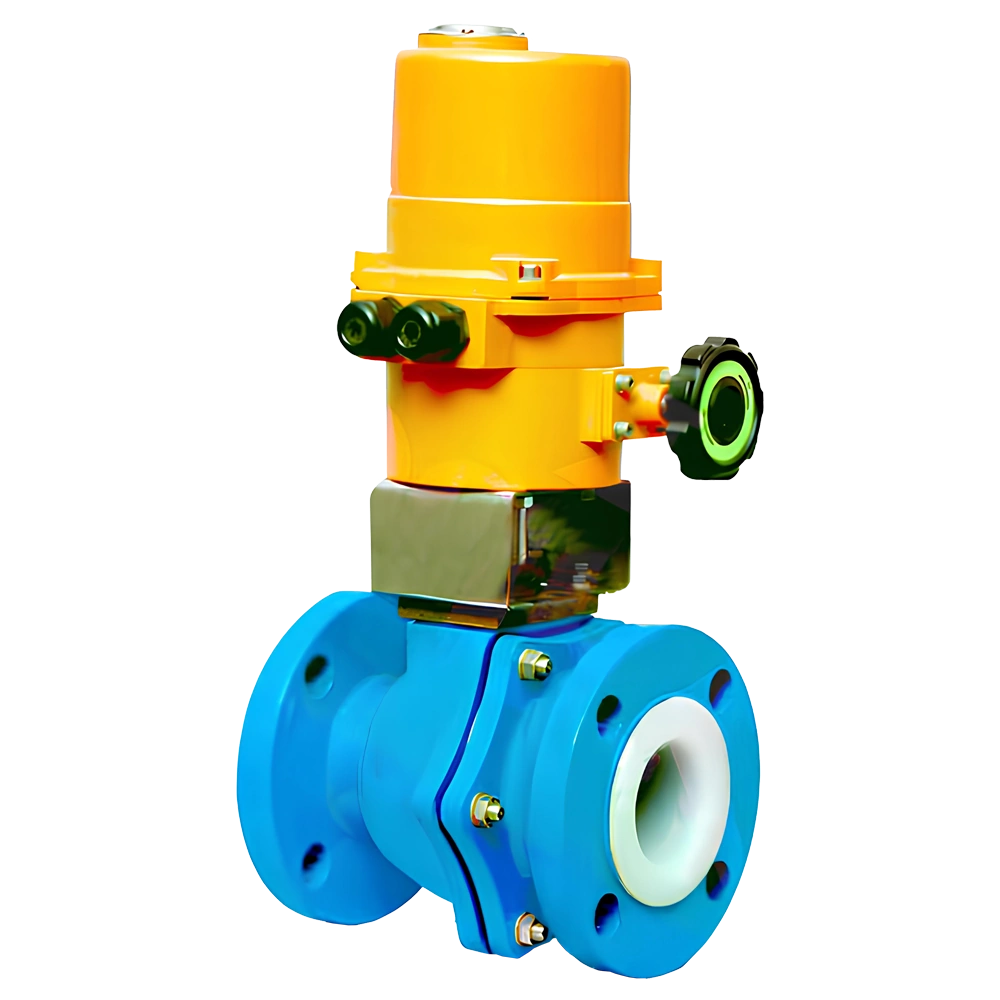

PTFE Lined Ball Valve

PTFE Lined Ball Valve Manufacturer

MVS Valves’ PTFE Lined Ball Valve is an advanced flow control solution engineered for handling corrosive, acidic, and hazardous chemical media. Constructed from cast ductile iron with high-performance PTFE lining, this valve is designed for long-lasting service in industries such as chemical processing, pharmaceuticals, petrochemicals, and water treatment. The valve features a full port design, offering unrestricted flow, and a split body two-piece construction that enhances structural integrity and ease of maintenance.

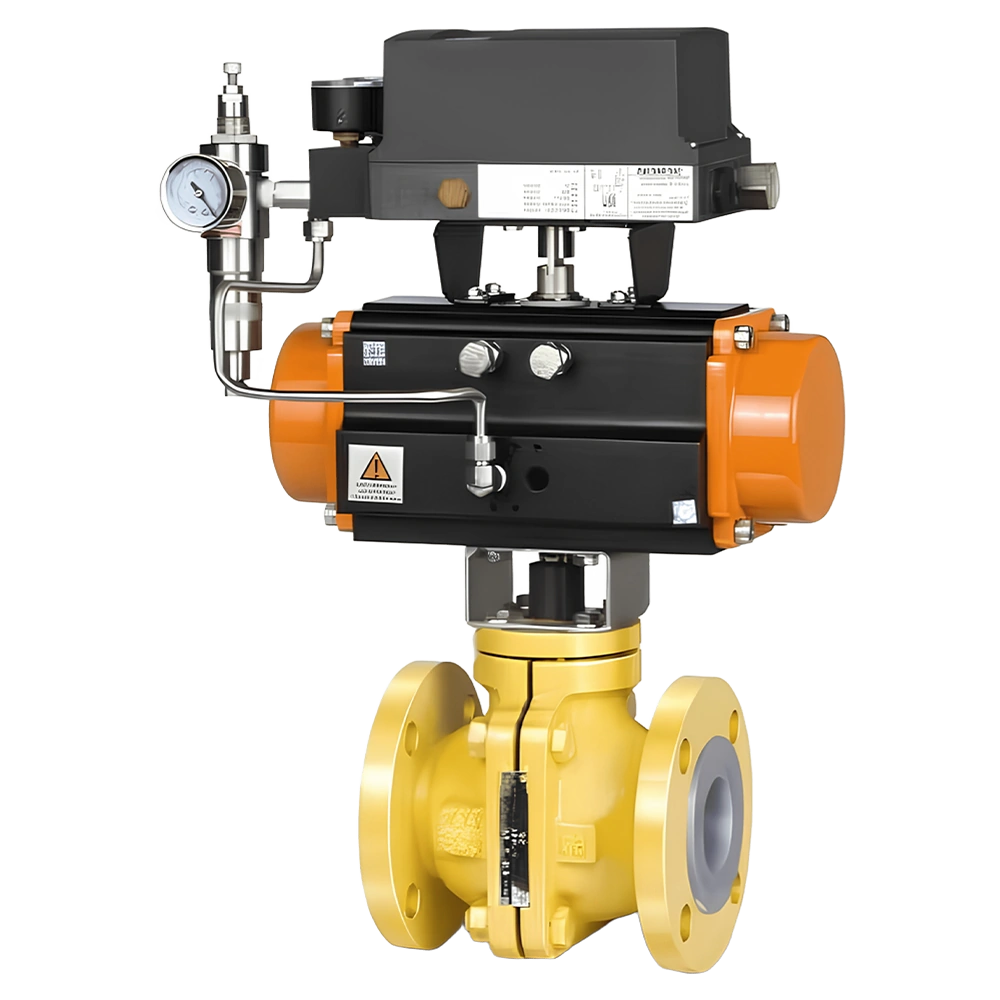

Engineered with DIN face-to-face dimensions, the valve includes a replaceable PTFE seat, making sure bubble-tight shutoff under various operating conditions. Available with manual lever operation up to 100 mm and worm gear operation from 150 mm to 300 mm, the valve allows smooth control with low torque operation. Its glandless design ensures safety in high-risk applications, making it a preferred choice for systems requiring corrosion, acid, and chemical resistance.

The MVS product range includes a variety of linings such as PFA Lined Ball Valves, FEP Lined Ball Valves, PVDF Lined Ball Valves, and Polypropylene (PP) Lined Ball Valves, each selected based on media compatibility. This fluoropolymer lined ball valves provide unmatched protection against aggressive fluids, while Fluoroplastic Lined Ball Valves and Fluorine Lined Ball Valves ensure operational stability across a wide temperature range. Additionally, the Fluorocarbon Resin Lining Ball Valves are tailored for high-endurance industrial demands.

For special applications, MVS also offers Pneumatic Actuated Fully Lined Ball Valve solutions and Plastic Lined Ball Valves that deliver seamless integration with modern automation systems. The valves are available in large sizes such as DN 200 mm (8″) and DN 250 mm (10″), providing scalable options for industrial flow systems. Customers can also choose Stainless Steel SS 304 or SS 316 PTFE, FEP, PFA, PVDF Lined Ball Valves for superior chemical compatibility and longevity.

Specification

| Specification | Details |

|---|---|

| Valve Type | Full Port Lined Ball Valve |

| Valve Size | ½″ to 10″ (DN 15–250) |

| Design Standard | BS EN ISO 17292:2004 (Formerly BS 5351) |

| Flange Drilling | ASA #150 / DIN 2632/2633 / BS 10 Table D, E or F / Customer Specified |

| Face-to-Face Standard | ANSI B16.10 / BS EN 558-1/2 |

| Lining Thickness | 3 to 5 mm |

| Testing Standard | BS EN 12266-1&2 (2003) |

| Hydraulic Test Pressure | Body (Shell) – 20 Kg/cm² Seat – 11 Kg/cm² |

| Pneumatic Test Pressure | Seat – 6 Kg/cm² |

| Spark Test | 15 KVDC |

| Features | Maintenance-free glandless live load design One-piece integral ball stem combination Minimum cavity and full-flow efficiency No backlash in stem and ball after prolonged service Exceptionally low torque compared to plug valve |

| Optional Components | Pneumatic actuator Gear box |

Material of Construction

| Lined Side Piece | Ductile Iron / WCB (FEP Lined) |

| Lined Integral Ball | ASTM A216 Gr. WCB (FEP Lined) |

| Top Cover | ASTM A216 Gr. WCB |

| Lever Boss | ASTM A216 Gr. WCB |

| Lever Rod | MS |

| Seat Ring | PTFE |

| Sphear Bush | PTFE |

| Flexible Diaphragm | PTFE |

| Diaphragm Backup | SS |

| Thrust Washer | MS (Nickel Plated) |

| Disc Spring | Spring Steel (Nickel Plated) |

| Hex Head Bolt | MS |

| Hex Nut | MS |

| Spring Washer | Spring Steel |

| Hex Head Bolt for Top Cover | MS |

| Hex Head Screw for Lever Boss | SS |

| Plain Washer for Lever Boss | SS |

| Grub Screw (Allen Cap) | MS |

| Body Material Options | Ductile Iron GGG40.3 / ASTM A395 Cast Steel ASTM A216 Gr. WCB ASTM A351 Gr. CF8 / SS 304 ASTM A351 Gr. CF8M / SS 316 |

| Lining Material Options | PFA – ASTM D 3307 FEP – ASTM D 2116 PVDF – ASTM D 3222 PP – ASTM D 4101 HDPE |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia