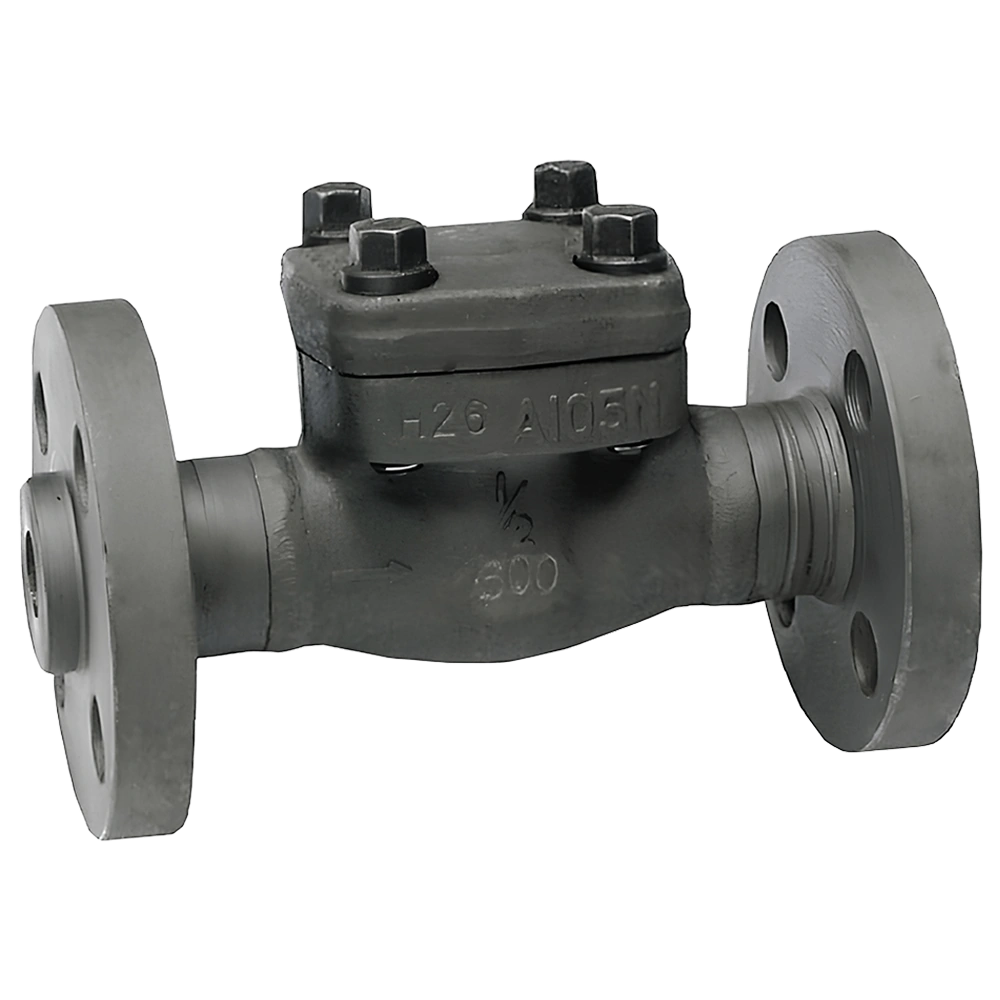

Forged Steel Check Valve

Forged Steel Check Valve Manufacturer

MVS Valves manufactures robust Forged Steel Check Valves designed to deliver consistent, one-directional flow in high-pressure gas, oil, and water pipeline systems. These valves are engineered with heavy-duty forged steel construction using premium materials such as ASTM A105, F304L, F316L, and special alloys including Inconel, Monel, and Alloy 20. Offering superior strength, compact body profiles, and leak-tight shutoff, our check valves are an ideal solution for demanding flow control environments across industries.

Every Forged Steel Piston Lift Check Valve is crafted to meet rigorous international standards such as API 602, ASME B16.34, and BS 5352, making sure long-term performance and corrosion resistance under elevated temperatures and pressures. Available in various configurations such as Threaded, Socket Weld, Butt Weld, and Flanged Ends, these valves cater to Class ratings ranging from 150 to 2500. MVS also supplies API 602 A105 LF2 Forged Carbon Steel Check Valve Class 800 Socket Weld Ends, perfectly suited for high-pressure applications in refineries and chemical processing systems.

Our horizontal piston type forged steel check valve incorporates a bolted cover design that guarantees mechanical integrity during sudden pressure surges. We also offer Forged Non Return Valve options with Lift or Piston-Lift mechanisms, including Forged Steel Piston Lift Check Valve Rating Class 800 Threaded/Socket Weld Ends and Forged Steel Piston Lift Check Valve Rating Class 1500 Threaded/Socket Weld Ends, each providing reliable non-slam flow control with minimal maintenance.

MVS’s product lineup includes highly corrosion-resistant variants such as API 602 F304L Forged Stainless Steel Check Valve Class 800 Threaded Ends and API 602 F316L Forged Stainless Steel Check Valve Class 800 Butt Weld Ends, which are widely used in power plants and marine applications. Additionally, the company produces high-performance API 602 F5 F9 F11 F22 F91 Forged Alloy Steel Check Valves Class 800 Screwed Ends, which ensure chemical resistance and thermal stability.

For critical flow lines, MVS supplies precision-built API 602 F51 Forged Duplex Steel Check Valve Class 150 Flanged Ends, API 602 F53 Forged Duplex Steel Check Valve Class 300 Flanged Ends, and API 602 F55 Forged Duplex Steel Check Valve Class 600 Flanged Ends, offering unmatched mechanical strength and excellent crack resistance. In aggressive environments, users rely on API 602 Inconel 625 Forged Check Valves Class 1500 Flanged Ends and API 602 Monel K400 Forged Check Valve Class 2500 Flanged Ends for extreme temperature and pressure control.

Whether it’s a Forged Steel Piston Lift Check Valve Rating Class 150/300/600 Flanged Ends or a Forged Non Return Valve customized for your flow system, MVS ensures precision machining, zero leakage, and easy maintenance, making these valves a durable and high-performance choice for continuous operation in critical applications.

Specification

| Specification | Details |

|---|---|

| Valve Style | Forged Steel Check Valve – Lift / Piston Lift |

| Size Range | 15 mm to 50 mm (½″–2″) |

| Pressure Class | Class 800# – 1500# |

| Materials | Forged Steel per ASTM A105, F304L, F316L, F11, F22, LF2, F5, F9, F91 |

| Connection Types | Screwed or Threaded Ends, Socket-Weld, Flanged |

| Operating Media | Gas, Oil, Water, General Industrial |

| Operating Temperature | High – depending on material (e.g., F316L suitability) |

| Standards Compliance | API, ASME, ISO 9001 certified |

| Testing | API/ASME pressure testing certified |

Material of Construction

| Body & Bonnet | ASTM A105 (Carbon Steel) | ASTM F304L, F316L (Stainless); F11, F22, F91 (Alloy Steel) |

| Disc / Piston | Forged Carbon Steel | Stainless Steel variants (F304L/F316L) |

| Sealing Seat | Metal-to-metal forged seal | Optional PTFE or soft-seated inserts |

| Spring (if applicable) | 304 SS | Inconel or Monel (for higher temp) |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia