PTFE Lined Wafer Check Valve

PTFE Lined Wafer Check Valve Manufacturer

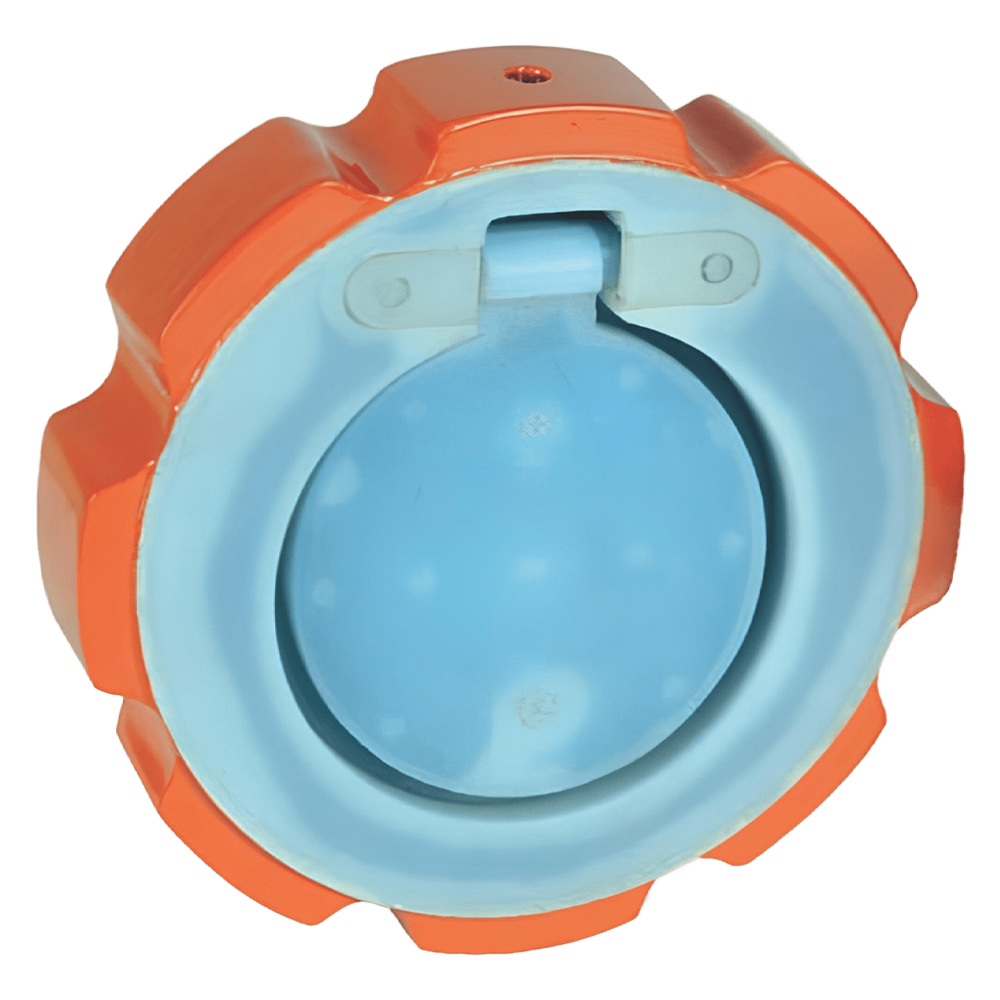

MVS Valves PTFE Lined Wafer Check Valve is a precision-engineered solution designed for maximum reliability in corrosive fluid handling systems. Constructed in a fully lined wafer swing check valve configuration, this valve features a single disc swing type design that fits seamlessly between ANSI B16.5 flanges. Ideal for both vertical and horizontal installations, it offers bubble-tight, bi-directional sealing with PTFE, PFA, or FEP liners to handle highly aggressive or ultra-pure process media.

This lined check valve delivers strong non-return protection and zero leakage for applications in acid transfer lines, chemical processing units, pharmaceutical pipelines, and more. The PTFE lined non return valve is engineered for high performance in systems operating between –20 °C and +180 °C, while ensuring minimal pressure drop and silent operation. With its compact wafer-style body, the valve provides space-saving efficiency without compromising flow capacity or chemical resistance.

Available in sizes ranging from DN 25 to DN 400 (1″ to 16″), the PTFE lined wafer type swing check valve is compliant with API 594 and EN 12334 standards, offering dependable backflow prevention under fluctuating pressures. MVS also offers variations such as the PFA lined wafer swing check valve, PTFE wafer swing check valve, FEP wafer swing check valve, and fluoropolymer lined wafer swing check valves to suit specific industrial needs. These configurations are ideal for fully lined pipeline systems and are especially effective in environments handling corrosive acids, solvents, or hazardous chemicals.

As a trusted PTFE check valve manufacturer and PFA check valve supplier, MVS ensures every valve is rigorously tested for leak-proof performance and structural integrity. From lined wafer swing check valves to full PTFE lined single plate wafer check valves and single door designs, our valves maintain reliable service with no sticking, jamming, or internal cavity accumulation.

Designed for corrosion-resistant, acid-resistant, and chemical-resistant performance, our industrial lined wafer swing check valves are built using high-quality materials such as carbon steel and stainless steel, with a durable lining of fluoroplastics, fluoropolymers, or fluorocarbon resins. These valves meet the toughest industrial standards and are built for extended life in demanding fluid environments.

Whether you’re specifying a wafer swing check valve with PTFE lining or a wafer check valve with PFA or FEP lining, MVS Valves delivers high-quality components that ensure performance, safety, and long-term value. Each valve in this range supports smooth operation, low maintenance, and is tailored for use in aggressive, corrosive, or sterile systems where failure is not an option.

Specification

| Specification | Details |

|---|---|

| Design Standard | BS EN 593:2004 (Formerly BS 5155) |

| Valve Size | DN 25–DN 400 (1″ - 16″) |

| Flange | As per ANSI B16.5 / B16.42 |

| Face to Face | ANSI B16.10 / BS 5155 / ISO 5752 / API 609 / BS EN 558 – 1&2 |

| Lining Thickness | 3 to 5 mm |

| Testing Standard | BS EN 12266-1&2 (2003) |

| Test & Inspection - Hydraulic | Body – 15 Kg/Cm² Back Seat – 2 Kg/Cm² |

| Test & Inspection - Spark | 15 KVDC Spark Test |

| Performance | ΔP (psi) / Leakage Rate: 0–40 psi: 5–10 cc/min 41–74 psi: 3 cc/min 75 & Above: 0 cc/min |

| Special Instruction | Use PTFE Retainer Ring if pipe ID > Max. Inner Pipe Ø in table. Retainer ring ID should match max. pipe ID. |

| Salient Features | Ideal replacement to high alloy valves No Spring or Pin – No corrosion/wear Low pressure drop Special liner locking system for secure seating |

| Optional Components | PTFE Solid Retainer Ring |

Material of Construction

| Body With Lining | Ductile Iron GGG40.3 / ASTM A216 Gr.WCB (FEP Lined) |

| Lined Disc | Ductile Iron GGG40.3 (FEP Lined) |

| Eye Bolt | C.S (Zinc Plated) |

| Body Material Options | Ductile Iron GGG40.3 / ASTM A395 Cast Steel ASTM A216 Gr.WCB ASTM A351 Gr. CF8 / S.S.304 ASTM A351 Gr. CF8M / S.S.316 |

| Lining Material Options | PFA – ASTM D 3307 FEP – ASTM D 2116 PVDF – ASTM D 3322 |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia