Introduction

The metal and steel industry forms the backbone of global infrastructure, producing materials essential for buildings, transportation, machinery, and tools. This industry operates on highly sophisticated processes that demand precision, efficiency, and safety at every stage. Central to these operations are industrial valves, which make sure the smooth management of liquids, gases, and slurries critical for production. Whether it’s controlling the flow of cooling water, regulating high-pressure gases in smelting furnaces, or isolating hazardous substances, valves are indispensable.

With a varies range of applications, valves help optimize operational efficiency, minimize downtime, and improve safety standards. Selecting the right valve type for specific processes can significantly impact production outcomes and equipment lifespan. This blog explores the critical functions, applications, and types of valves used in the metal and steel industry, as well as the unmatched benefits of sourcing high-quality valves from MVS Valve, a trusted leader in the field.

Understanding the Role of Valves in the Metal & Steel Industry

Industrial valves are pivotal in managing the flow and pressure of fluids and gases across various stages of metal and steel production. From controlling oxygen levels in smelting furnaces to making sure proper water flow during cooling processes, valves maintain operational integrity and product quality.

Key roles of valves include:

- Flow Regulation: Controlling the movement of liquids and gases for optimal processing.

- Pressure Management: Making sure consistent pressure levels to avoid system failures.

- Safety Improvement: Isolating hazardous materials to protect equipment and personnel.

- Energy Efficiency: Reducing wastage by allowing precise control of resources.

Applications of Valves in the Metal & Steel Industry

- Blast Furnace Operations

In blast furnaces, valves control high-pressure gases such as oxygen and nitrogen. Reliable flow control makes sure efficient smelting and reduces energy consumption.

- Steel Rolling Mills

Rolling mills depend on consistent cooling water and lubrication for easy operation. Butterfly valves and ball valves regulate these fluids effectively, maintaining production quality.

- Gas Distribution Systems

Valves like pressure-reducing valves make sure safe transportation and usage of industrial gases such as argon and carbon dioxide, critical for refining and processing.

- Cooling Systems

During steel production, cooling systems prevent overheating. Globe valves and check valves manage water flow rates and prevent backflow.

- Material Handling Systems

Pneumatic conveying systems for transporting raw materials rely on knife gate valves, which can handle abrasive and corrosive substances with minimal wear.

Types of Valves Used in Metal & Steel Production

- Gate Valves

Used primarily for isolation, these valves are excellent for high-temperature and high-pressure systems.

- Butterfly Valves

Lightweight and capable, they are ideal for regulating cooling water and low-pressure fluids.

- Ball Valves

Designed for on-off control, ball valves handle gases and liquids with precision.

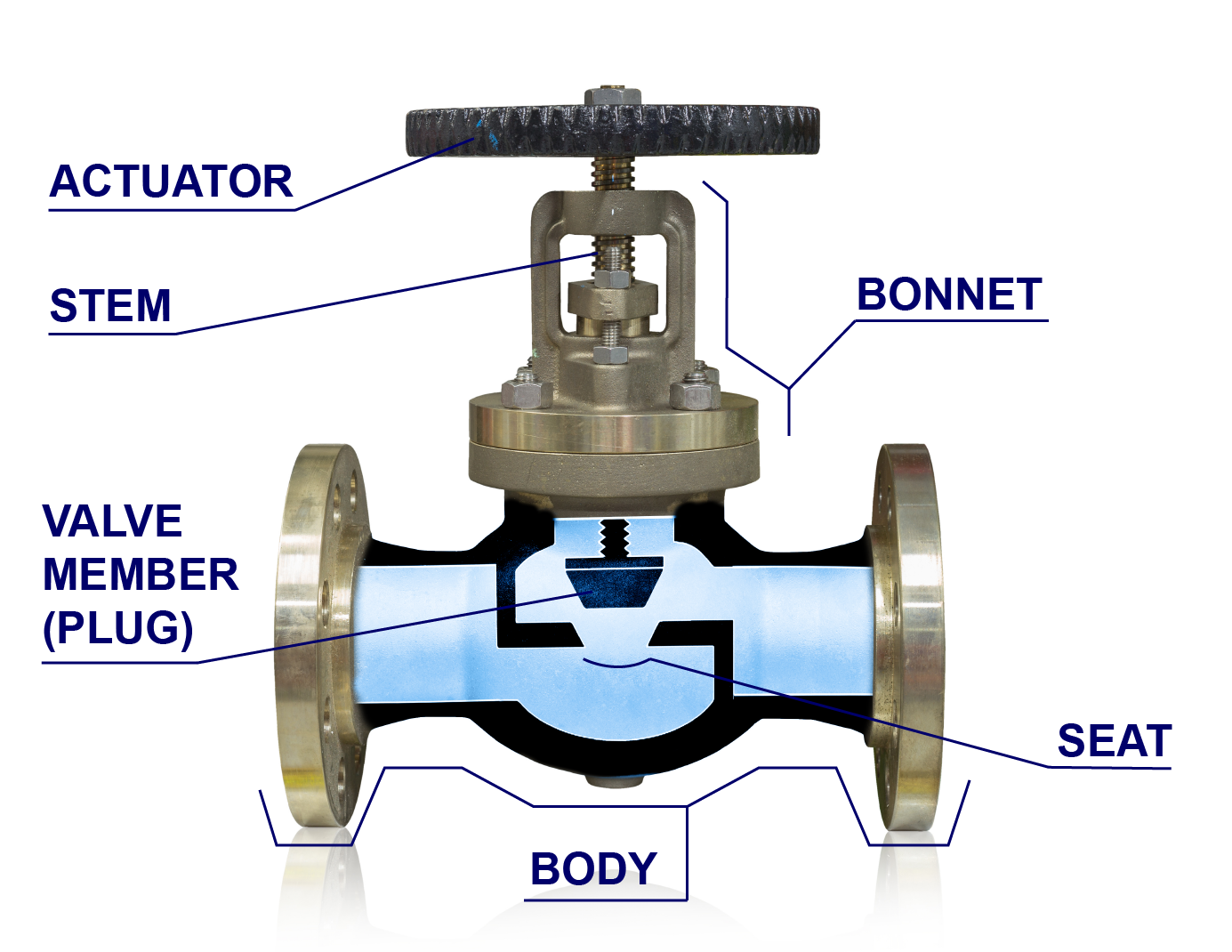

- Globe Valves

Perfect for applications requiring precise flow control, such as steam systems.

- Check Valves

Prevent backflow, making sure the efficiency and safety of cooling systems.

- Knife Gate Valves

Specialized for handling slurries and abrasive media, these valves are strong and reliable.

Why Choose MVS Valve for Industrial Valves?

MVS Valve is a leading manufacturer of high-quality valves adjusted to meet the demanding requirements of the metal and steel industry. Our valves are engineered for durability, efficiency, and safety, making sure optimal performance in even the most challenging conditions.

What Sets MVS Valve Apart?

- Premium Materials: Valves built from stainless steel, ductile iron, and other strong materials.

- Custom Solutions: adjusted designs to meet unique operational needs.

- Precision Engineering: Valves designed for consistent performance and longevity.

- Excellent Support: Complete technical guidance and after-sales service.

Conclusion

The metal and steel industry are a high-stakes sector where precision, safety, and efficiency are paramount. Valves play a critical role in enabling these operations, from controlling the flow of essential resources to making sure the safety of equipment and personnel. Each type of valve, whether it’s a gate valve for isolating sections or a knife gate valve for handling abrasive slurries, contributes uniquely to the production process.

High-quality valves are not just components; they are investments that improved operational efficiency, reduce downtime, and improve overall productivity. Choosing a reliable supplier like MVS Valve make sure that you have access to durable, well-designed valves that meet the exacting demands of the metal and steel industry. By integrating the right valve solutions, companies can streamline processes, achieve cost savings, and maintain high safety standards.

For more information about Valve in Metal & Steel industry, call us at +91 9998920298 or email mayurvalves@gmail.com. Explore our wide range of high-performance valves for all your industrial needs.