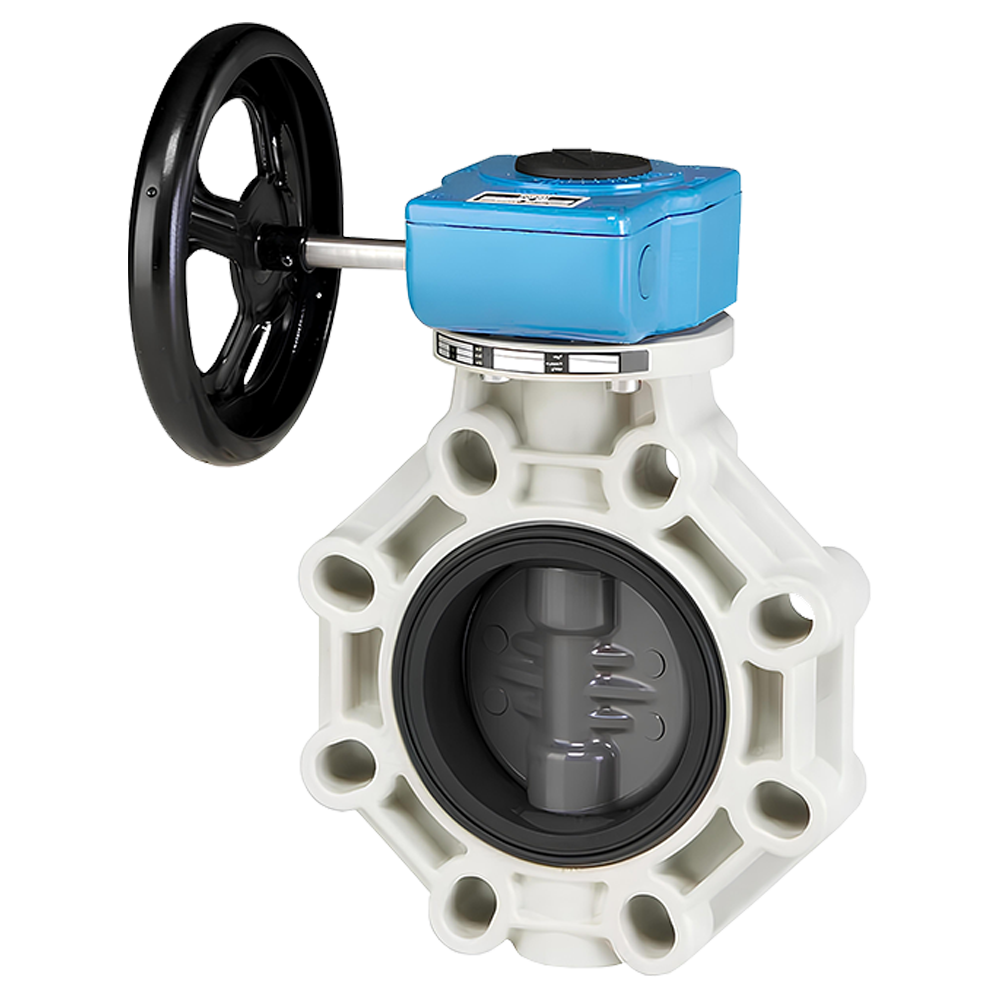

PVDF Butterfly Valve

PVDF Butterfly Valve Manufacturer

The MVS PVDF Butterfly Valve is engineered for demanding industrial applications that require safe and reliable flow control in highly corrosive and chemical environments. Designed in a compact wafer/sandwich style, this corrosion resistant PVDF butterfly valve fits seamlessly between ANSI B16.5 (150#) flanges, providing efficient sealing and optimal space utilization. With size options ranging from 50 mm to 300 mm, it offers flexible integration into diverse process systems.

Manufactured using high-grade PVDF, PP, and PPH materials, the valve delivers exceptional resistance to harsh media such as hydrochloric acid (HCL), nitric acid, sodium hypochlorite, and chlorinated paraffin wax. This makes it a preferred choice across the chemical industry, wastewater treatment facilities, and processing units handling chlorine, acids, and other aggressive fluids.

As a trusted PVDF butterfly valve manufacturer and PP butterfly valve supplier, MVS ensures that each valve is precision-engineered for consistent performance, long service life, and low maintenance. The acid resistant thermoplastic butterfly valve body design minimizes pressure drops while the thermoplastic disc and liner provide secure shut-off and enhanced media compatibility.

For plants looking to safeguard their systems from chemical wear and fluid contamination, MVS offers advanced solutions like the PPH butterfly valve for chemical industry and the chlorine resistant PVDF butterfly valve. The valve is ideal for installations where durability and chemical resistance are non-negotiable, particularly in acid processing lines, industrial effluent systems, and chemical dosing systems. Whether you need a hydrochloric acid resistant butterfly valve or a sodium hypochlorite butterfly valve supplier, MVS stands as a reliable partner in providing robust, high-performance thermoplastic butterfly valves tailored for harsh and specialized applications.

Specification

| Specification | Details |

|---|---|

| Construction | Wafer / Sandwich type, One-Piece Body, Lug Style |

| Design Standard | As per Manufacturer’s Standard |

| Size Range | 50 mm to 300 mm |

| End Connections | Lug Type to suit ANSI B16.5 (150#) flanges |

| Hydrostatic Test | 10 kg/sq.cm.g for Body and Seat |

| Operation | 50–150 mm: Lever Operated, 200 mm: Gear Operated / Pneumatic Actuated |

Material of Construction

| Component | Material |

|---|---|

| Body | PP, Isotactic PP, PPH, PVDF |

| Shaft | S.S. 304 / 316 / 304L / 316L |

| Seat / Liner | EPDM, Neoprene, Viton, Nitrile |

| Disc | PP, PVDF, HDPE, SS (Optional) |

| Sealing | Double-direction sealing with liner acting as flange gasket |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

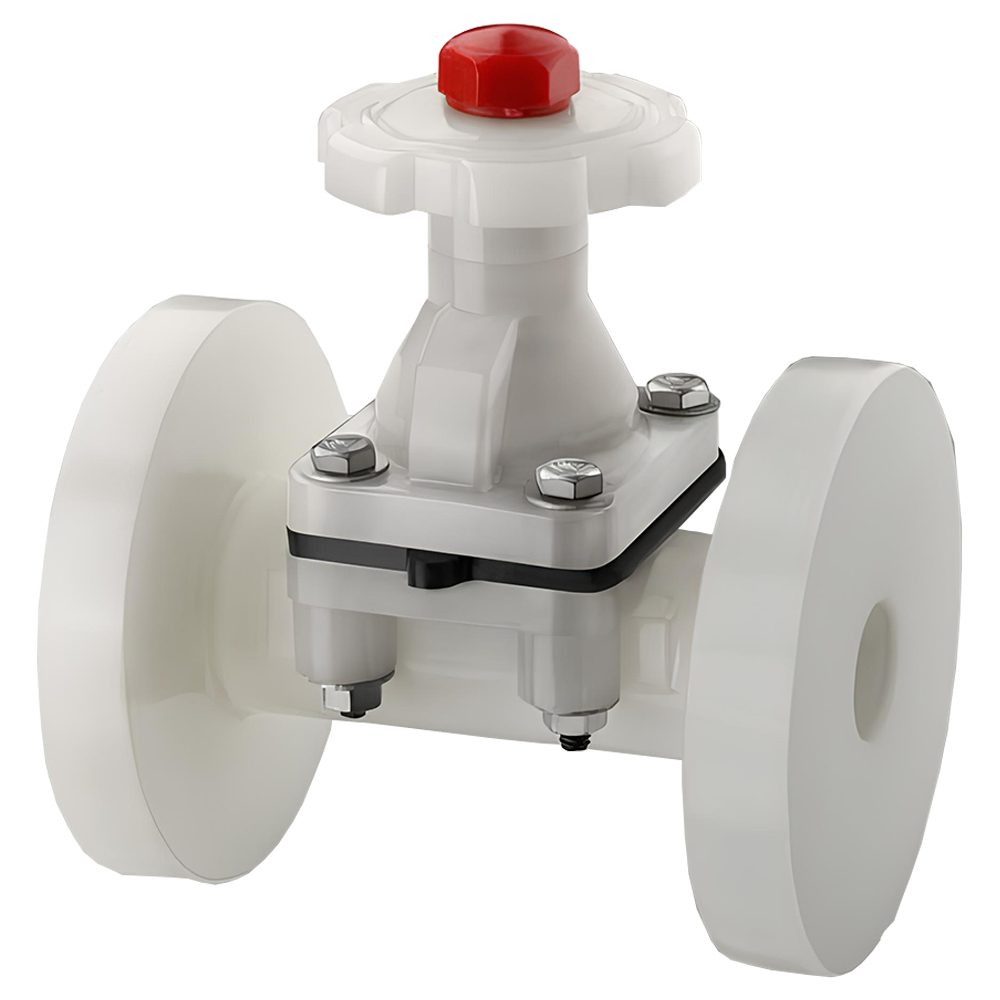

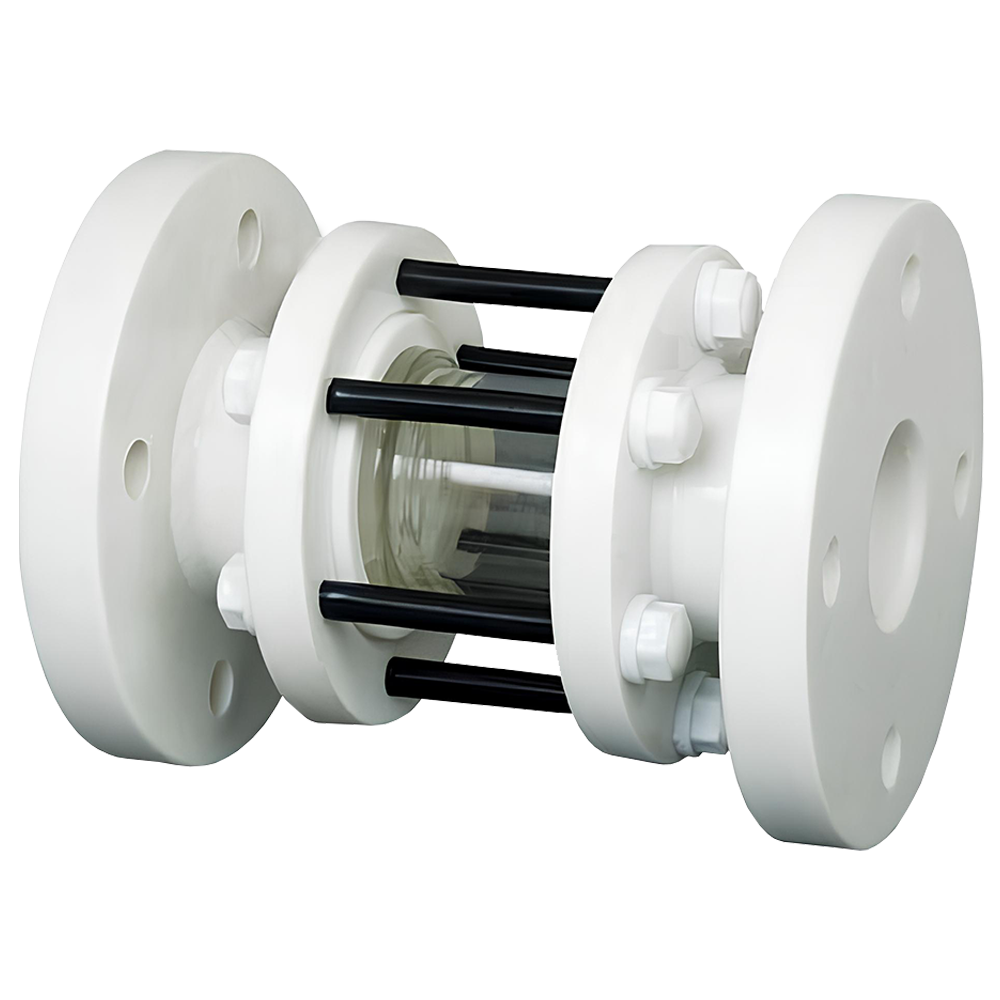

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia