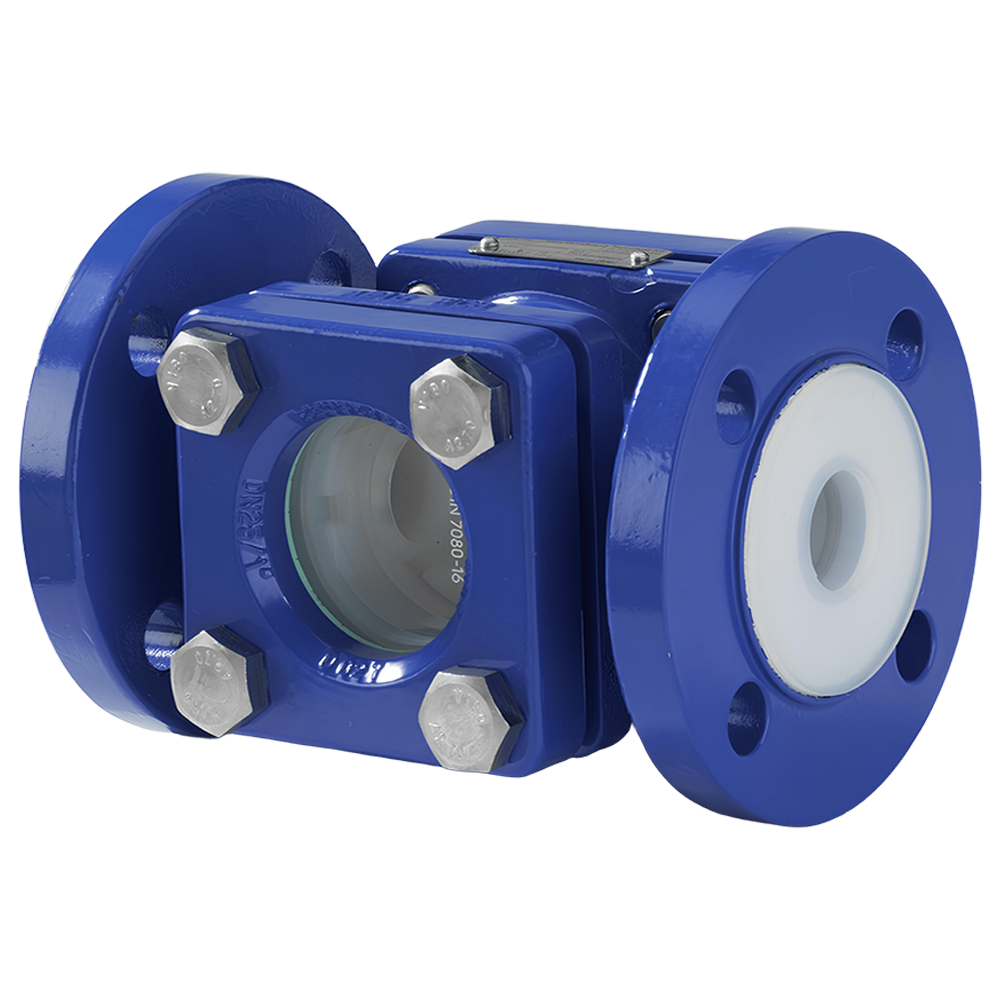

PTFE Lined Sight Flow Indicator

PTFE Lined Sight Flow Indicator Manufacturer

MVS Valves PTFE Lined Sight Flow Indicator is a robust and reliable solution designed for visually monitoring the flow of aggressive and ultra-pure fluids. Built with a fully PTFE/PFA-lined body and durable borosilicate glass viewing windows, this sight flow indicator offers excellent corrosion resistance and high performance under challenging operating conditions. Whether it’s for chemical processing, pharmaceuticals, or ultra-clean fluid applications, this product ensures clear, uninterrupted visibility of media flow.

Engineered to meet the rigorous standards of API 598, ASME B16.34, and EN norms, this indicator guarantees quality, safety, and precision. It is available in a double-window type design, with sizes ranging from ½″ to 6″ (DN 15 to DN150) and flanged end connections conforming to ANSI 150 and PN10–16 pressure ratings. The construction materials include Cast Ductile Iron, Cast Steel, and Stainless Steel, all internally lined with PTFE, PFA, or PVDF to handle a wide range of corrosive media.

It can be installed in any pipeline direction, making it a versatile choice for various industrial applications. The industrial PTFE lined sight flow glass is ideal for continuous flow monitoring in systems where product integrity and chemical resistance are essential. From PFA PTFE Lined Sight Flow Indicators to PVDF PTFE Lined Sight Flow Indicators, MVS offers comprehensive variants tailored to specific operational needs. With advanced design and tested durability, our PTFE Lined Sight Flow Indicator stands out as a dependable component for fluid control systems demanding safety, visibility, and long-lasting performance.

Specification

| Specification | Details |

|---|---|

| Flange | As per ANSI B16.5 / B16.42 |

| Valve Size | ½″ - 6″ (DN 15 - DN150) |

| Lining Thickness | 3 to 5 mm |

| Test & Inspection - Hydraulic | Body (Shell) – 15 Kg/Cm² |

| Test & Inspection - Spark | 15 KVDC |

| Features | Inert to a wide range of corrosive chemicals Eliminates need of using expensive, exotic alloys |

| Optional Components | FULL VIEW (GLASS TUBE) DESIGN |

Material of Construction

| Body With Lining | Ductile Iron GGG40.3 / ASTM A216 Gr. WCB (FEP Lined) |

| Cover Plate | Ductile Iron GGG40.3 / ASTM A216 Gr. WCB |

| Glass | Toughened Glass |

| Cushion | PTFE |

| Bolts | M.S. (Zinc Plated) |

| Nuts | M.S. (Zinc Plated) |

| Body Material Options | Ductile Iron GGG40.3 / ASTM A395 Cast Steel ASTM A216 Gr. WCB ASTM A351 Gr. CF8 / AISI S.S. 304 ASTM A351 Gr. CF8M / AISI S.S. 316 |

| Lining Material Options | PFA – ASTM D 3307 FEP – ASTM D 2116 PVDF – ASTM D 3222 POLYPROPYLENE – ASTM D 4101 |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia