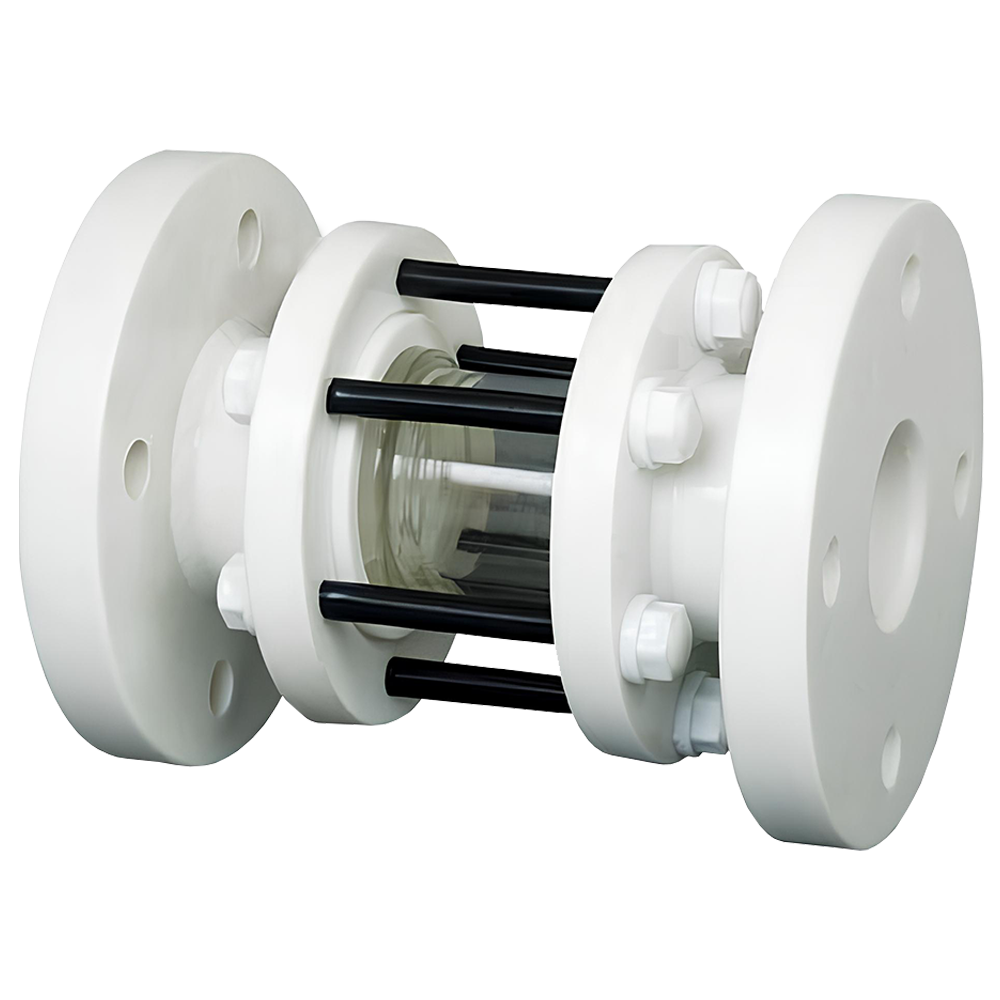

PVDF Sight Glass

PVDF Sight Glass Manufacturer

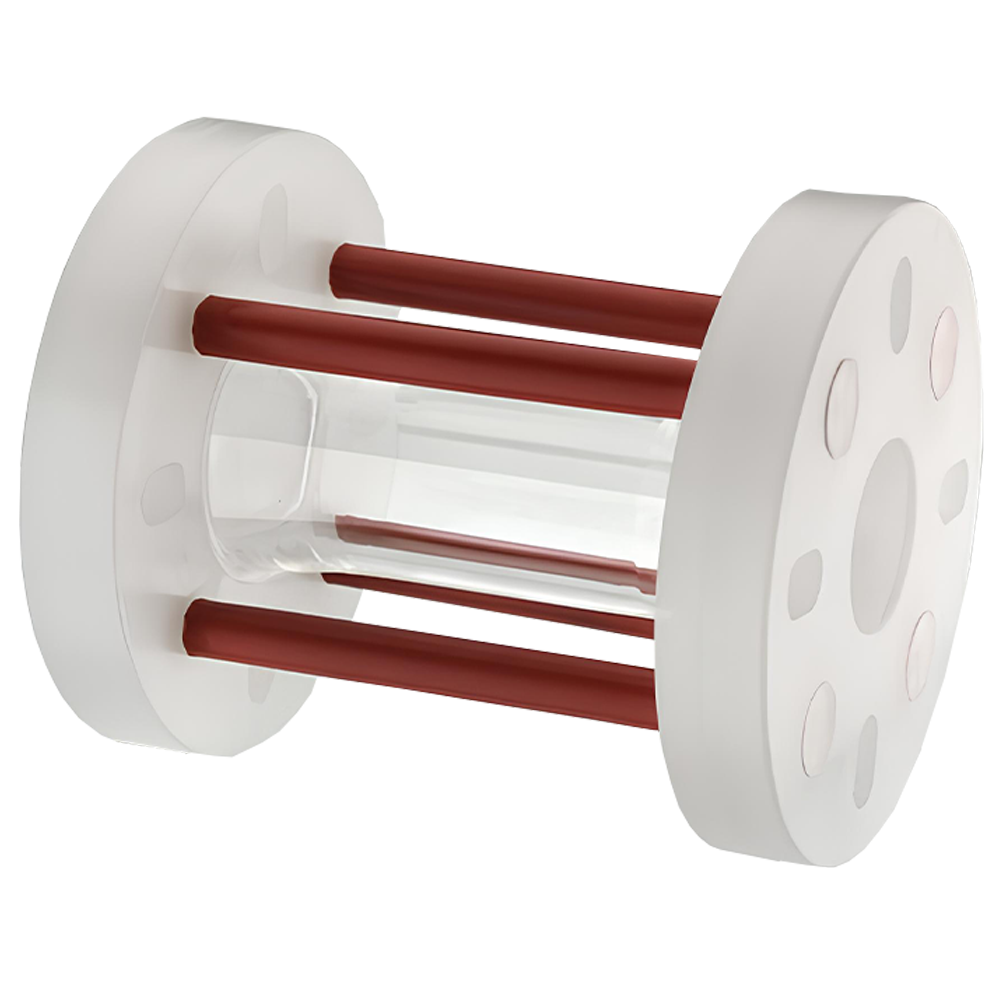

The MVS PVDF Sight Glass is a high-clarity visual inspection solution engineered for aggressive chemical environments. Designed with full PVDF housing and a durable borosilicate glass tube, this unit ensures 360° visibility for safe and continuous monitoring of fluid flow. With a three-piece sturdy construction, it provides a wide viewing area for operators to clearly observe flow conditions in corrosive pipelines, helping to prevent process interruptions or failures.

This corrosion resistant thermoplastic sight glass is available in sizes ranging from DN 15 to DN 150 (½″ to 6″) and is compatible with ANSI and DIN flange standards, pressure rated up to PN 16 (~10 bar), and capable of withstanding temperatures between –20 °C and +120 °C. Whether it’s handling water, acids, bases, or ultra-pure chemicals, this chlorine resistant thermoplastic PVDF sight glass offers excellent chemical compatibility and mechanical strength under demanding conditions.

The chemical resistant polypropylene sight flow indicator and PPH sight glass supplier options make MVS Sight Glass ideal for viewing media such as sulphuric acid, nitric acid, hydrochloric acid (HCL), and chlorine-based solutions. Its tubular construction ensures low pressure drop and is commonly used in chlor alkali systems, bromine handling lines, and sodium hypochlorite flow indicators.

Engineered for long service life and low maintenance, the PVDF sight flow indicator from MVS is built to meet global safety and quality standards. It enables safe visual control over flow and filling in process lines, ensuring reliable and clear operation even in the most chemically aggressive environments.

Specification

| Specification | Details |

|---|---|

| Product Type | PVDF tubular sight glass |

| Size Range | ½″–6″ (DN 15–150) |

| Pressure Rating | PN 10–16 (~10 bar); ANSI 150# |

| Temperature Range | –20 °C to +120 °C |

| Connections | ANSI B16.5 / DIN EN 1092‑1 flanges |

| Glass Tube | Borosilicate (“heavy-wall”) |

| Seals | EPDM or FKM O-rings |

| Orientation | Horizontal or vertical installation |

| Standards | DIN/ANSI, vacuum-rated equivalent to pressure rating |

Material of Construction

| Body Material Options | PP (Polypropylene), ISOTACTIC PP, PVDF (Poly-Vinyli-dene-Fluoride) |

| Glass Tube | Toughened Glass (Standard Lengths: 4", 6") |

| Seat / Seal Options | PTFE Seals or Elastomer Seals (for aggressive chemical compatibility) |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

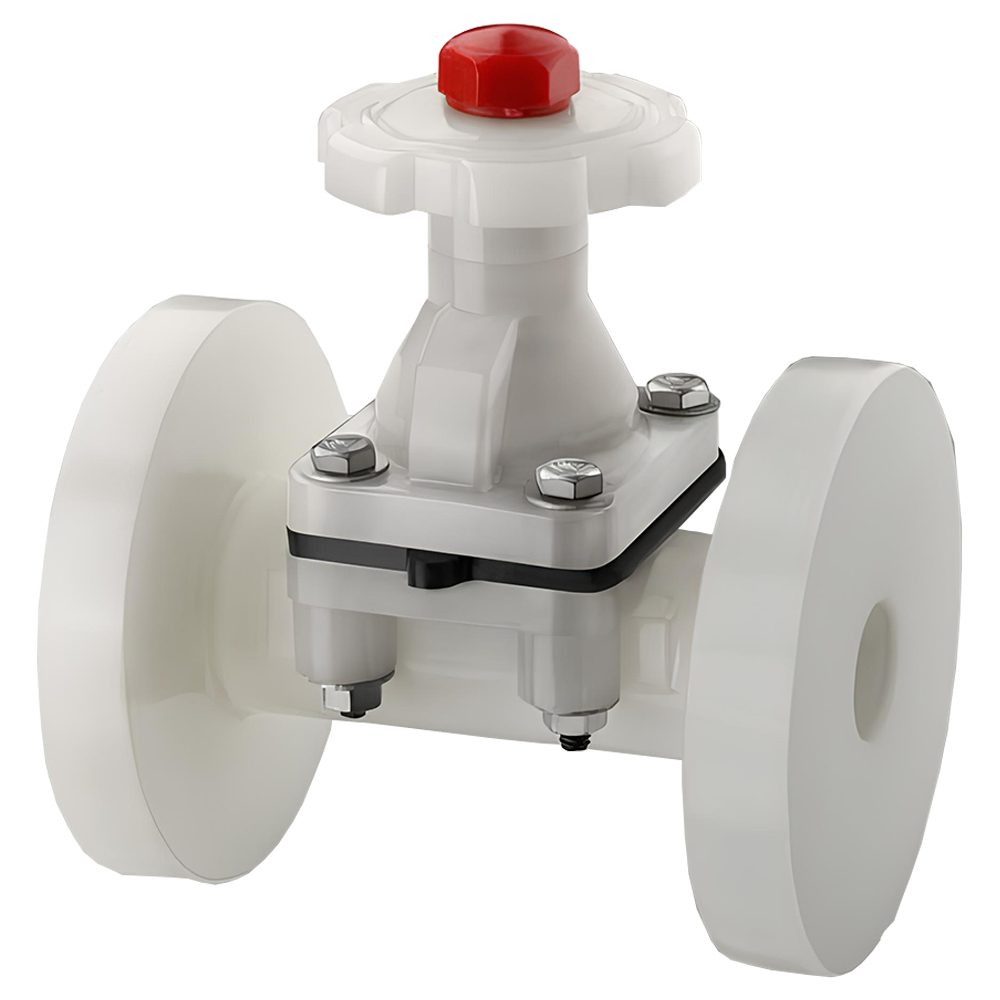

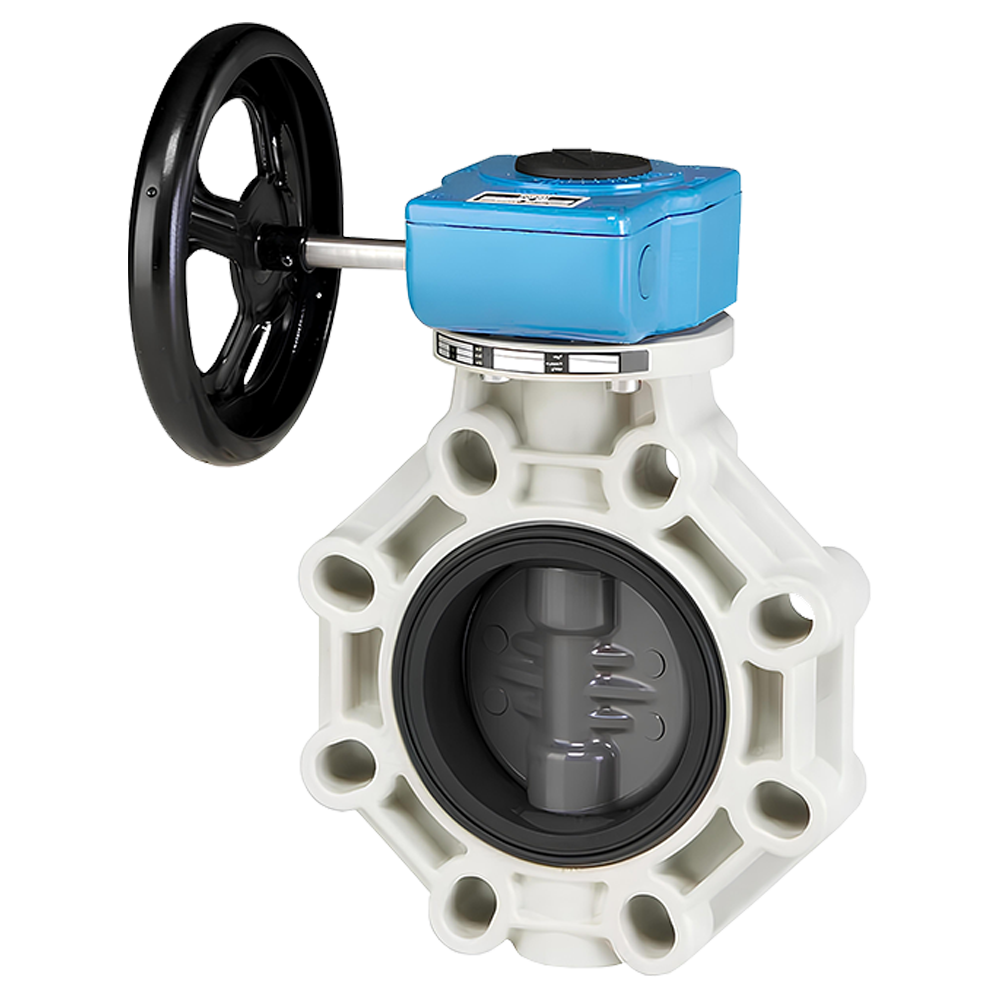

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia