When you run a plant, every small decision affect safety, output, and cost. One weak valve can slow production, cause leaks, or stop a full line. That’s why choosing the right valve is not a small task. If you work with heavy fluids, steam, gases, or critical process lines, you already know how much pressure a valve takes every day. This is where a lubricated plug valve proves its value. And this is also where Mayur (Valves)System Private Limited comes into the picture.

If you’re searching for a long-term solution that works smoothly, seals tightly, and stays reliable under tough conditions, this guide will help you. Here you’ll learn what a lubricated plug valve is, where it is used, why industries trust it, and why Mayur (Valves)System Private Limited stands out as a reliable partner.

Understanding Lubricated Plug Valves in Simple Terms

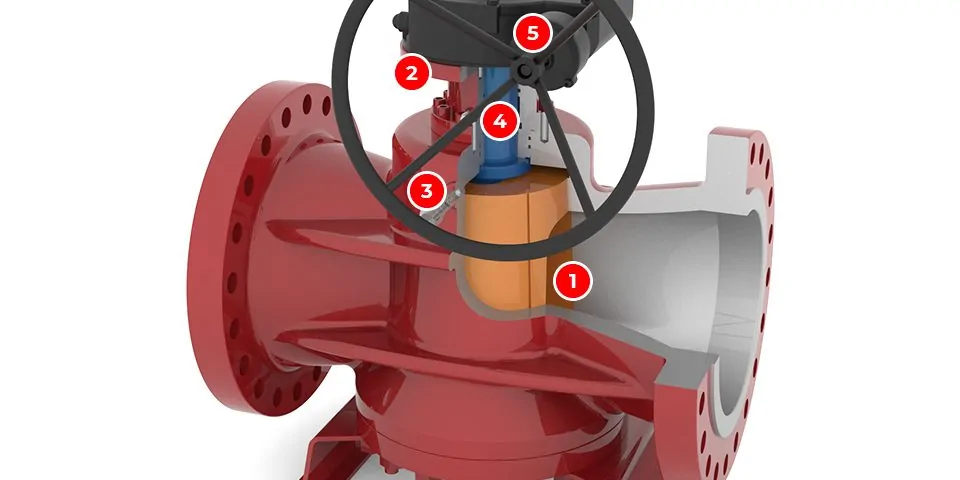

A lubricated plug valve is built for tough jobs. It uses a tapered or cylindrical plug that rotates inside the valve body. A special lubricant is injected between the plug and body. This lubricant reduces friction, improves sealing, and protects internal parts from wear. Because of this design, the valve works smoothly even under high pressure and high temperature.

Industries prefer this type of valve because it handles thick fluids, dirty media, and aggressive chemicals without losing performance. Many buyers look for a reliable Lubricated Plug Valve Manufacturer because quality matters more here than in most other valve types. A poor build can fail fast. A strong build can run for years with simple care. At Mayur (Valves)System Private Limited, these valves are designed for real industrial conditions. They are made to work in lines where you cannot afford leaks or frequent shutdowns.

Why Lubrication Matters in Plug Valves

In many process lines, metal parts rub against each other thousands of times a year. Without lubrication, friction increases, operation becomes hard, and sealing becomes weak. The main advantage of a lubricated plug valve is the continuous lubrication layer between the plug and body. This layer keeps the valve easy to operate and also fills small gaps, which improves tight shut-off.

This is one reason why INDUSTRIAL METAL SEATED LUBRICATED TAPER PLUG VALVES are widely used in heavy-duty applications. Metal seating gives strength. Lubrication gives smooth movement and better sealing. Together, they create a valve that works in extreme conditions without frequent issues.

Types of Lubricated Plug Valves You Can Choose

Different plants have different needs. Flow rate, space, pressure, and media type all matter. That’s why Mayur (Valves)System Private Limited offers multiple designs to match real working conditions. One important option is the Steam Jacketed Lubricated Taper Plug Valve. This type is used where the fluid can harden or crystallize. The steam jacket keeps the valve body warm, so the media stays in a flowing state. This is very useful in chemical, bitumen, and heavy oil lines.

Another common choice is the REGULAR PATTERN INVERTED CARBON STEEL LUBRICATED TAPER PLUG VALVES. This design supports stable flow and strong sealing. Carbon steel body gives strength, and the regular pattern suits standard pipeline layouts. For places where space is limited, many users prefer the short pattern carbon steel lubricated taper plug valves. They save space without cutting down on performance. When installation length matters, this option makes work easier.

There is also the regular pattern carbon steel lubricated taper plug valves option. This is widely used in general industrial service. It offers a good balance between size, flow, and strength, which makes it suitable for many plants. All these types are part of the range supplied by Mayur (Valves)System Private Limited, and each one is built to match strict industrial needs.

Where These Valves Are Commonly Used

Lubricated plug valves are not limited to one or two industries. You’ll find them in oil and gas plants, chemical factories, refineries, power plants, and even in some food processing units where heavy or sticky fluids move through pipelines. They are often used in lines carrying oils, steam, gases, solvents, resins, and other process fluids. Many chemical processes need tight shut-off and smooth operation. That’s where industrial metal seated lubricated taper plug valves and steam jacketed lubricated taper plug valve designs become very useful.

In refineries and petrochemical plants, these valves handle hydrocarbons and high-temperature fluids. In chemical plants, they work with acids, alkalis, and other reactive materials. In power plants, they control steam and other process media. Because of this wide use, choosing the right Lubricated Plug Valve Manufacturer becomes a serious decision, not just a purchase.

How These Valves Help Your Plant Work Better

Every plant manager wants three things. Less downtime. Less maintenance. More stable operation. A good, lubricated plug valve supports all three goals. First, the lubrication system reduces wear. This means the valve lasts longer and needs fewer repairs. Second, the tight sealing reduces leakage. This improves safety and also saves product. Third, the simple quarter-turn operation makes control fast and easy, even in large size valves.

When you use well-built regular pattern carbon steel lubricated taper plug valves or short pattern carbon steel lubricated taper plug valves, you also reduce installation and alignment problems. The valve fits better into your system and works without extra stress on the pipeline.

Why Material Choice Matters So Much

In industrial valves, material is not just a detail. It decides strength, life, and safety. Carbon steel is widely used because it gives a strong balance between cost and performance. That’s why many plants choose regular pattern inverted carbon steel lubricated taper plug valves and regular pattern carbon steel lubricated taper plug valves for daily operation.

Metal seating is also important. It allows the valve to handle high temperature and pressure without damage. When combined with proper lubrication, metal seating becomes both strong and reliable. This is one reason industrial metal seated lubricated taper plug valves are trusted in demanding lines.

Choosing the Right Valve for Your Process

Before buying, it’s always smart to look at your process conditions. Think about pressure, temperature, type of fluid, and how often the valve will operate. If the media can solidify, a steam jacketed lubricated taper plug valve may be the right choice. if space is tight, a short pattern carbon steel lubricated taper plug valves design can help.

if you need a standard, strong solution for general service, regular pattern carbon steel lubricated taper plug valves or regular pattern inverted carbon steel lubricated taper plug valves are often the right fit. Working with an experienced Lubricated Plug Valve Manufacturer makes this decision easier. They can guide you based on real working conditions, not just catalog data.

The Role of a Trusted Manufacturer

A valve is not just a product. It is a safety component. A failure can stop production or cause serious damage. That’s why so many industries prefer to work with Mayur (Valves)System Private Limited. The company focuses on industrial needs and builds valves that match real site conditions. As a Lubricated Plug Valve Manufacturer, Mayur (Valves)System Private Limited understands what industries expect. The focus stays on solid construction, correct material selection, and reliable sealing. This approach helps customers run their plants with fewer worries and better control.

Global Supply of Lubricated Plug Valves for Industrial Projects Worldwide

Today, industrial projects don’t stop at borders, and neither does Mayur (Valves)System Private Limited. Our lubricated plug valves support critical operations in Australia, the United States, USA, Canada, Mexico, and across Europe, including Germany, France, Italy, Spain, Netherlands, Belgium, Poland, Austria, Czech Republic, Romania, Sweden, Finland, Denmark, the UK, Ireland, Greece, and the wider European Union. We also serve major energy and process industries in the Middle East, including United Arab Emirates, Saudi Arabia, Qatar, Oman, Kuwait, Bahrain, Jordan, and Israel.

while supporting growing industrial markets in Africa such as South Africa, Egypt, Nigeria, Kenya, Morocco, Tunisia, Tanzania, Ethiopia, and Uganda. Our presence extends across Asia-Pacific with trusted supplies to Japan, South Korea, Indonesia, Vietnam, Malaysia, Thailand, Philippines, Singapore, Sri Lanka, and New Zealand, and further into Central Asia, Eastern Europe, and the Americas, including Kazakhstan, Uzbekistan, Kyrgyz Republic, Azerbaijan, Turkey, Brazil, Argentina, Chile, Colombia, Costa Rica, Panama, Guyana, and Trinidad & Tobago. This global trust proves that our industrial metal seated lubricated taper plug valves, steam jacketed lubricated taper plug valve, and carbon steel designs perform reliably across different standards, climates, and industrial demands.

Wide Range of Valve Body Materials for Every Industrial Condition

Every industry works under different pressure, temperature, and chemical conditions, and that’s why material selection plays a direct role in valve life and plant safety. Mayur (Valves)System Private Limited offers lubricated plug valves in a wide range of proven valve body materials to match real working environments. Our supply program includes ASTM A351 CF8M 316 stainless steel, ASTM A216 WCB carbon steel, ASTM A216 LCB, ASTM A351 CF3M 316L low carbon stainless steel, ASTM A351 CF8 304 stainless steel, ASTM A351 CF3 304L low carbon stainless steel, ASTM A351 CN7M Alloy 20, ASTM A296 CW-12M Hastelloy C, and ASTM A296 M-35 Monel. Each of these materials is selected to handle specific challenges such as corrosion, high temperature, pressure, and aggressive media found in oil and gas, chemical, petrochemical, and power plants.

Along with these specific grades, Mayur (Valves)System Private Limited also supplies valves in a wide range of material categories to meet different international project requirements. These include carbon steel, low temperature carbon steel, low alloy steels, 13 percent chromium stainless steel, austenitic stainless steel, precipitation hardening stainless steel, duplex and super duplex stainless steel, bronze, nickel alloys such as 825, 625, and 718, and titanium. This wide material range allows customers to choose the exact combination of strength, corrosion resistance, and temperature stability needed for their process, without changing plant design or compromising long-term reliability.

Why Choose Us

Mayur (Valves)System Private Limited is trusted because the company keeps its focus on practical performance, not just on selling a product. Each valve is designed for real industrial use, tested for strength, and built to handle tough conditions. The team understands how industrial metal seated lubricated taper plug valves, steam jacketed lubricated taper plug valve, regular pattern inverted carbon steel lubricated taper plug valves, short pattern carbon steel lubricated taper plug valves, and regular pattern carbon steel lubricated taper plug valves work in actual plants. This experience helps customers get the right solution, not just a standard item. With Mayur (Valves)System Private Limited, you get reliable products, clear guidance, and long-term support.

Conclusion

Choosing the right valve improves safety, reduces downtime, and keeps your process stable. A lubricated plug valve is a smart choice for heavy-duty, high-pressure, and high-temperature lines. It offers smooth operation, tight sealing, and long service life. When you work with Mayur (Valves)System Private Limited, you work with a team that understands industrial needs and builds valves that match real conditions. From standard lines to special applications, their range covers every major requirement. If you want a dependable solution that supports daily operation without trouble, this is a choice that brings long-term value and peace of mind to your plant.

Key Takeaways

- A lubricated plug valve gives smooth operation and strong sealing for tough industrial lines.

- Metal seated and carbon steel designs handle high pressure and temperature with stability.

- Steam jacketed designs help in processes where media can harden or solidify.

- Short and regular pattern valves help match space and layout needs.

- Working with Mayur (Valves)System Private Limited gives your reliable products and clear technical support.

Looking to buy a reliable lubricated plug valve for your plant? Call +91 9998920298 or email mayurvalves@gmail.com to connect with Mayur (Valves)System Private Limited and get the right solution today.

FAQs

What is the main use of a lubricated plug valve?

It is used to control flow in high-pressure or heavy-duty lines where smooth operation and tight shut-off are required.

Where is a steam jacketed lubricated plug valve used?

It is used where the fluid can harden or crystallize, such as in chemical or heavy oil processes.

Why are carbon steel bodies common in these valves?

Carbon steel gives strong mechanical strength and works well in many industrial conditions.

How often does a lubricated plug valve need maintenance?

With proper lubrication, it needs less frequent maintenance compared to many other valve types.

Why should I choose Mayur (Valves)System Private Limited?

Because the company focuses on industrial performance, reliable design, and practical solutions for real plant conditions.