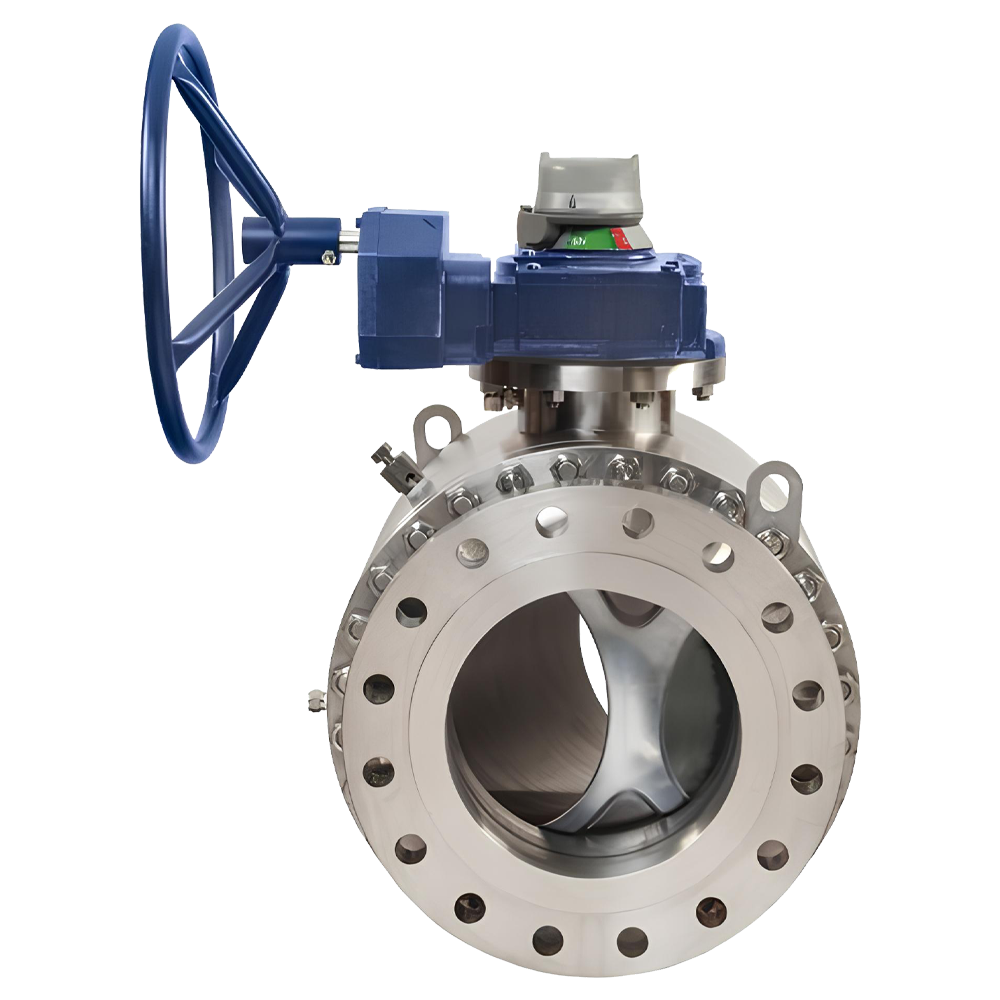

Trunnion Ball Valve

Trunnion Ball Valve Manufacturer

MVS Valves offers high-performance Trunnion Mounted Ball Valves that are designed to deliver superior sealing and reliable operation in high-pressure and large-diameter flow control systems. Built to comply with API 6D standards, these valves are available in both Full Port and Reduced Port designs with Flanged or Butt Weld end connections. The design incorporates key features such as an anti-blowout stem, fire-safe construction, and double block and bleed capability, ensuring optimal safety, minimal leakage, and operational integrity even under extreme pressure and temperature conditions.

To meet the specific requirements of demanding industrial applications, MVS manufactures a wide range of configurations including Cast Steel Full Port Reduced Port Three Piece Trunnion Mounted Ball Valve Flanged Class 300, Class 600, Class 1500, and Class 2500. We also offer Cast Steel Full Port Reduced Port Two Piece Trunnion Mounted Ball Valve Flanged Class 300, Class 600, Class 1500, and Class 2500, tailored to handle various pipeline needs in industries such as oil & gas, petrochemicals, refineries, and power generation.

These trunnion ball valves are engineered with precision to ensure low operating torque, smooth actuation, and long-term durability. They are compatible with manual operation, as well as pneumatic or electric actuators, offering flexible control solutions across different flow media. With robust construction and advanced sealing technology, the MVS Trunnion Ball Valve range provides dependable shutoff and extended service life, even in the most critical flow conditions.

Specification

| Specification | Details |

|---|---|

| Design Standard | API 6D |

| Testing Standard | API 598 / API 6D |

| Face to Face | ASME B16.10 |

| End Connections | ASME B16.5 (Flanged), ASME B16.25 |

| Fire Safe Design | API 607 / API 6FA |

| Size Range | 2″ to 24″ (Larger on Request) |

| Pressure Class | 150# to 2500# |

| Operation | Manual / Gear / Pneumatic / Electric Actuator |

Material of Construction

| Body & Closure | ASTM A105, A350 LF2, A182 F304 / F316, A352 LCB, A216 WCB |

| Ball | ASTM A182 F316 / F304 / F51, ENP Coated, Hardfaced |

| Stem | A182 F6a / F304 / F316 / Monel |

| Seat Insert | PTFE, RTFE, Devlon, Nylon, PEEK, Metal |

| Seals & Gaskets | PTFE, Graphite, Spiral Wound |

| Fasteners | ASTM A193 B7 / B8M, A194 2H / 8M |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

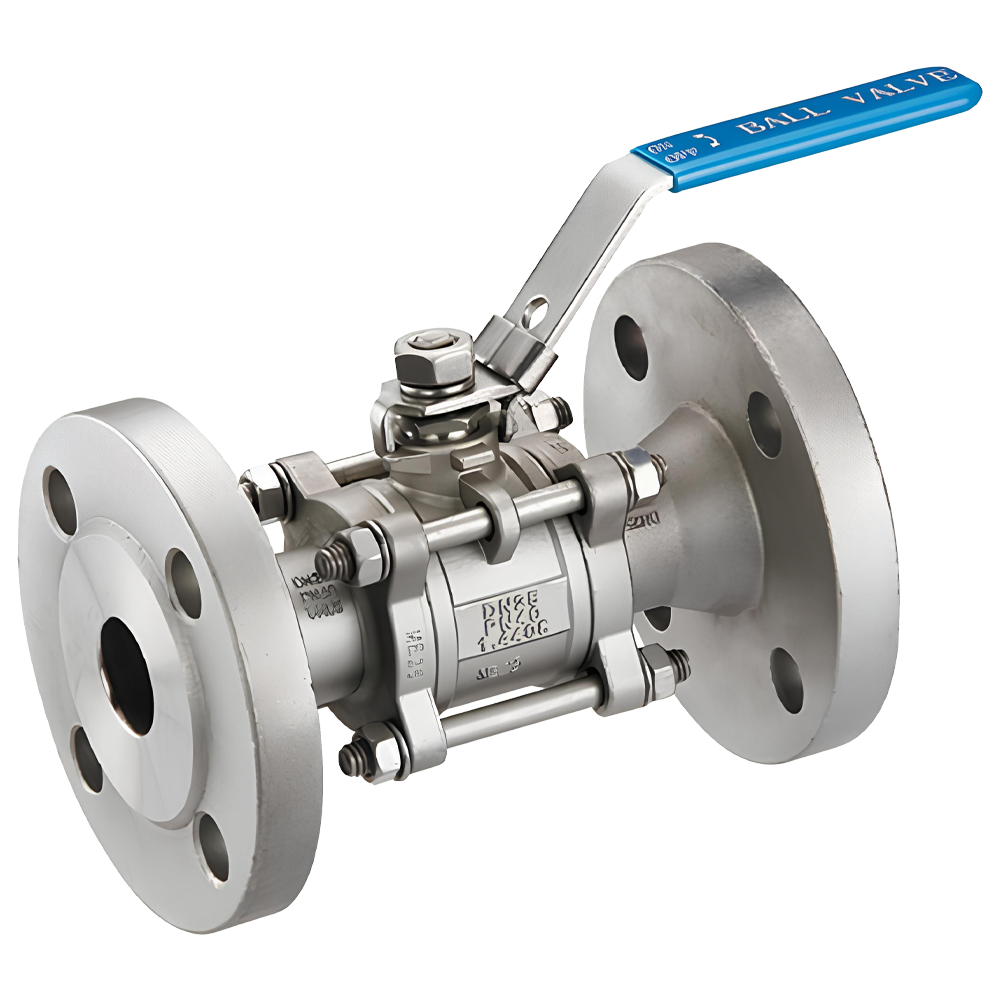

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia