MVS Valves is a leading manufacturing and a wide array of industrial valves. With decades of experience and a broad range of products, MVS Valves serves various industries, including the food, beverage, and pharmaceutical sectors, where Performance, hygiene, and Quality are of paramount importance. Industrial valves are important in controlling the flow, pressure, and temperature of fluids like liquids, gases, and steam, all of which are integral in maintaining efficient and safe production systems. In industries like food, beverage, and pharmaceuticals, where contamination and product safety are critical, valves must be meticulously selected to meet specific industry needs. In this, we will explore the role of industrial valves in the food, beverage, and pharmaceutical industries, focusing on the products and expertise of MVS Valves. We’ll also discuss the importance of material selection and how valves contribute to maintaining production quality and efficiency.

Understanding the Importance of Valves in Food, Beverage, and Pharmaceutical Production

Valves play an important role in almost every aspect of production in the food, beverage, and pharmaceutical industries. These valves control the flow of ingredients and processing fluids while maintaining hygiene, safety, and consistency. In such industries, valves are essential for the following reasons:

- Precise Flow Control: In manufacturing processes, controlling the flow rate of fluids and gases is Important to making sure consistency, product quality, and safety.

- Hygiene and Safety: In the food and pharmaceutical industries, hygiene standards are non-negotiable. Valves must meet the highest standards to prevent contamination and make sure the safety of the products.

- Durability and Corrosion Resistance: Valves must withstand harsh environments, chemicals, and pressure variations without degrading in quality. Material selection is critical in these environments.

With its wide range of products, MVS Valves caters to the unique requirements of each of these industries, offering solutions Adjusted to both the technical and regulatory demands.

Types of Valves Used in Food, Beverage, and Pharmaceutical Production

Different industries require different types of valves depending on their specific applications. The most popular valve types used in the manufacturing of food, beverages, and pharmaceuticals are listed down here, along with how MVS Valves helps these sectors.

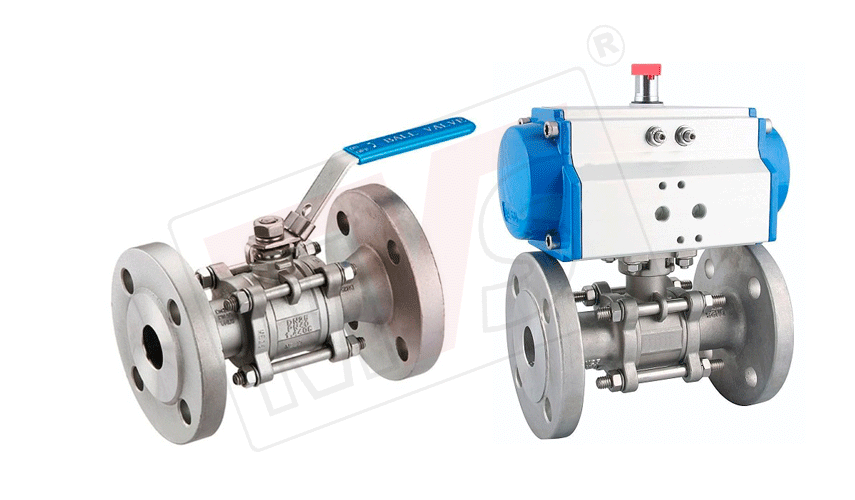

- Ball Valves

Ball valves are among the most common types of valves used in the food and beverage sectors due to their simple design and reliable sealing capabilities. A ball valve consists of a spherical ball with a hole through the middle that controls the flow of liquids or gases.

- MVS Valves manufactures ball valves using high-grade stainless steel, cast steel, and duplex steel, making sure durability and resistance to corrosion. These valves are often used in applications involving beverages, dairy products, and food ingredients.

- Diaphragm Valves

In industries that require aseptic conditions, such as pharmaceutical and beverage production, diaphragm valves are essential. These valves feature a flexible diaphragm that regulates flow by moving up and down to either close or open the valve.

- MVS Valves offers diaphragm valves made from materials like stainless steel and PTFE linings, which provide chemical resistance, hygiene, and durability. These valves are perfect for processes where sterility is important, such as the production of medicines and dairy products.

- Butterfly Valves

Butterfly valves are lightweight, compact, and easy to operate, making them a popular choice in the food and beverage industries, particularly for handling large volumes of liquids like water, juices, and dairy products.

- MVS Valves produces butterfly valves that are highly efficient in applications requiring quick shut-off and throttling capabilities. These valves are made from stainless steel and thermoplastics, providing corrosion resistance and long service life.

- These valves are frequently used in bottling plants, breweries, and dairy processing.

Why MVS Valves is a Trusted Global Leader

MVS Valves has been a leading manufacturer of industrial valves since 1978. Their extensive product range, commitment to quality, and adherence to international standards have made them a trusted name in industries worldwide.

Here’s why MVS Valves is the right choice for your food, beverage, and pharmaceutical valve needs:

- Decades of Expertise: With over 40 years of experience, MVS Valves has a deep understanding of industry requirements, allowing them to manufacture valves that meet the most stringent standards.

- Broad Product Line: From diaphragm valves to ball valves, MVS Valves offers a complete range of products that cater to the specific needs of Varies industries.

- Global Reach: MVS Valves serves customers worldwide, offering reliable solutions that are trusted by businesses in various sectors, including food, beverage, and pharmaceuticals.

- Custom Solutions: MVS Valves offers customized valve solutions Adjusted to the unique requirements of each project, providing flexibility in material choices, valve types, and operational methods.

- Rigorous Quality Control: As an ISO 9001:2015 certified company, MVS Valves adheres to strict quality control standards. Each valve undergoes thorough testing to make sure optimal performance and longevity.

Applications of Valves in Various Industries

Valves are indispensable in industries like food processing, beverage production, and pharmaceutical manufacturing. They are vital for controlling the flow of liquids, gases, and steam throughout production lines, making sure safety, hygiene, and efficiency.

- Food and Beverage Industry Applications

- Ball valves and diaphragm valves are commonly used to control the flow of liquids and gases during food and beverage processing.

- Butterfly valves are ideal for quick shut-off and throttling, especially in liquid-based processes.

- Pharmaceutical Industry Applications

- Globe valves, diaphragm valves, and check valves are essential in making sure precise control of fluids and gases during pharmaceutical production processes.

- These valves contribute to maintaining sterility and preventing contamination.

Conclusion

Valves are an integral part of the production processes in the food, beverage, and pharmaceutical industries. Selecting the right valve for each specific application makes sure the efficiency, safety, and quality of the products being manufactured. MVS Valves, with its decades of experience and a wide range of high-quality products, offers customized valve solutions that meet the demands of these critical industries.

Our Range of Products:

For more information about MVS Valves and how we can assist with your valve needs, please call us at +91 9998920298 or mail us at mayurvalves@gmail.com to explore our services.