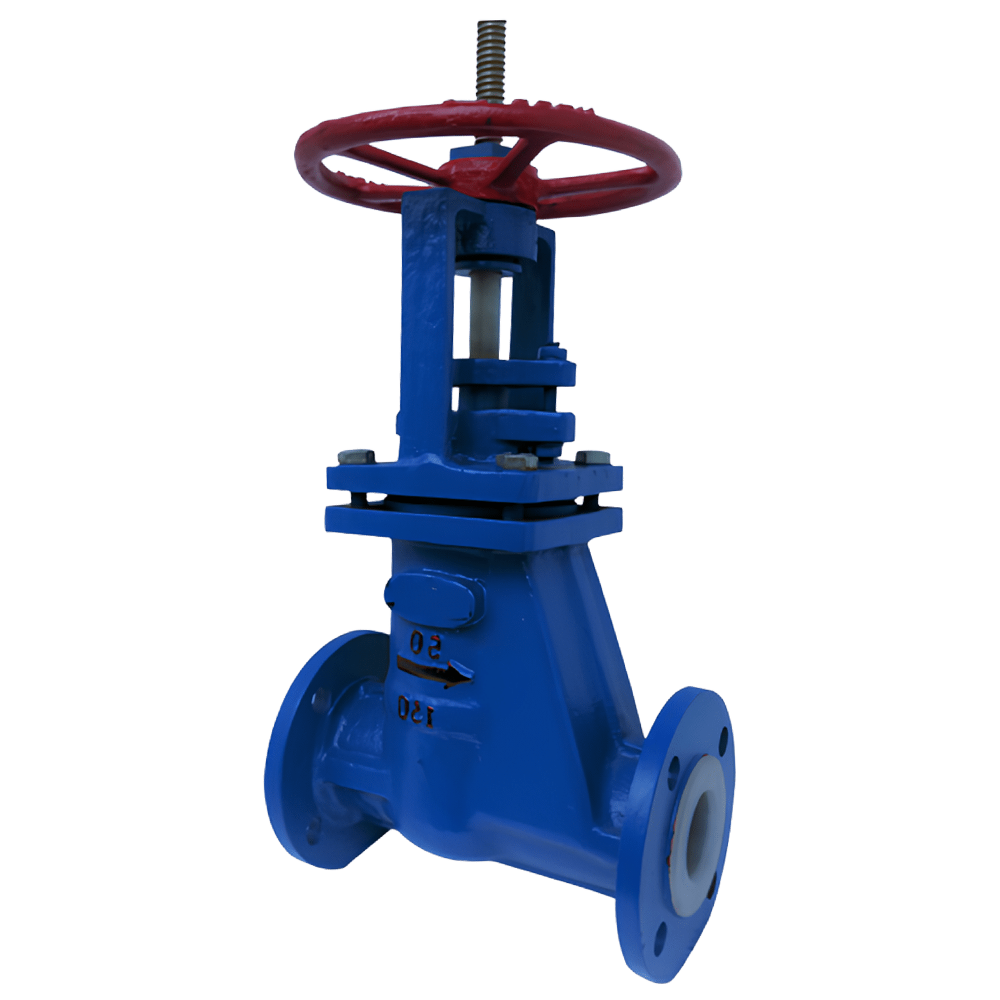

PTFE Lined Plug Valve

PTFE Lined Plug Valve Manufacturer

MVS Valves PTFE Lined Plug Valve is engineered to provide unmatched performance in aggressive and corrosive fluid handling environments. Designed with high-precision casting methods for all pressure-holding components, these valves ensure leak-tight shutoff and long-lasting durability. The valve body, plug, and cover are Carbon Steel (ASTM A216 Gr. WCB), Stainless Steel (ASTM A351 Gr. CF8 / CF8M), or Ductile Iron offered in, making them suitable for a wide range of process conditions.

These fully lined plug valves feature virgin PTFE or PFA linings that are securely locked into the metal body, ensuring zero leakage performance in accordance with Class VI shutoff standards. MVS Valves offers PTFE Lined Plug Valve, PFA Lined Plug Valve, and FEP Lined Plug Valve solutions, all designed for high reliability and resistance against chemicals, acids, and high-temperature media. Available in DN 15 to DN 200 (½” to 8″), with ANSI Class 150 / PN 10–16 ratings, these valves comply with API 599, API 6D, and ISO testing standards.

Our industrial PTFE lined plug valves are ideal for the chemical industry, chlor-alkali systems, and any fluid handling application where acid resistance and corrosion resistance are essential. Whether it’s fluoropolymer lined plug valves, fluoroplastic lined plug valves, or fluorine lined plug valves, every component is designed for maximum performance in aggressive and corrosive applications. We also offer plug valves with PTFE, FEP, and PFA lining, ensuring full compatibility with varying process fluids.

Engineered for bi-directional sealing and featuring a self-lubricating design, the PTFE Lined Cone Valve and Fully Lined Male Valve options are also available for specific use cases. MVS Valves’ product range also includes fluorocarbon resin lined plug valves, plastic lined plug valves, and fluoropolymer lined metal plug valves, all optimized for extended life and high performance under demanding conditions. These reliable and durable lined plug valves are designed to operate with minimal torque and are suitable for high-performance industrial systems.

MVS Valves makes sure that every valve is rigorously tested and built for extended service life, safety, and superior operational efficiency. If your process involves aggressive media, corrosive chemicals, or chlorinated substances, MVS offers the most trusted and high-performance PTFE lined plug valves in the market today.

Specification

| Specification | Details |

|---|---|

| Design Standard | BS 5158:1989 |

| Valve Size | DN 15–DN200 (½″ - 8″) |

| Flange | As per ANSI B16.5 / B16.42 |

| Drilling | ASA #150 / DIN 2632/33 / BS 10 TABLE D, E, F |

| Lining Thickness | 3 to 5 mm |

| Testing Standard | BS EN 12266-1&2 (2003) |

| Test & Inspection - Hydraulic | Body (Shell) – 20 Kg/Cm² Seat – 10 Kg/Cm² |

| Test & Inspection - Pneumatic | Seat – 6 Kg/Cm² |

| Spark Test | 15 KVDC |

| Features | Cavity-less high performance design Zero leakage (Class VI Leakage Rate) due to large sealing area Unique lining makes it fully locked from Top, Bottom & Port Totally maintenance-free design |

| Optional Components | Gear box Pneumatic actuator Jacketed plug valve design Sleeved plug valve design |

Material of Construction

| Body With Lining | Ductile Iron GGG40.3 / ASTM A216 Gr. WCB (FEP Lined) |

| Lined Plug | Ductile Iron / WCB (FEP Lined) |

| Top Cover | Ductile Iron / WCB |

| Lever Boss | ASTM A216 Gr. WCB |

| Lever Rod | M.S. |

| Wedge Ring | PTFE |

| Diaphragm | PTFE |

| Diaphragm Backup | S.S. |

| Thrust Washer | S.S. |

| Stopper Pin | WCB / S.S. |

| Bottom Cover | Ductile Iron / WCB |

| Blind Gasket | PTFE |

| Pusher Bolt | S.S. |

| Pusher Nut | S.S. |

| Grub Screw | S.S. |

| Hex Head Bolt | S.S. |

| Hex Head Bolt Washer | S.S. |

| Blind Gasket Backup | S.S. |

| L. Boss Bolt & Washer | S.S. |

| Body Material Options | Ductile Iron GGG40.3 / ASTM A395 Cast Steel ASTM A216 Gr. WCB ASTM A351 Gr. CF8 / S.S. 304 ASTM A351 Gr. CF8M / S.S. 316 |

| Lining Material Options | PFA – ASTM D 3307 FEP – ASTM D 2116 PVDF – ASTM D 3222 |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia