse industrial media with ease. Its robust thermoplastic body construction is supported by a wide selection of elastomer diaphragm materials, making it adaptable to many operational conditions and process requirements. Whether your application demands a sulphuric acid resistant diaphragm valve or solutions compatible with bromine, hydrochloric acid, or chlorinated fluids, MVS delivers unmatched reliability. Built to serve critical operations, our corrosion resistant PVDF diaphragm valves are ideal for use in chlor alkali processing, bromine handling, and other aggressive chemical applications. For processes involving sulfuric acid, these valves ensure safe and leak-free operation, while resisting wear from abrasion and scaling over time. As a PP diaphragm valve manufacturer and PPH diaphragm valve supplier, MVS brings precision engineering and global supply capability under one trusted brand. Our acid resistant thermoplastic diaphragm valves combine the mechanical strength of polypropylene-based bodies with the chemical shielding of PVDF, creating a valve suitable for a wide variety of harsh environments. MVS also serves as a trusted PVDF diaphragm valves exporter, providing clients worldwide with high-quality, tested, and proven valve systems. Each valve is carefully manufactured to meet international standards for performance, durability, and safety in demanding conditions. From bromine handling plastic diaphragm valves to chlor alkali and sulphuric acid applications, MVS PVDF diaphragm valves offer the performance and reliability your process demands.

The MVS PVDF Ball Check Valve is a precision-engineered, non-return valve designed for use in highly corrosive and chemically aggressive environments. Built in a full bore two-piece construction, this valve operates on a simple yet effective ball-type check mechanism, ensuring unidirectional flow and preventing reverse flow in process pipelines. With options for flanged and screwed end connections, it offers maximum versatility for installation across a wide range of industrial applications. Constructed entirely from thermoplastic materials like Polypropylene (PP), PPH, and PVDF, this valve stands out for its exceptional resistance to corrosion, even when exposed to the most demanding media. The corrosion resistant thermoplastic ball check valve design ensures longevity, low maintenance, and dependable sealing performance, making it ideal for chemical handling industries. MVS is a reputed PPH ball check valve supplier and PVDF ball check valve exporter, serving a broad global clientele in sectors. Our polypropylene ball check valve and PVDF variants are specifically tailored to handle aggressive fluids such as sulphuric acid, nitric acid, and hydrochloric acid with complete safety and minimal wear. Designed for performance in challenging applications, these ball check valves for bromine and chlorine handling are also widely used in systems dealing with sodium hypochlorite, offering enhanced protection through their hydrochloric acid compatible design. Whether your operation involves continuous exposure to corrosive gases or harsh chemical liquids, the MVS PVDF Ball Check Valve offers a robust solution with zero compromise on durability or performance. By integrating chemical resistance, full-flow efficiency, and flexible connectivity, MVS delivers thermoplastic ball type check valves that set the benchmark in industrial non-return valve technology.

The MVS PVDF Foot Valve is an essential component for pump suction lines in aggressive chemical environments, combining the dual functionality of a ball check valve and strainer in a single robust unit. Designed in a two-piece full-flow body construction, this thermoplastic foot valve ensures uninterrupted suction performance while preventing backflow and debris entry, protecting pumps from damage and extending their service life. Constructed using high-performance materials such as PVDF, Polypropylene (PP), PPH, and HDPE, the valve guarantees corrosion resistance even in the harshest media. This corrosion resistant thermoplastic foot valve is engineered with soft-seated, ball-type sealing and optional ceramic/PTFE check balls to enhance chemical compatibility and sealing reliability. Widely used in chlor alkali plants, chemical process systems, and acid handling units, the PVDF foot valve for chemical industries is ideal for suction-side applications involving sulphuric acid, hydrochloric acid (HCL), and nitric acid. With pressure ratings of PN 10–16 (ANSI 150) and temperature resistance from –20 °C to +120 °C, this valve supports global standards such as DIN, ANSI, and JIS.

Recognized as a trusted acid resistant plastic foot valve manufacturer, MVS offers tailored solutions for industrial clients worldwide. As a leading PPH foot valve supplier and chlor alkali foot valve exporter, we ensure long-lasting, maintenance-friendly valves that perform reliably in high-demand operations.

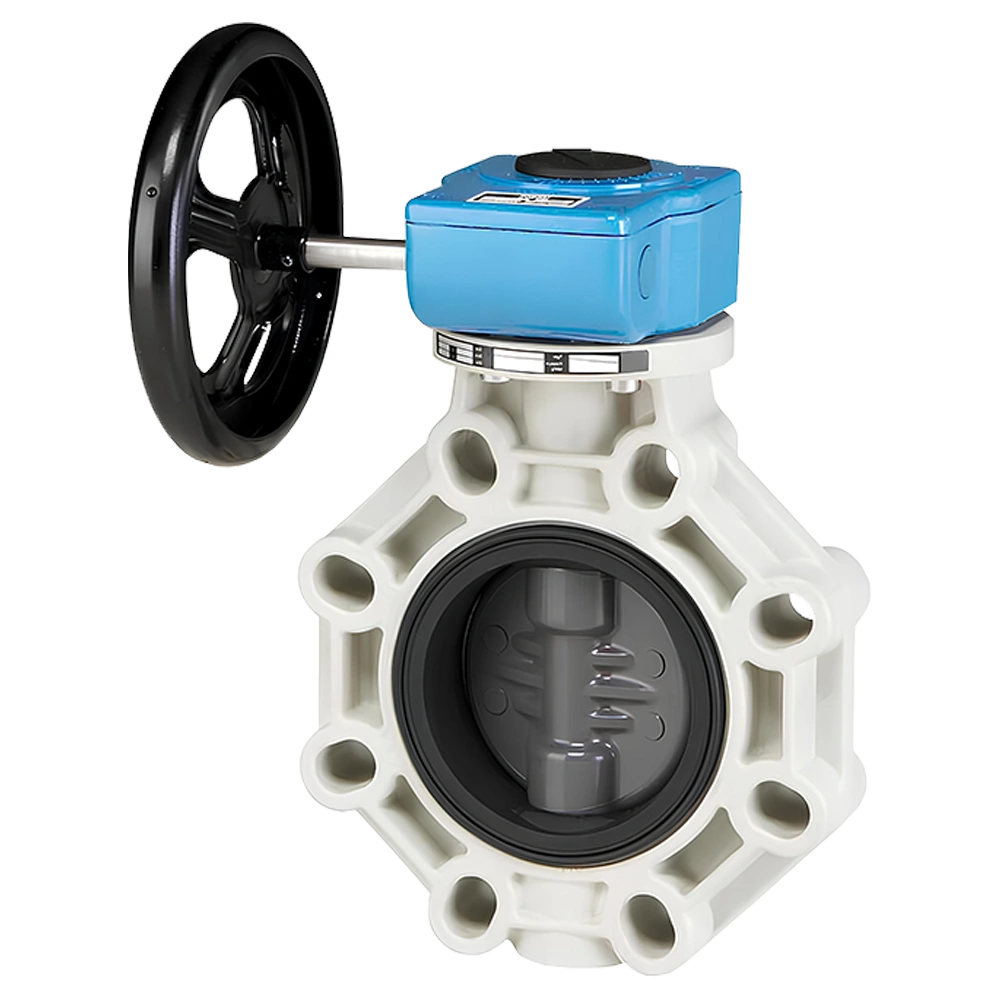

The MVS PVDF Butterfly Valve is engineered for demanding industrial applications that require safe and reliable flow control in highly corrosive and chemical environments. Designed in a compact wafer/sandwich style, this corrosion resistant PVDF butterfly valve fits seamlessly between ANSI B16.5 (150#) flanges, providing efficient sealing and optimal space utilization. With size options ranging from 50 mm to 300 mm, it offers flexible integration into diverse process systems. Manufactured using high-grade PVDF, PP, and PPH materials, the valve delivers exceptional resistance to harsh media such as hydrochloric acid (HCL), nitric acid, sodium hypochlorite, and chlorinated paraffin wax. This makes it a preferred choice across the chemical industry, wastewater treatment facilities, and processing units handling chlorine, acids, and other aggressive fluids. As a trusted PVDF butterfly valve manufacturer and PP butterfly valve supplier, MVS ensures that each valve is precision-engineered for consistent performance, long service life, and low maintenance. The acid resistant thermoplastic butterfly valve body design minimizes pressure drops while the thermoplastic disc and liner provide secure shut-off and enhanced media compatibility. For plants looking to safeguard their systems from chemical wear and fluid contamination, MVS offers advanced solutions like the PPH butterfly valve for chemical industry and the chlorine resistant PVDF butterfly valve. The valve is ideal for installations where durability and chemical resistance are non-negotiable, particularly in acid processing lines, industrial effluent systems, and chemical dosing systems. Whether you need a hydrochloric acid resistant butterfly valve or a sodium hypochlorite butterfly valve supplier, MVS stands as a reliable partner in providing robust, high-performance thermoplastic butterfly valves tailored for harsh and specialized applications.

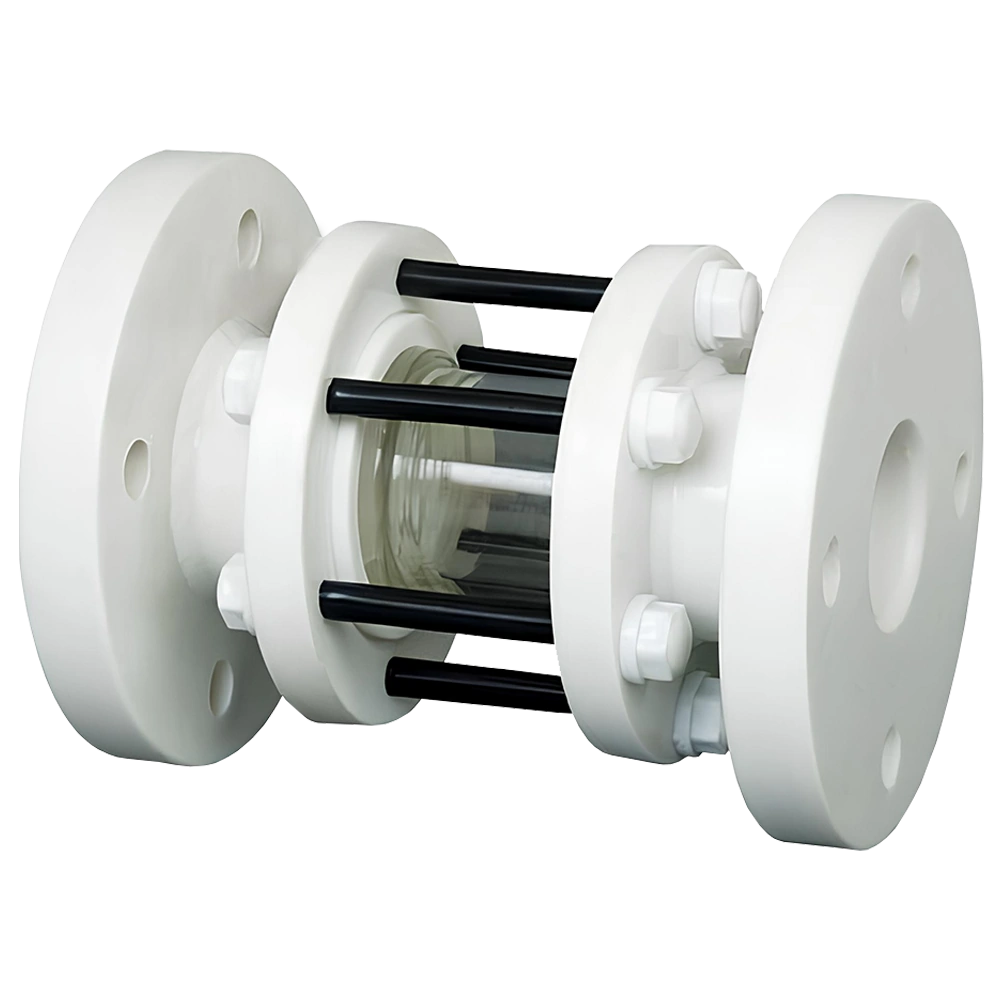

The MVS PVDF Sight Glass is a high-clarity visual inspection solution engineered for aggressive chemical environments. Designed with full PVDF housing and a durable borosilicate glass tube, this unit ensures 360° visibility for safe and continuous monitoring of fluid flow. With a three-piece sturdy construction, it provides a wide viewing area for operators to clearly observe flow conditions in corrosive pipelines, helping to prevent process interruptions or failures. This corrosion resistant thermoplastic sight glass is available in sizes ranging from DN 15 to DN 150 (½″ to 6″) and is compatible with ANSI and DIN flange standards, pressure rated up to PN 16 (~10 bar), and capable of withstanding temperatures between –20 °C and +120 °C. Whether it’s handling water, acids, bases, or ultra-pure chemicals, this chlorine resistant thermoplastic PVDF sight glass offers excellent chemical compatibility and mechanical strength under demanding conditions. The chemical resistant polypropylene sight flow indicator and PPH sight glass supplier options make MVS Sight Glass ideal for viewing media such as sulphuric acid, nitric acid, hydrochloric acid (HCL), and chlorine-based solutions. Its tubular construction ensures low pressure drop and is commonly used in chlor alkali systems, bromine handling lines, and sodium hypochlorite flow indicators.

Engineered for long service life and low maintenance, the PVDF sight flow indicator from MVS is built to meet global safety and quality standards. It enables safe visual control over flow and filling in process lines, ensuring reliable and clear operation even in the most chemically aggressive environments.