PTFE Lined Butterfly Valve

PTFE Lined Butterfly Valve Manufacturer

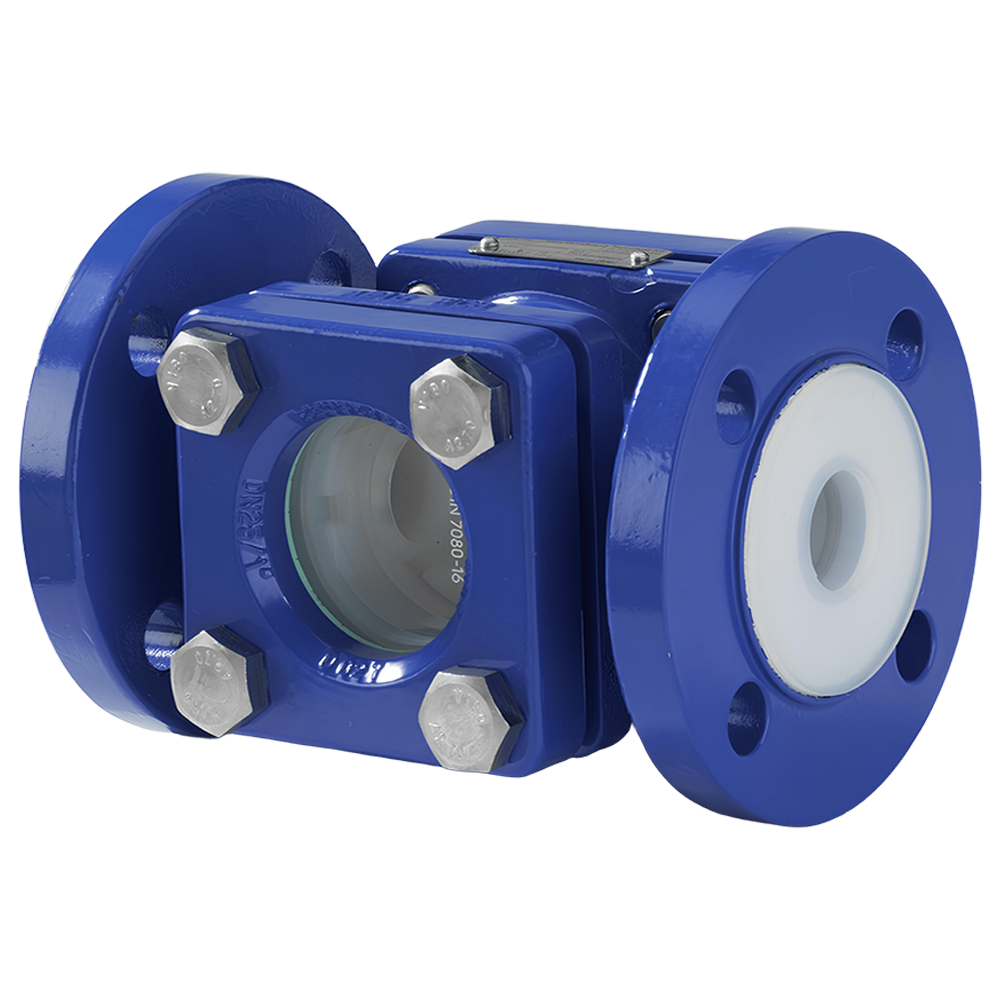

MVS Valves PTFE Lined Butterfly Valves are engineered to provide reliable flow control and exceptional corrosion resistance in harsh industrial environments. Designed with a split body construction, these valves feature a fully lined interior using virgin PTFE, FEP, or PFA, making sure maximum protection against highly aggressive and corrosive media. Available in wafer style configurations ranging from 40 mm to 400 mm, MVS offers split body wafer lined butterfly valves with stainless steel or carbon steel discs, making them ideal for use in chemical processing, water treatment, pharmaceutical, and petrochemical applications.

The full PTFE lined butterfly valve design makes sure tight shut-off performance and minimal maintenance, even in the most demanding systems. Manufactured as per API 609 and EN standards, and pressure tested to API 598 and EN 12266, these valves deliver smooth, reliable performance with temperature compatibility from –20 °C up to +200 °C, and pressure ratings up to 10 bar. The durable plastic lined butterfly valves provide complete protection from acids, alkalis, solvents, and other corrosive fluids, making them suitable for chemical-resistant and acid-resistant applications.

Built for automation and flexibility, MVS PTFE coated butterfly valves are ISO 5211-compatible, allowing integration with pneumatic, electric, or manual actuators for seamless operation. These PTFE lined wafer butterfly valves are widely recognized in the industry for their high quality, low torque, and bubble-tight sealing capabilities. The availability of carbon steel PTFE lined butterfly valves and stainless steel fully lined butterfly valves allows for custom solutions based on process requirements, material compatibility, and industry specifications.

With continuous advancements in engineering, MVS provides industrial fully lined butterfly valves that are anti-corrosive, leak-proof, and optimized for chemical compatibility. Whether you need fluoropolymer lined butterfly valves, fluoroplastic lined butterfly valves, or even fluorocarbon resin lined butterfly valves, our extensive range includes fluoropolymer lined metal butterfly valves, ensuring safety and efficiency in fluid handling. For sectors demanding longevity, high performance PTFE lined butterfly valves deliver unmatched resistance to chemical wear and thermal expansion.

Every PTFE butterfly valve manufactured at MVS undergoes stringent quality checks, ensuring a robust, reliable heavy-duty lined butterfly valve for long-term performance. Our anti-corrosive butterfly valves are suited for aggressive processing environments and are crafted to exceed customer expectations in both design and durability.

By choosing MVS Valves, you are partnering with a brand known for superior quality in plastic lined wafer butterfly valve systems, tailored to meet the complex needs of modern industries. For any application demanding chemical-resistant, acid-resistant, or corrosion-resistant lined butterfly valves, MVS provides the ideal, engineered solution—backed by years of industry expertise and customer trust.

Specification

| Specification | Details |

|---|---|

| Valve Type | Split Body – Wafer Type |

| Design Standard | BS EN 593:2004 (Formerly BS 5155) |

| Valve Size | 2″– 24″ (DN50 – DN600) |

| Drilling | ANSI B16.5 / DIN PN10/16 |

| Face to Face | API 609 / BS 5155 / ISO 5752 / BS EN 558-1/2 |

| Lining Thickness | 3 to 5 mm |

| Testing Standard | BS EN 12266-1&2 (2003) |

| Test & Inspection - Hydraulic | Seat – 11 Kg/Cm² |

| Test & Inspection - Pneumatic | Seat – 6 Kg/Cm² |

| Spark Test | 15 KVDC |

| Features | Maintenance free high performance design Bubble tight closer provides process efficiency Dynamic live loaded seal design for superior operation Intact performance under corrosion, abrasion and temperature fluctuation |

| Optional Components | Gear Box / Actuator Unlined Disc – ASTM A351 Gr. CF8 / CF8M Extended Stem Design Lug Type Design |

Material of Construction

| Wafer Type Body | ASTM A216 Gr. WCB |

| Body Liner | FEP / PFA / PTFE / PVDF |

| Disc With Integral Shaft | CS with SS Shaft (Encapsulated with FEP / PFA / PVDF) |

| Elastomer Backup | Silicon |

| Wedge Ring | PTFE |

| Thrust Washer | SS |

| GFT Bush | Glass Filled PTFE |

| Guide Bush | SS PTFE Coated |

| Lever Assembly | CS |

| Body / Disc Material Options | Ductile Iron GGG40.3 / ASTM A395 Cast Steel ASTM A216 Gr. WCB ASTM A351 Gr. CF8 / SS 304 ASTM A351 Gr. CF8M / SS 316 |

| Lining Material Options | PTFE – ASTM D 4895-91a PFA – ASTM D 3307 FEP – ASTM D 2116 PVDF |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia