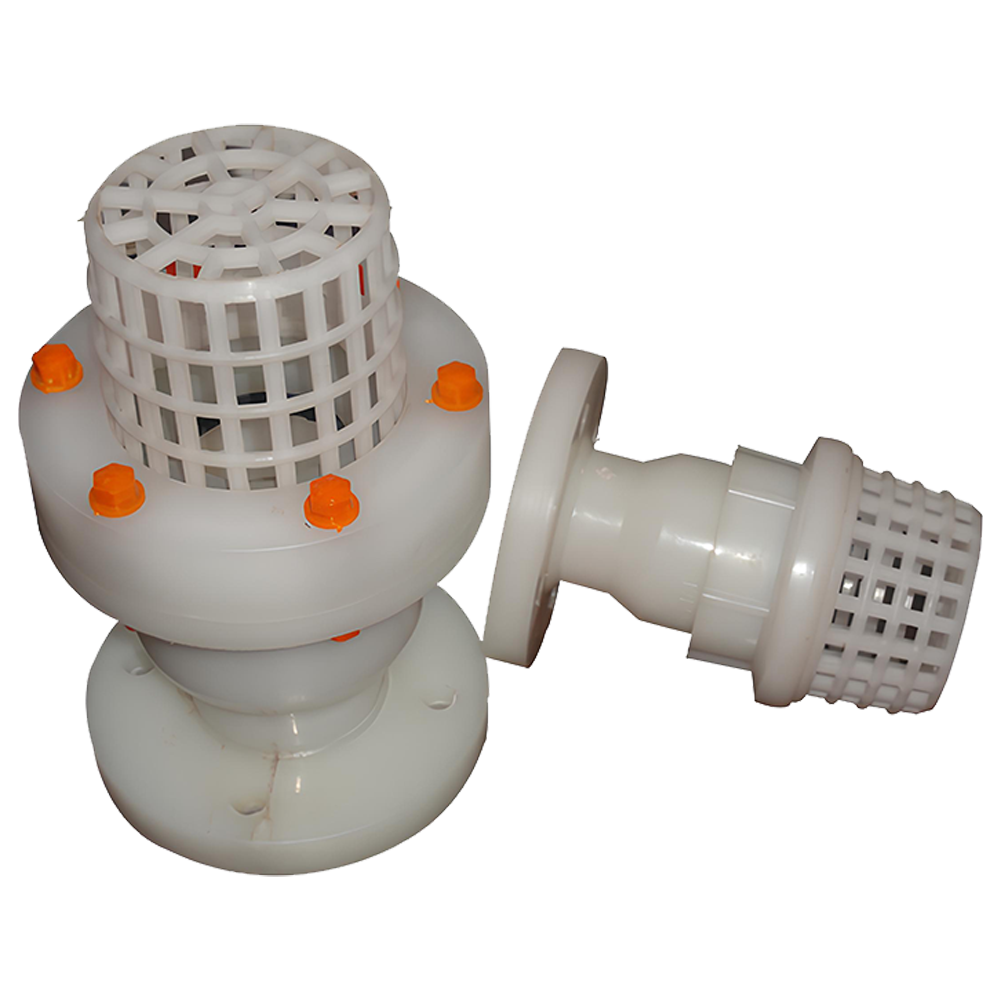

PVDF Foot Valve

PVDF Foot Valve Manufacturer

The MVS PVDF Foot Valve is an essential component for pump suction lines in aggressive chemical environments, combining the dual functionality of a ball check valve and strainer in a single robust unit. Designed in a two-piece full-flow body construction, this thermoplastic foot valve ensures uninterrupted suction performance while preventing backflow and debris entry, protecting pumps from damage and extending their service life.

Constructed using high-performance materials such as PVDF, Polypropylene (PP), PPH, and HDPE, the valve guarantees corrosion resistance even in the harshest media. This corrosion resistant thermoplastic foot valve is engineered with soft-seated, ball-type sealing and optional ceramic/PTFE check balls to enhance chemical compatibility and sealing reliability.

Widely used in chlor alkali plants, chemical process systems, and acid handling units, the PVDF foot valve for chemical industries is ideal for suction-side applications involving sulphuric acid, hydrochloric acid (HCL), and nitric acid. With pressure ratings of PN 10–16 (ANSI 150) and temperature resistance from –20 °C to +120 °C, this valve supports global standards such as DIN, ANSI, and JIS.

Recognized as a trusted acid resistant plastic foot valve manufacturer, MVS offers tailored solutions for industrial clients worldwide. As a leading PPH foot valve supplier and chlor alkali foot valve exporter, we ensure long-lasting, maintenance-friendly valves that perform reliably in high-demand operations.

Specification

| Specification | Details |

|---|---|

| Product Type | PVDF foot valve (check valve + strainer) |

| Size Range | 1″- 12″ (DN 25 - DN300) |

| Pressure Rating | PN 10–16 / ANSI 150 (~10–16 bar) |

| Temperature Range | –20 °C to +120 °C |

| Media | Corrosive and clean liquids |

| Connection Types | Threaded (NPT/BSP), flanged (ANSI/DIN) |

| Standards | ANSI |

| Valve Type | Ball Type Self Operated with Low Cracking Pressure |

Material of Construction

| Body Material Options | PP (Polypropylene), ISOTACTIC PP, PPH, PVDF, HDPE |

| Ball Material Options | Solid PVDF / PTFE Ball |

| Seat / Gasket Options | Elastomers: Neoprene, Hypalon, EPDM, Viton for chemical compatibility |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

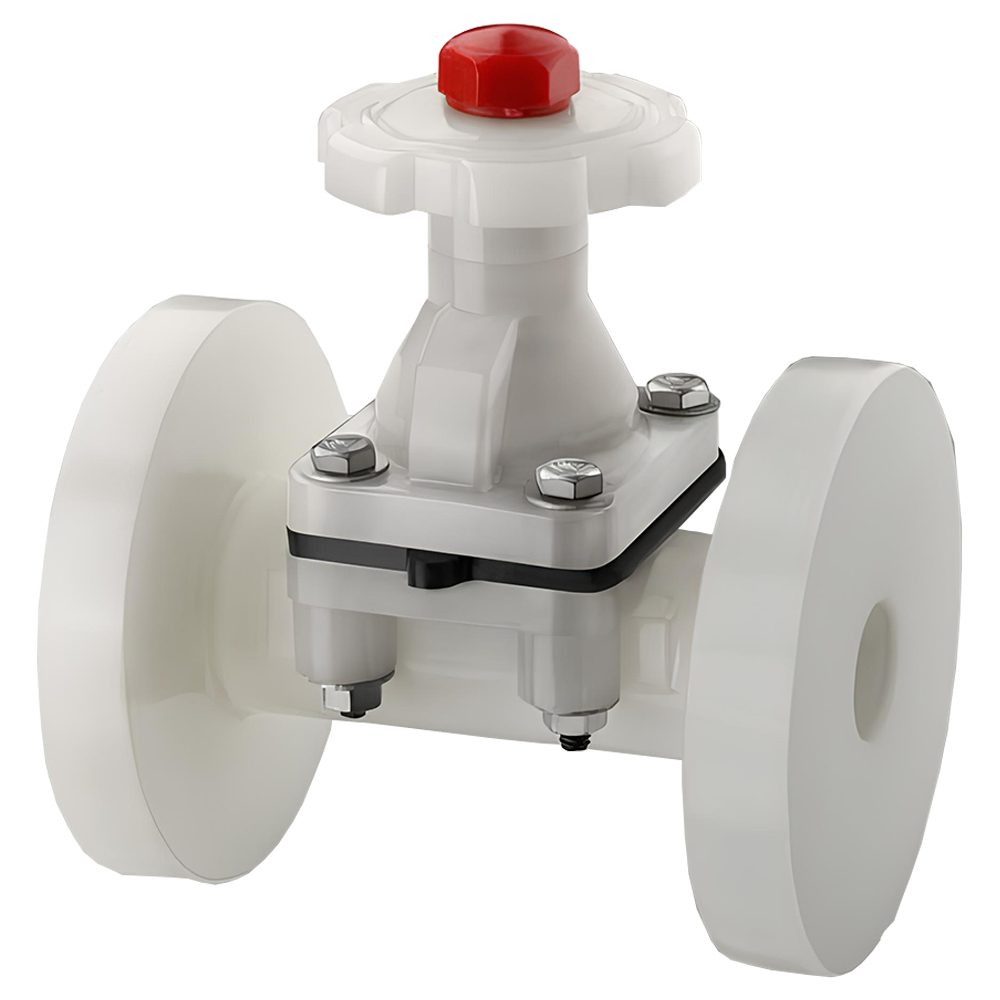

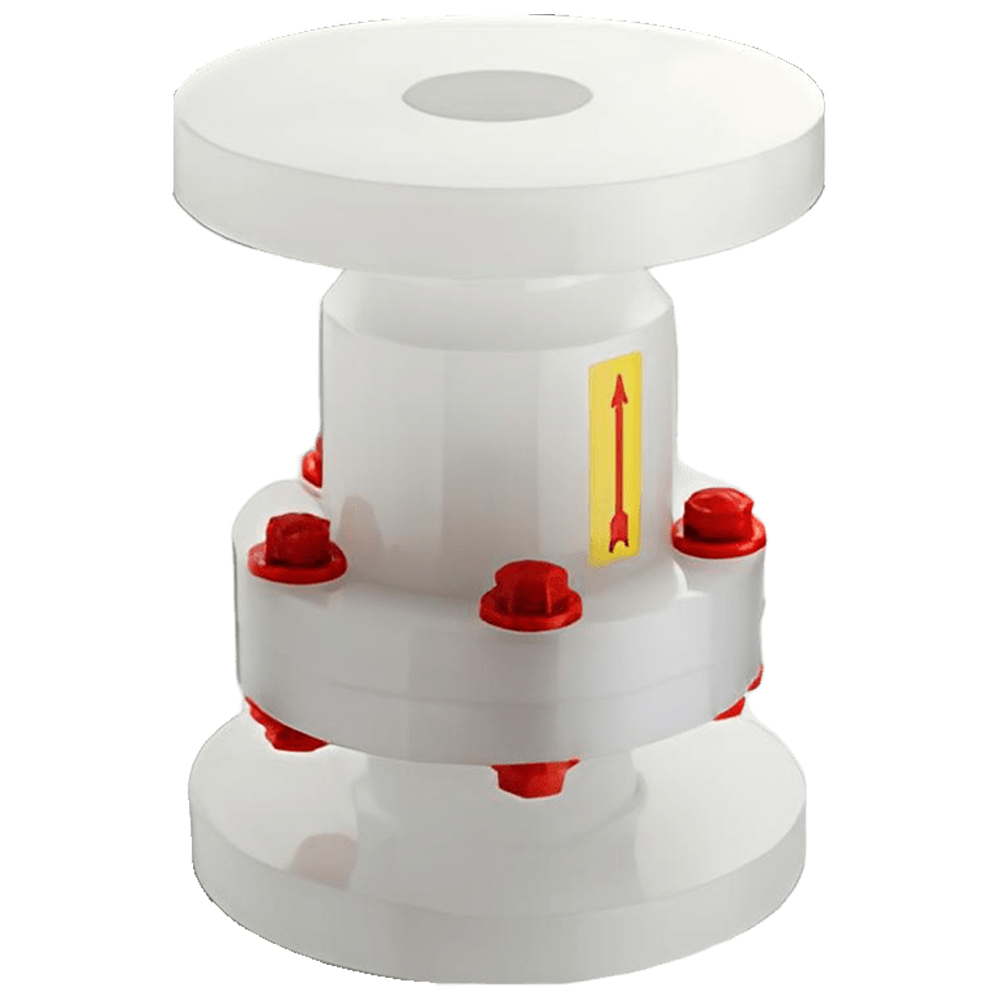

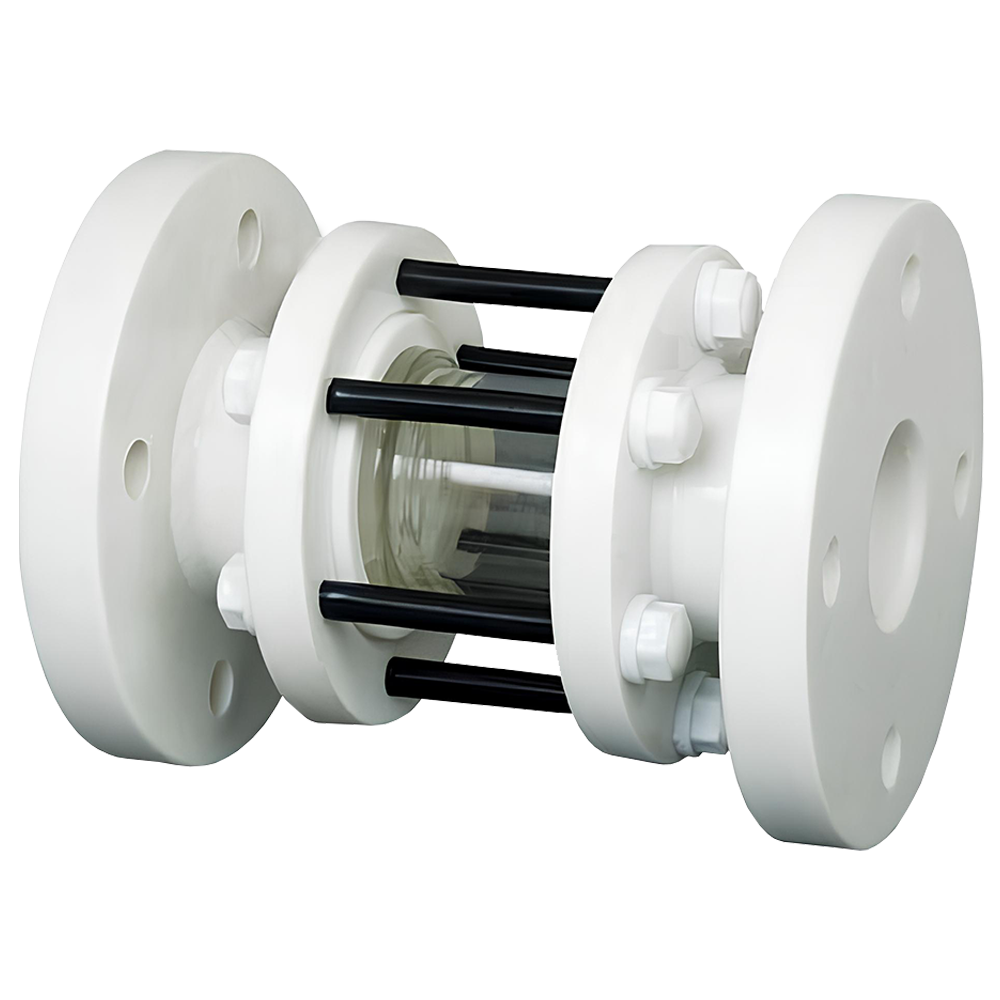

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia