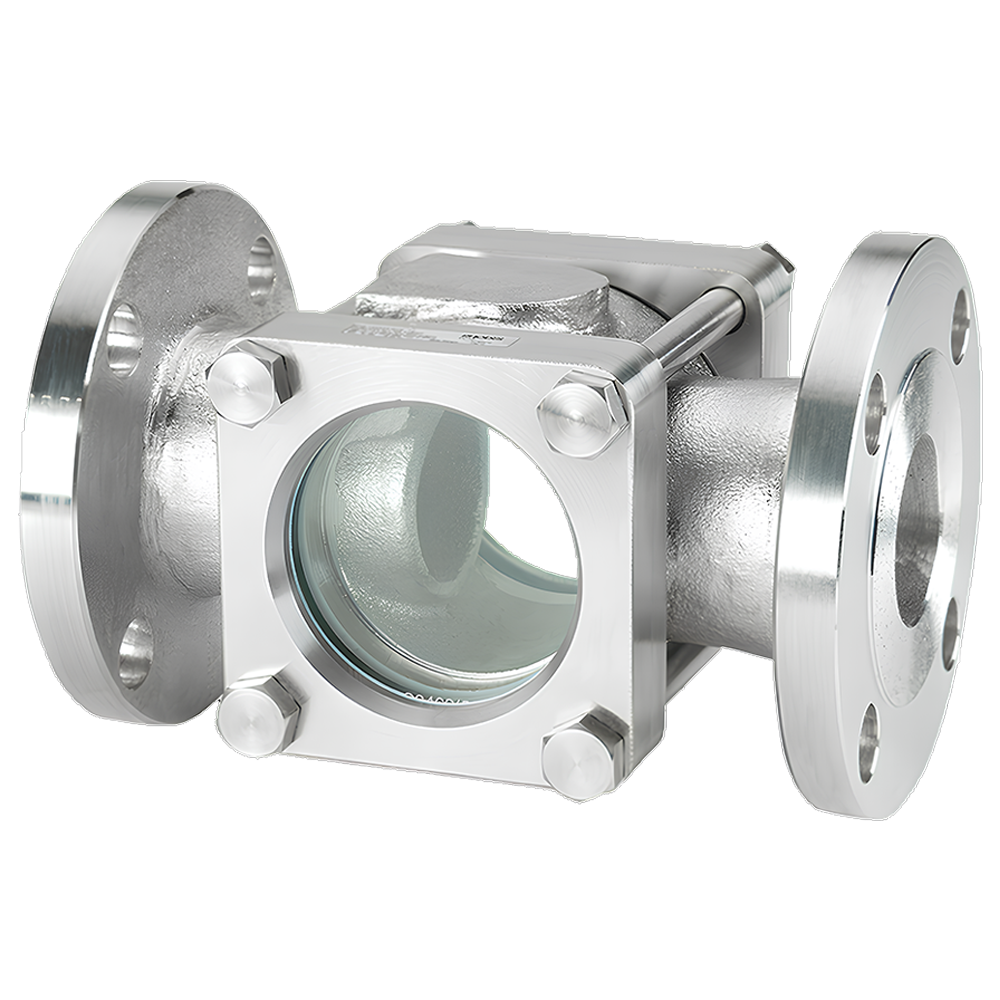

Double Window Sight Glass

Double Window Sight Glass Manufacturer

MVS Valves Double Window Sight Glass is a precision-engineered viewing device designed to offer continuous and reliable visual monitoring of process media in critical pipeline systems. This flow indicator consists of two thick borosilicate glass panes mounted on opposite sides of a cast or fabricated body, ensuring enhanced visibility and added safety. The rugged construction makes it ideal for industrial applications where clear observation is required under high pressure and elevated temperature conditions. Whether inspecting the color, clarity, or movement of a fluid, this sight glass enables accurate, real-time process checks without interrupting operations.

Manufactured using top-grade materials such as Cast Carbon Steel Double Window Sight Glass and duplex stainless steel variants, this product is well-suited for corrosive and demanding environments. The integration of PTFE-sealed gaskets and optional PTFE-lined Double Window Sight Glass configurations makes it particularly effective for chemical, pharmaceutical, and steam service applications where non-contamination and chemical resistance are essential. With support for pressure ratings up to 20 bar and temperature limits of up to 200 °C, it performs with dependable clarity and durability. The double-pane design also offers a built-in safety feature—ensuring uninterrupted visual access even if one glass layer cracks. Whether specified as a Double-window flow sight glass or a Duplex Double Window Sight Glass, this component remains a trusted choice for operators requiring visual flow assurance in harsh or sensitive pipeline conditions.

Specification

| Specification | Details |

|---|---|

| Valve Type | Double-window flow sight glass |

| Size Range | DN 25–DN 200 (1″– 8″) |

| Pressure Rating | ANSI 150#, ANSI 300# |

| Temperature Range | –20 °C to +200 °C (borosilicate); up to +280 °C with quartz/ mica shield |

| Glass Type | Borosilicate (DIN 7080); quartz optional |

| Face-to-Face / Flange | ANSI flanged, As per Manufacturer Standard |

| Connection | Flanged |

| Testing | Pressure tested to API 598 / EN 12266‑1 |

| Service Media | Water, steam, chemicals, oils; for steam trap monitoring |

Material of Construction

| Body & Flanges | Carbon Steel (WCB), 304/316 SS | CF8M, Duplex, Hastelloy, PTFE-lined |

| Glass Pane | Borosilicate DIN 7080 | Quartz, soda-lime, sapphire, mica-shielded |

| Gaskets | PTFE, NBR, EPDM | Graphite, FKM, mica-composite |

| Tie Rods/Nuts | 304 SS rods, 304/316 nuts | 316L or alloyed SS |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia