PTFE Lined Pipe Fittings Manufacturer & Exporter

As a trusted PTFE Lined Pipe Manufacturer, MVS Valves offers premium-quality lined pipe systems designed for safe and long-lasting fluid transport in chemically aggressive and high-purity environments. Our PTFE-Lined Pipes combine the chemical inertness of virgin PTFE with the structural integrity of carbon steel or stainless steel, making them ideal for handling acids, alkalis, solvents, and other corrosive fluids. Manufactured in sizes ranging from ½″ to 24″ (DN 15–600), these pipes are pressure-rated for ANSI Class 150/300 or PN 10–25, and operate reliably in temperatures between –40 °C to +230 °C. Fully compliant with ASTM F1545, ASME B16.5, and ISO standards, our PTFE lined pipes are vacuum-rated and tested to ensure zero leakage and absolute process integrity.

Our PTFE lined pipe systems are engineered using high-grade carbon steel or stainless steel, tailored to the demands of various industries like chemical processing, pharmaceuticals, acid manufacturing, wastewater treatment, and chlor-alkali plants. Each spool is internally lined with seamless, paste-extruded PTFE, offering superior permeation resistance and long service life even under severe operating conditions. Whether you require straight pipe spools or need integration with PTFE-lined fittings, valves, and instrumentation, MVS Valves delivers a comprehensive, high-performance solution that minimizes downtime and maximizes safety. If you're looking for a reliable, corrosion-proof solution for aggressive fluids, choose MVS Valves—your go-to PTFE Lined Pipe Manufacturer with a proven track record of quality and innovation.

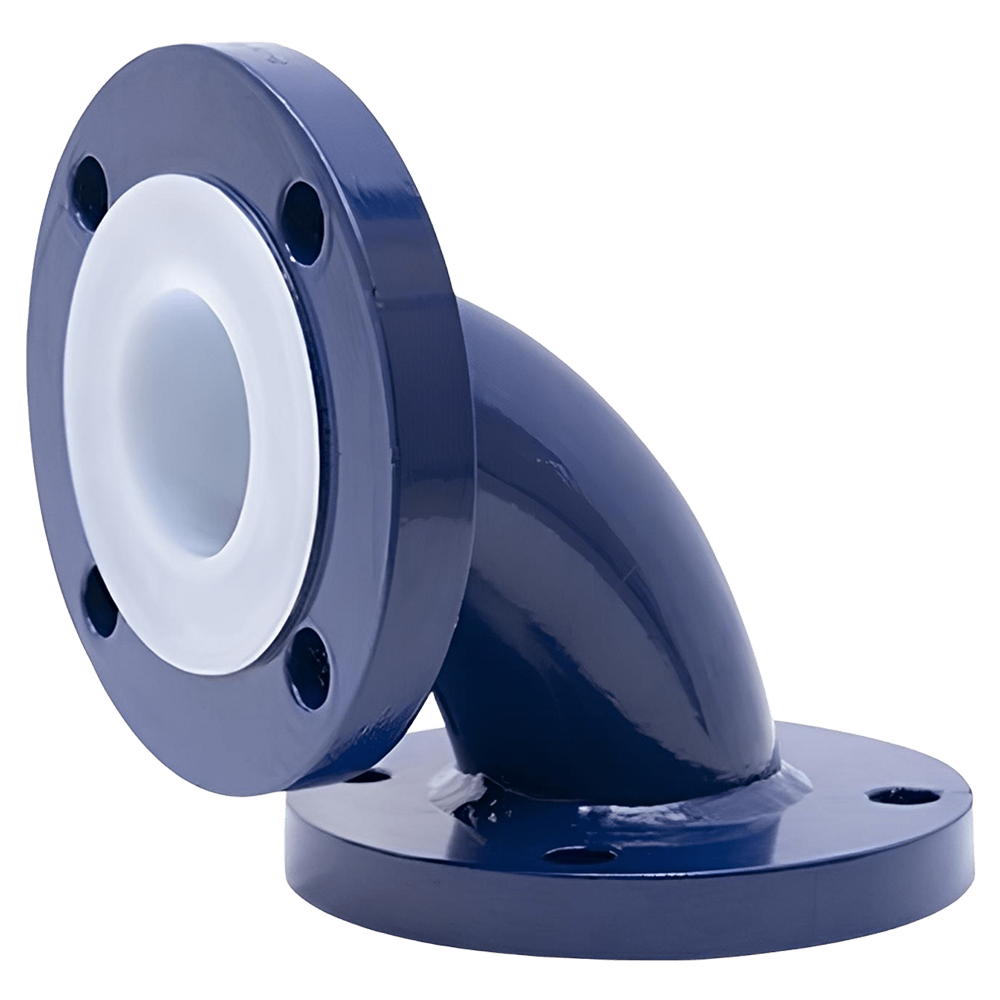

MVS Valves PTFE Lined 90° Elbow is a precision-engineered solution for smooth directional change in highly corrosive process pipelines. Manufactured with a seamless virgin PTFE or PFA liner and housed in a robust ductile iron or carbon steel body, this elbow ensures long-lasting protection against chemical attack, permeation, and corrosion fatigue. It is available in sizes ranging from ½″ to 24″ (DN 15–600), designed to ANSI Class 150/300 or PN 10–25 pressure ratings, and operates efficiently within a broad temperature range of –40 °C to +230 °C. Our PTFE Lined 90 Degree Elbow features raised face flanges and is fully compliant with global piping standards such as ASTM F1545, ASME B16.9, and ISO. All elbows up to 150 mm are provided as cast fittings, while larger sizes are fabricated. The lining is done using paste-extruded PTFE liners that are flared over the flange face to ensure leak-proof sealing. Additionally, FEP and PFA mouldings are standardized for cast elbows to maximize chemical resistance and durability. For sensitive applications, these elbows are also available in anti-static PTFE liners, preventing the build-up of static charges in volatile media handling. Applications of PTFE Lined 90 Degree Elbow This fitting is ideal for use in:

- Chemical and petrochemical process pipelines

- Chlorine and bromine handling systems

- Pharmaceutical and food-grade applications

- Semiconductor and high-purity chemical plants

- Fertilizer and pesticide manufacturing industries

MVS Valves PTFE Lined 45° Elbow is designed for highly corrosive and high-purity fluid transfer systems where a smooth directional change is required. These elbows feature seamless virgin PTFE or PFA liners housed within ductile iron or carbon steel bodies, ensuring excellent corrosion resistance, high durability, and low maintenance. Offered in sizes from ½″ to 24″ (DN 15–600), these elbows meet ANSI Class 150/300 and PN 10–25 standards and are vacuum-rated, making them suitable for both pressure and vacuum service. The product complies with global quality standards such as ASTM F1545, ASME B16.9, and ISO specifications. MVS PTFE Lined 45 Degree Elbow is manufactured via casting up to 150 mm and fabricated for larger sizes. The internal lining is available in FEP, PFA, and PVDF, providing high resistance to permeation and long-lasting performance. The design also includes flat-faced flanges, ideal for bolted flange connections. Key Features

- Full 45° directional bend with corrosion-resistant PTFE lining

- Available in cast (up to 150 mm) and fabricated (above 150 mm) versions

- Wide material selection: PTFE, FEP, PFA, PVDF

- Vacuum-rated and temperature-resistant from –40 °C to +230 °C

- Fully compliant with ASTM, ASME, and ISO standards

- Flanged ends for easy installation and maintenance

- Excellent chemical resistance and anti-stick surface

- Chemical processing industries – For acid, alkali, and solvent pipelines

- Pharmaceutical plants – For clean and contaminant-free flow transfer

- Petrochemical industries – For handling aggressive hydrocarbons

- Pulp & paper plants – For movement of corrosive bleaching agents

- Chlor-alkali units – For brine, chlorine, and caustic media lines

- Fertilizer and acid production – In high-corrosion service line

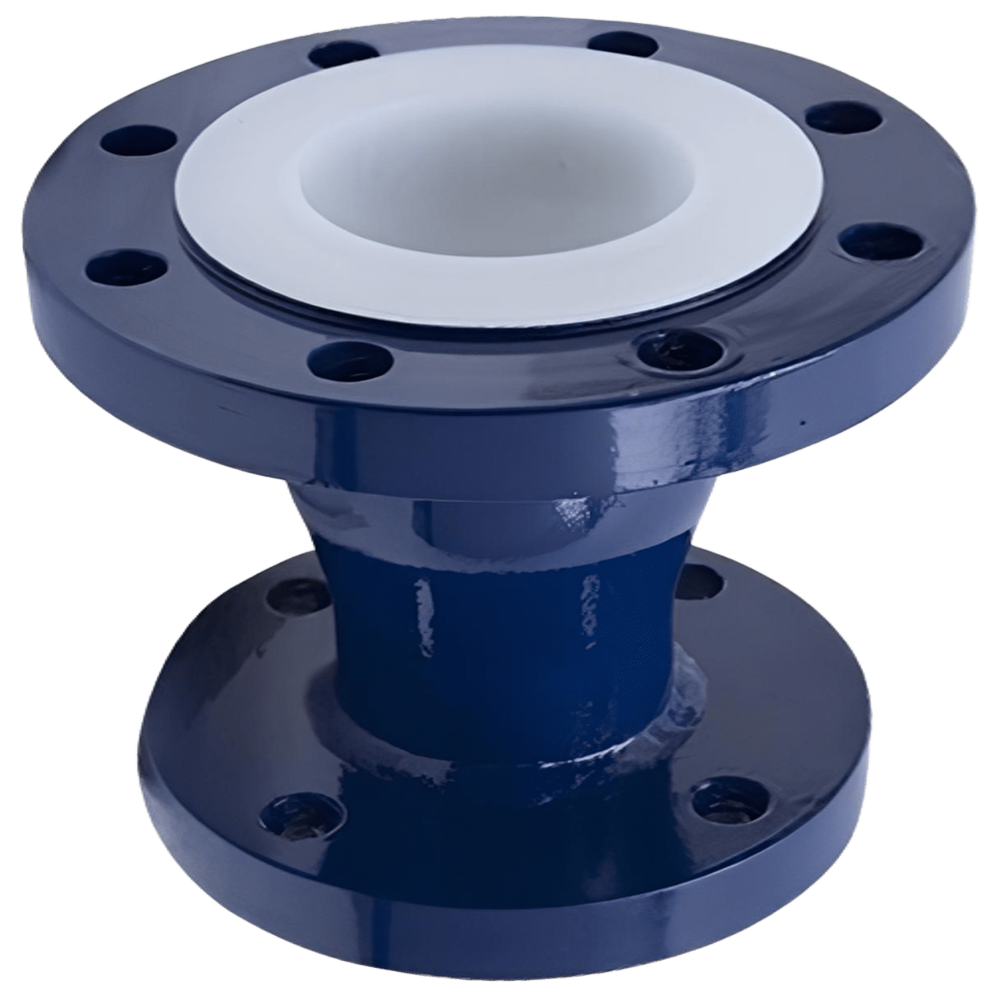

MVS Valves PTFE Lined Concentric Reducers are engineered to ensure safe and smooth transitions between different pipe diameters while maintaining full resistance to corrosive and high-purity process media. These reducers are lined with seamless virgin PTFE or PFA to provide a non-reactive, contamination-free surface inside the pipe, making them ideal for critical applications where chemical compatibility and purity are essential. Built with a strong metallic outer shell using materials like ductile iron, cast steel, or stainless steel, the reducers ensure structural integrity under harsh operating conditions. Designed for use in aggressive environments, the PTFE lining offers exceptional durability and thermal stability, suitable for temperatures ranging from –40 °C to +230 °C. The reducers are manufactured to match ANSI Class 150/300 or PN 10–25 pressure ratings and conform to globally recognized standards such as ASTM F1545, ASME B16.9, and relevant ISO specifications.

Each PTFE Lined Concentric Reducer is offered in a variety of lining options such as FEP, PFA, PVDF, and PP, allowing clients to choose the right solution for their specific media and process requirements. These reducers are fully vacuum-rated and perform excellently in chemical plants, pharmaceutical processing, petrochemical units, water treatment systems, and industries where fluid handling involves highly corrosive acids, solvents, or alkalis. With advanced lining technology and high-quality fabrication, MVS ensures that every PTFE lined reducer delivers long-term reliability, leak resistance, and minimal maintenance even under the most challenging service conditions.

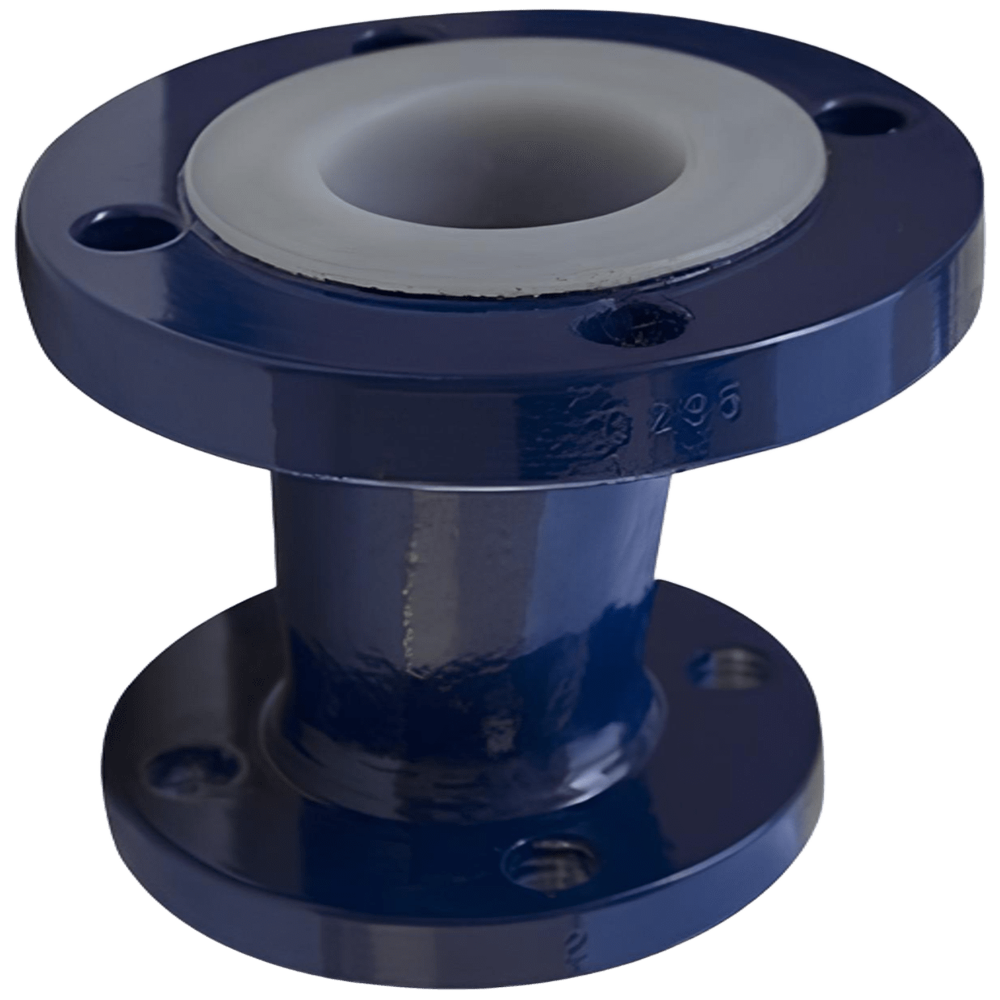

MVS Valves PTFE Lined Eccentric Reducers are engineered to deliver reliable and smooth transitions between pipes of different diameters, especially in horizontal pipework where drainage is essential. These reducers feature an offset centerline that enables proper flow direction while preventing the accumulation of corrosive or hazardous fluids. With a seamless internal lining of high-purity PTFE or PFA, they provide excellent chemical resistance, making sure long-term protection against aggressive acids, solvents, and high-purity media. Manufactured in strong materials such as ductile iron, cast steel, and stainless steel, these reducers combine mechanical strength with corrosion protection. The internal lining is available in PFA, FEP, PVDF, and PP, making them suitable for a wide range of industrial applications including chemical processing, pharmaceuticals, water treatment, and petrochemical installations. Available in sizes from ½″ to 24″ (DN 15–600), and pressure ratings of ANSI Class 150/300 or PN 10–25, they support operation in demanding environments with temperatures ranging from –40 °C to +230 °C.

Each PTFE Lined Eccentric Reducer is designed to conform to ASTM F1545, ASME B16.9, and ISO standards, ensuring consistent quality and safety. The reducers are vacuum-rated and can be supplied with virgin unpigmented liners for high-purity applications or anti-static liners to eliminate the risk of static discharge in volatile media systems. The flanged end connections comply with ASME B16.5 Class 150 and DIN dimensions, offering seamless integration into existing pipelines. Whether used in corrosive chemical lines or critical process systems, MVS PTFE Lined Eccentric Reducers ensure a leak-free, durable, and low-maintenance solution for smooth flow transitions and pipeline integrity.

MVS Valves PTFE Lined Equal Cross is engineered to provide efficient four-way flow distribution in highly corrosive and high-purity piping systems. These fittings are internally lined with premium-grade PTFE or PFA, ensuring exceptional resistance to a wide range of aggressive chemicals and solvents. Designed for long-term performance in demanding industrial applications, they offer a leak-proof, maintenance-free solution in both vacuum and pressure-rated systems. Manufactured using ductile iron, cast steel, or stainless steel, and available with PFA, FEP, PVDF, or PP linings, these crosses are built to handle critical process conditions without compromising structural strength. They are suitable for use in chemical plants, pharmaceutical industries, petrochemical pipelines, and acid handling systems, where precise multi-directional flow control is essential. With a standard size range of ½″ to 24″ (DN 15–600) and pressure ratings up to ANSI Class 150/300 or PN 10–25, these fittings can operate at temperatures between –40 °C and +230 °C.

Each PTFE Lined Equal Cross conforms to ASTM F1545, ASME B16.9, and ISO standards, ensuring high mechanical integrity, dimensional consistency, and global compatibility. These fittings are available with flanged end connections as per ASME B16.5 Class 150 or DIN standards, making them easy to install into new or existing lined piping systems. They can also be supplied with virgin unpigmented liners for ultra-pure media or anti-static liners for volatile applications to prevent electrostatic discharge. Whether used for distributing aggressive fluids or controlling flow across multiple process branches, MVS PTFE Lined Equal Cross fittings offer a safe, durable, and highly chemical-resistant solution for complex industrial piping networks.

PTFE Lined Unequal Cross fittings by MVS Valves are specifically engineered to handle aggressive chemicals and high-purity fluids with unmatched reliability and structural strength. These fittings offer a dependable solution for multi-directional flow control where the outlet dimensions differ from the main line, making them ideal for complex piping systems. Designed to ensure leak-free service, each unit features a high-performance PTFE or PFA lining that resists corrosive attack while maintaining high mechanical stability across varying pressures and temperatures. These unequal crosses are available in sizes ranging from ½″ to 24″ (DN 15–600) and are pressure-rated to ANSI Class 150/300 or PN 10–25. Capable of operating between –40 °C and +230 °C, they are fully vacuum-rated and meet all relevant global standards including ASTM F1545, ASME B16.9, and ISO specifications.

MVS Valves manufactures the PTFE Lined Unequal Cross in robust materials such as ductile iron, cast steel, and stainless steel castings up to 150 NB. For larger sizes, fabricated versions are provided to ensure dimensional integrity and customized compatibility. Customers can request versions with one or two reduced bore branches depending on the application’s flow requirement. We also offer PFA lined reducing crosses with either virgin liner for ultra-clean environments or anti-static liners to prevent static buildup, especially in volatile process lines. As a trusted PTFE Lined Unequal Cross Manufacturer, MVS Valves ensures every component is built with precision and durability to withstand the toughest industrial environments.

As a trusted PTFE Lined Equal Tee Manufacturer, MVS Valves offers high-integrity three-way fittings specially engineered for handling corrosive, toxic, or high-purity media. These tees are internally lined with PTFE or PFA, offering superior chemical resistance and long-term reliability in demanding flow applications. Whether installed in pharmaceutical, petrochemical, or acid transfer systems, our equal tees provide a secure and leak-proof flow path with minimal maintenance. Available in standard sizes ranging from ½″ to 24″ (DN 15–600), our PTFE Lined Equal Tees are vacuum-rated and pressure-tested for ANSI Class 150/300 or PN 10–25 operations. With a working temperature range of –40 °C to +230 °C, they perform reliably even under thermal stress and vacuum conditions. Each tee is manufactured in accordance with ASTM F1545, ASME B16.9, and ISO standards, making sure dimensional accuracy and mechanical durability. To suit varying industrial requirements, we offer PTFE Lined Equal Tee bodies in cast steel and stainless steel, fully lined with FEP, PFA, PVDF, or PTFE. While most standard sizes are produced with cast bodies and rotating flanges, larger sizes or custom configurations are fabricated to meet unique pipeline demands. We also provide static-dissipating (anti-static) liners for explosive or volatile fluid systems, and unpigmented liners for ultra-pure chemical flows.

These tees are commonly used in chemical processing plants, chlor-alkali units, acid manufacturing, pharma-grade fluid systems, and semiconductor fluid handling, where cleanliness, compatibility, and corrosion resistance are essential. If you're seeking a reliable and high-quality PTFE Lined Equal Tee Manufacturer, MVS Valves offers the precise combination of engineering expertise and material excellence your process demands.

PTFE Lined Instrument Tee by MVS Valves is designed to provide accurate, safe, and leak-proof access for measurement, sampling, or instrumentation integration in aggressive chemical or hygienic fluid systems. Engineered with a full internal PTFE or PFA lining, it ensures complete corrosion resistance and process purity, even under harsh operating conditions. These tees are ideal for industries that demand high reliability and clean flow conditions, including pharmaceuticals, chemical processing, and water treatment plants. Available in sizes ranging from ½″ to 1″ (DN 15–25), the PTFE Lined Instrument Tee supports ANSI Class 150 or PN 10–16 pressure ratings and can withstand operating temperatures from –40 °C to +200 °C. Built to meet ASTM F1545, ASME B16.5, and ISO standards, it makes sure vacuum compatibility and long-term mechanical integrity. The reduced branch bore is a design feature that allows it to fit securely between existing pipeline flanges without requiring extensive modifications.

MVS manufactures this tee in both carbon steel and stainless steel variants, using either casting or fabrication methods. Wafer-style models are available for space-constrained installations, offering a compact alternative to traditional full-bodied tees. Whether fabricated from solid MS or SS round bars, each product is crafted with precision and tailored for durability. As a leading PTFE Lined Instrument Tee Manufacturer, MVS Valves delivers dependable solutions tailored to critical process requirements with a focus on quality, compatibility, and operational safety.

As a leading PTFE Lined Reducing Tee Manufacturer, MVS Valves delivers precision-engineered fittings designed for safe and efficient flow distribution across pipelines handling corrosive, toxic, or high-purity media. Our PTFE-Lined Reducing Tees provide optimal flow control where inlet and outlet diameters differ—without compromising on mechanical integrity or corrosion resistance. Each reducing tee is constructed with a durable cast steel or stainless steel body, internally lined with high-grade PTFE or PFA fluoropolymer to ensure maximum chemical compatibility. Designed for aggressive media such as strong acids, alkalis, solvents, and chlorinated compounds, these fittings can handle service temperatures ranging from –40 °C to +230 °C, and are vacuum-capable.

Available in sizes from ½″ to 24″ (DN 15–600) and rated for ANSI Class 150/300 or PN 10–25 pressure systems, these tees comply with global standards including ASTM F1545, ASME B16.9, and ISO. All wetted surfaces are formed from heavy-wall transfer-moulded PTFE or PFA, offering superior resistance to permeation and wear, even under continuous use in challenging chemical environments. At MVS, our PTFE Lined Reducing Tees are typically supplied with investment cast steel bodies as standard. For customized configurations—such as rotating flanges or special dimensional requests—we provide fabricated solutions tailored to your application requirements. Our manufacturing scope also includes PVDF, FEP, and PP linings, extending the versatility of our tee fittings. Whether you operate in pharmaceuticals, petrochemicals, fertilizers, or water treatment, MVS offers high-integrity lined fittings engineered to perform with confidence in the most demanding process conditions.

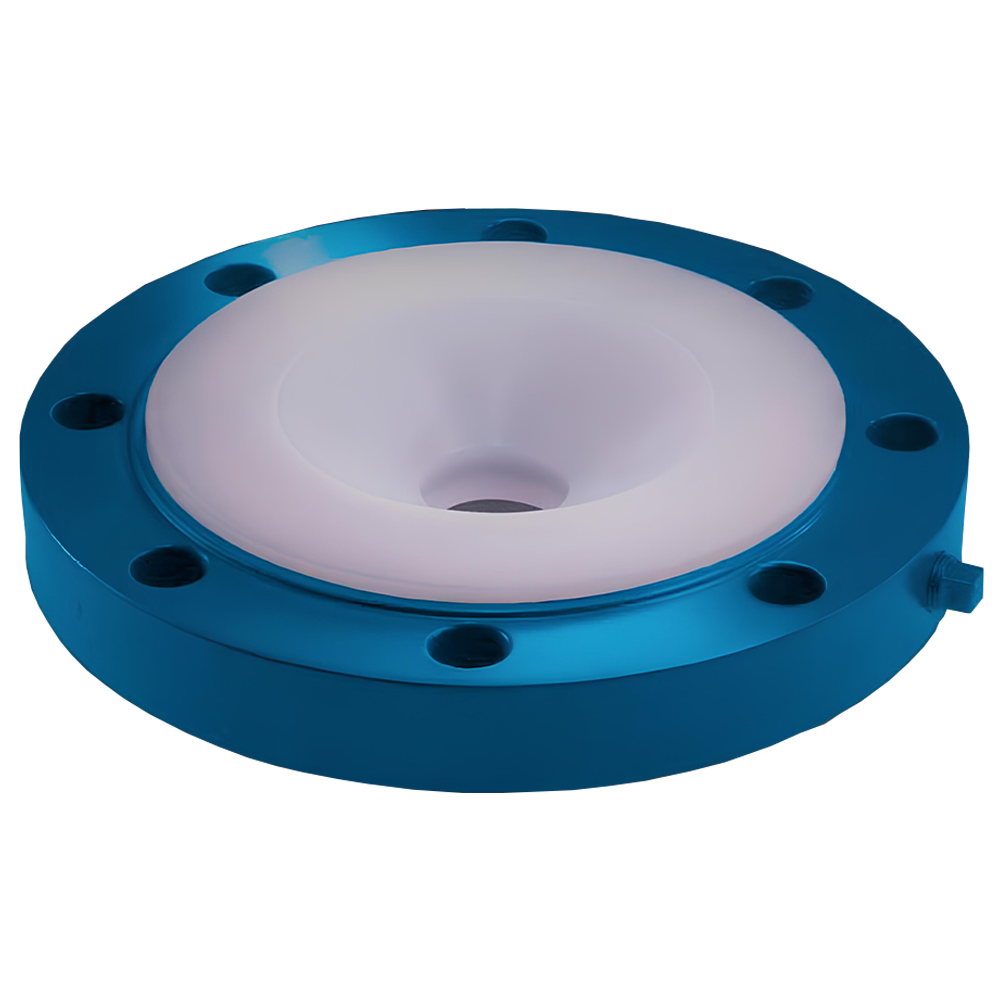

As a reliable PTFE Lined Reducing Flanges Manufacturer, MVS Valves delivers high-performance flange solutions specifically engineered for corrosive, abrasive, or ultrapure applications. Our PTFE-Lined Reducing Flanges allow for smooth transitions between different pipeline diameters while maintaining full corrosion protection and secure sealing. These reducing flanges are available in sizes ranging from ½″ to 24″ (DN 15–600) and pressure-rated for ANSI Class 150/300 or PN 10–25 systems. Designed to withstand challenging conditions, they operate reliably in temperatures between –40 °C and +230 °C, making them suitable for chemical processing, acid transfer, pharmaceutical production, and other demanding environments. All components are manufactured to ASTM F1545, ASME B16.5, and ISO standards, ensuring global quality compliance.

MVS manufactures PTFE Lined Reducing Flanges in a wafer-style design with threaded bolt holes and concentric bores. These flanges feature full PTFE or PFA lining, ensuring excellent chemical resistance and a leak-proof, bubble-tight connection. The lining extends seamlessly into the bore, safeguarding the transition point from corrosion and contamination. We offer both standard reducing flanges, which are readily available in stock, and custom-engineered variants tailored to specific customer specifications. Whether you're handling hydrochloric acid, nitric acid, caustic soda, or any other aggressive media, our lined reducing flanges provide the long-lasting performance and reliability your process demands. When you need a secure and corrosion-proof solution for connecting pipelines of different sizes, trust MVS Valves—the trusted name in PTFE Lined Reducing Flanges Manufacturing.