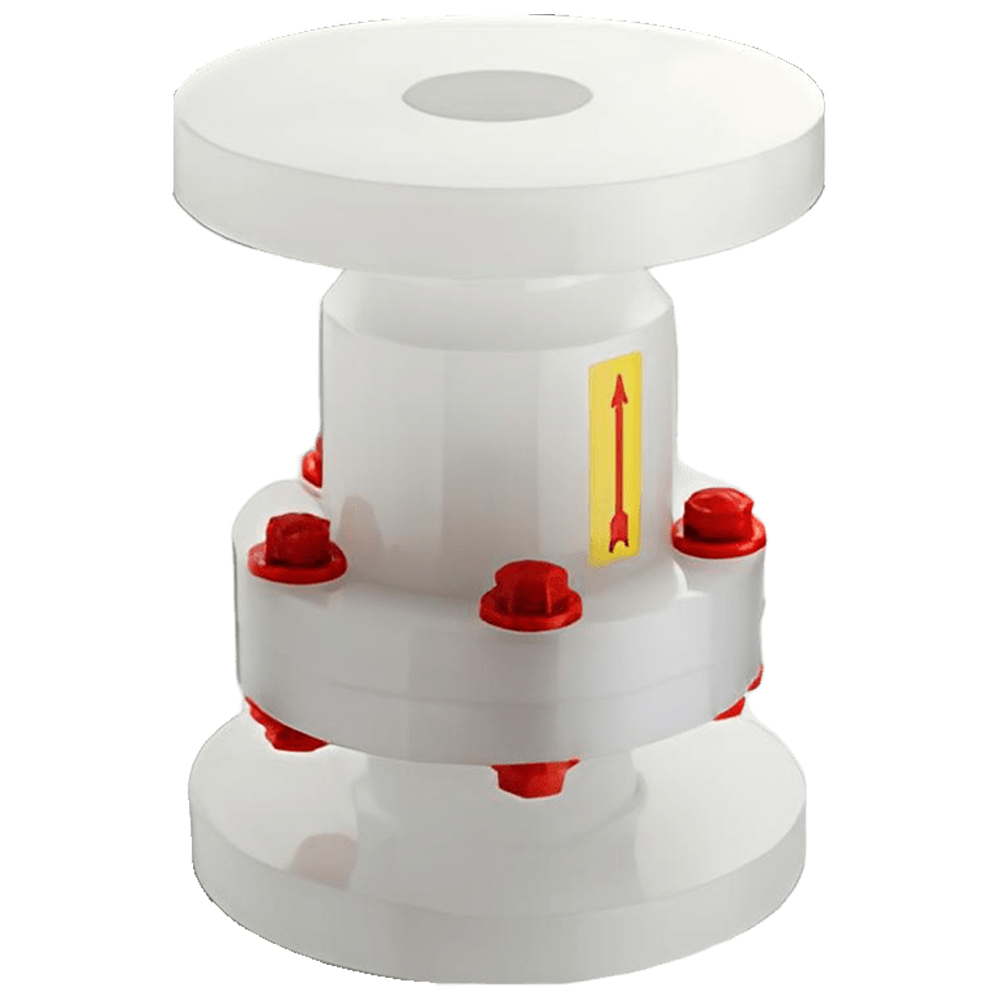

PVDF Ball Check Valve

PVDF Ball Check Valve Manufacturer

The MVS PVDF Ball Check Valve is a precision-engineered, non-return valve designed for use in highly corrosive and chemically aggressive environments. Built in a full bore two-piece construction, this valve operates on a simple yet effective ball-type check mechanism, ensuring unidirectional flow and preventing reverse flow in process pipelines. With options for flanged and screwed end connections, it offers maximum versatility for installation across a wide range of industrial applications.

Constructed entirely from thermoplastic materials like Polypropylene (PP), PPH, and PVDF, this valve stands out for its exceptional resistance to corrosion, even when exposed to the most demanding media. The corrosion resistant thermoplastic ball check valve design ensures longevity, low maintenance, and dependable sealing performance, making it ideal for chemical handling industries.

MVS is a reputed PPH ball check valve supplier and PVDF ball check valve exporter, serving a broad global clientele in sectors. Our polypropylene ball check valve and PVDF variants are specifically tailored to handle aggressive fluids such as sulphuric acid, nitric acid, and hydrochloric acid with complete safety and minimal wear.

Designed for performance in challenging applications, these ball check valves for bromine and chlorine handling are also widely used in systems dealing with sodium hypochlorite, offering enhanced protection through their hydrochloric acid compatible design. Whether your operation involves continuous exposure to corrosive gases or harsh chemical liquids, the MVS PVDF Ball Check Valve offers a robust solution with zero compromise on durability or performance. By integrating chemical resistance, full-flow efficiency, and flexible connectivity, MVS delivers thermoplastic ball type check valves that set the benchmark in industrial non-return valve technology.

Specification

| Specification | Details |

|---|---|

| Construction | 2 Piece Ball Type Design, Soft Seated, Toughened Ball, Full Bore |

| Design Standard | As per Manufacturer’s Standard |

| Size Range | 25 mm to 300 mm (Flanged Ends), 25 mm to 50 mm (Threaded Ends) |

| End Connections | Flanged (ANSI B 16.5 - 150#, BS 10 Table D/E/F, DIN STD), Screwed BSP |

| Hydrostatic Test | 10 kg/cm² for Body and Seat |

Material of Construction

| Component | Material |

|---|---|

| Body Material Options | PP, ISOTACTIC PP, PPH, PVDF |

| Ball Material Options | Solid PVDF / PTFE Ball |

| Seat / Gasket Options | Elastomers: Neoprene, Hyplon, EPDM, Viton (for chemical compatibility) |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

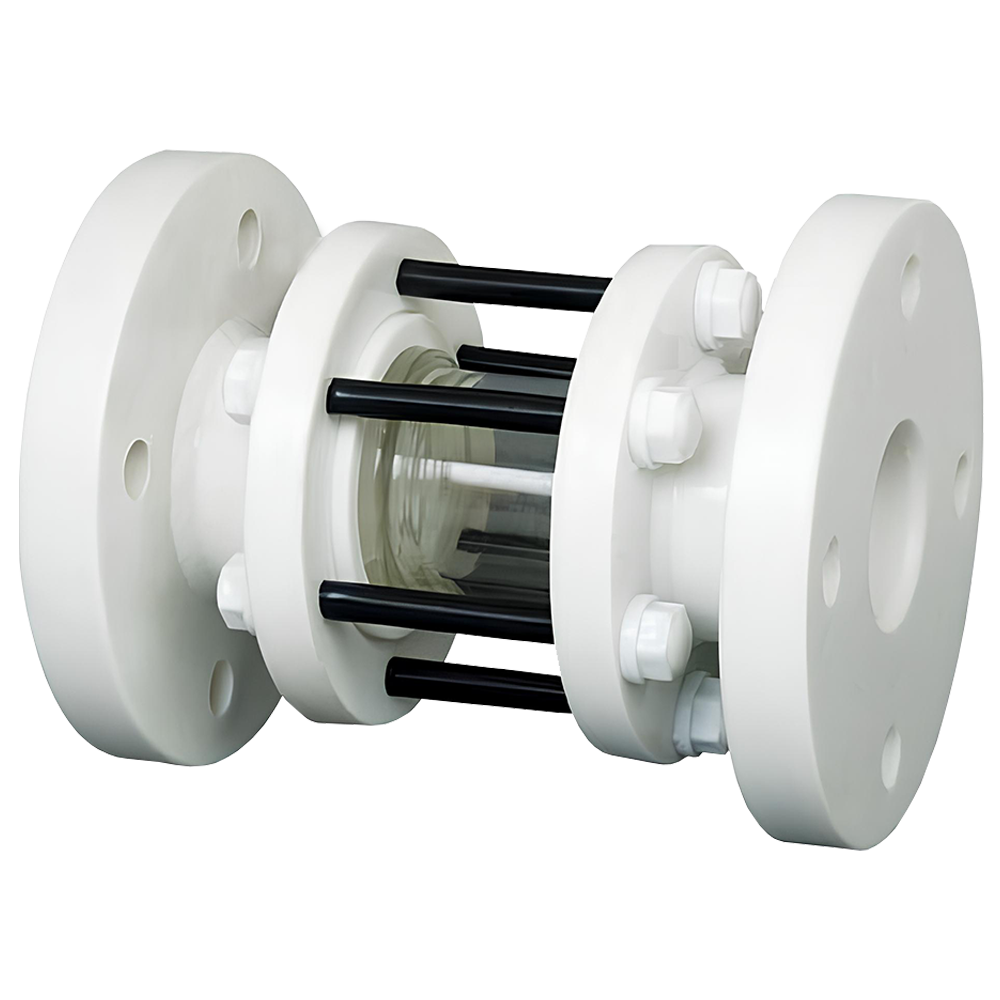

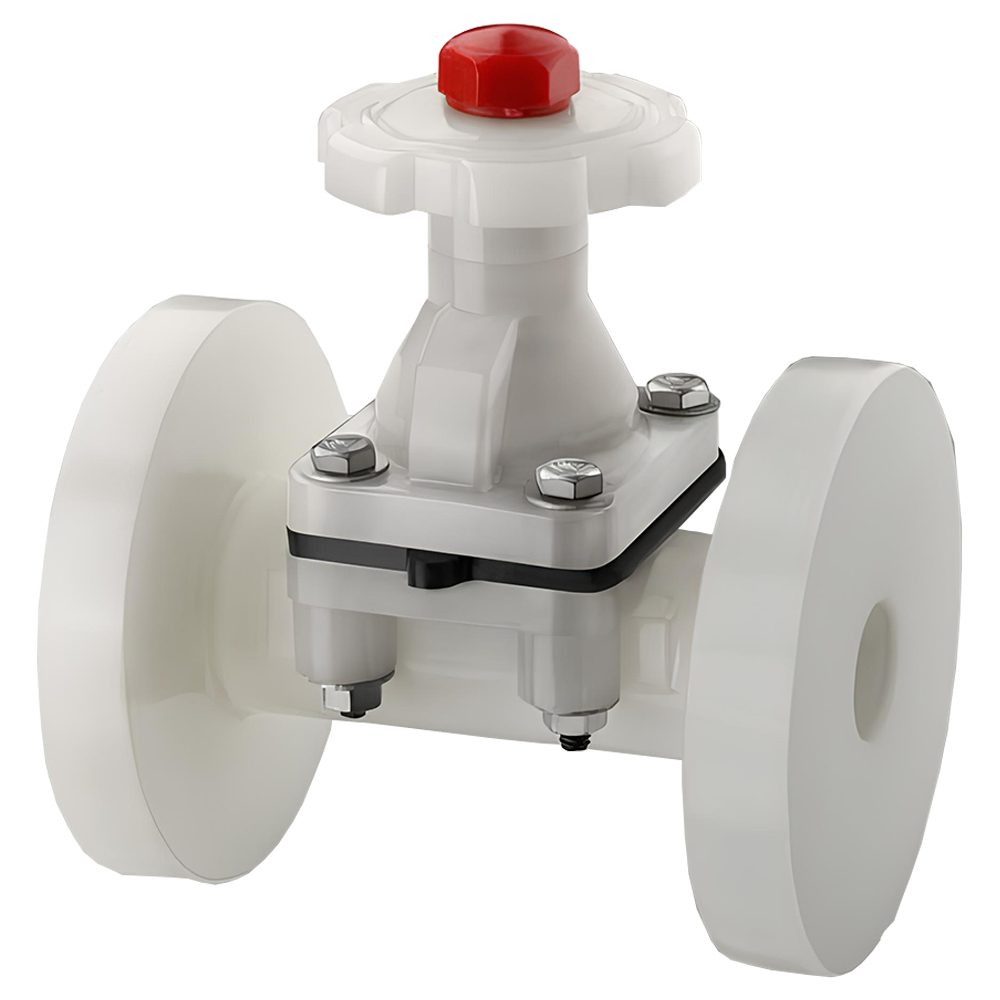

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia