PTFE Lined Pipe

PTFE Lined Pipe Manufacturer

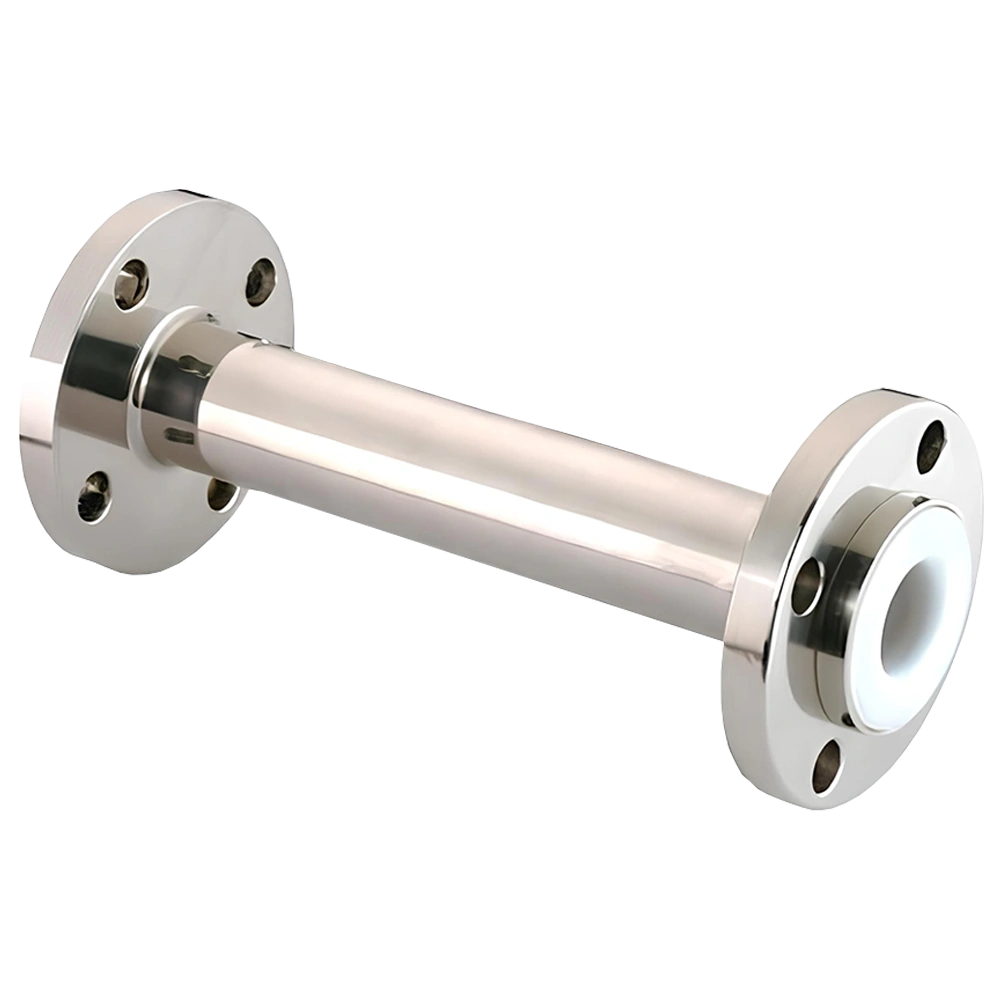

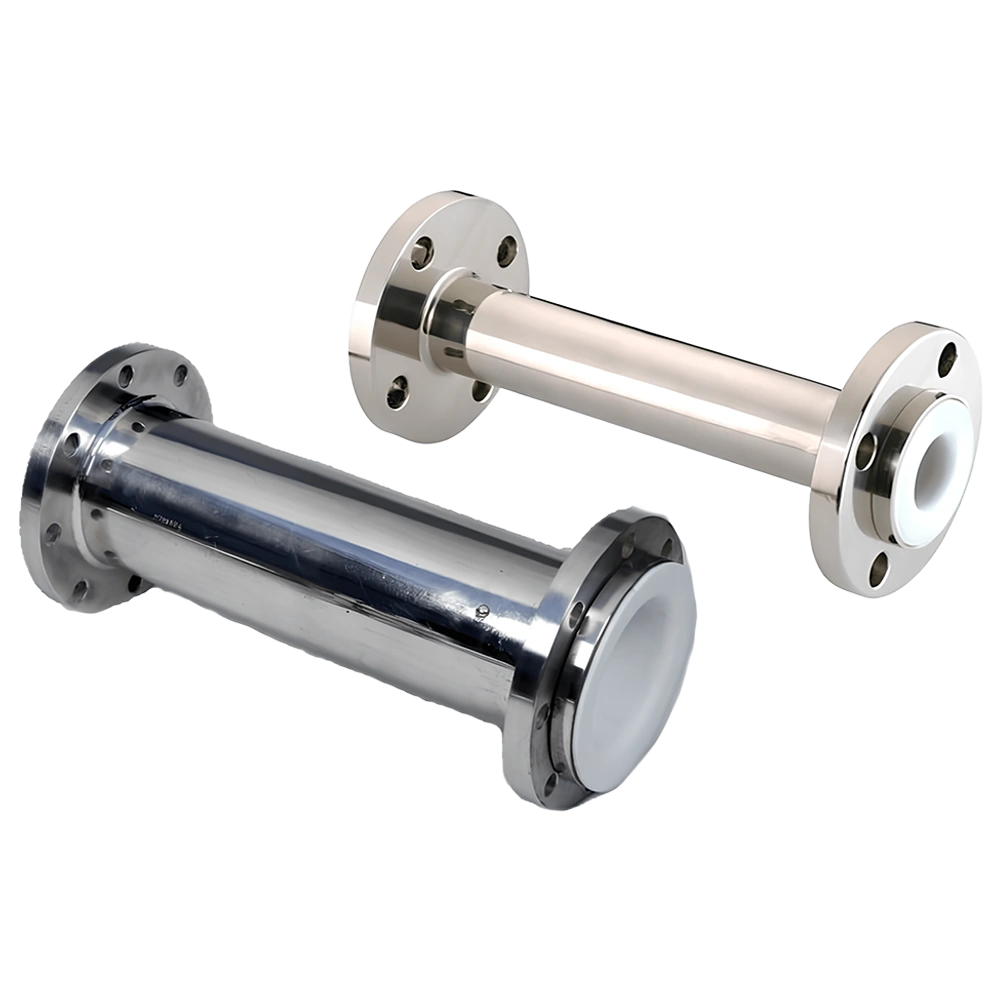

As a trusted PTFE Lined Pipe Manufacturer, MVS Valves offers premium-quality lined pipe systems designed for safe and long-lasting fluid transport in chemically aggressive and high-purity environments. Our PTFE-Lined Pipes combine the chemical inertness of virgin PTFE with the structural integrity of carbon steel or stainless steel, making them ideal for handling acids, alkalis, solvents, and other corrosive fluids.

Manufactured in sizes ranging from ½″ to 24″ (DN 15–600), these pipes are pressure-rated for ANSI Class 150/300 or PN 10–25, and operate reliably in temperatures between –40 °C to +230 °C. Fully compliant with ASTM F1545, ASME B16.5, and ISO standards, our PTFE lined pipes are vacuum-rated and tested to ensure zero leakage and absolute process integrity.

Our PTFE lined pipe systems are engineered using high-grade carbon steel or stainless steel, tailored to the demands of various industries like chemical processing, pharmaceuticals, acid manufacturing, wastewater treatment, and chlor-alkali plants. Each spool is internally lined with seamless, paste-extruded PTFE, offering superior permeation resistance and long service life even under severe operating conditions. Whether you require straight pipe spools or need integration with PTFE-lined fittings, valves, and instrumentation, MVS Valves delivers a comprehensive, high-performance solution that minimizes downtime and maximizes safety. If you’re looking for a reliable, corrosion-proof solution for aggressive fluids, choose MVS Valves—your go-to PTFE Lined Pipe Manufacturer with a proven track record of quality and innovation.

Specification

| Specification | Details |

|---|---|

| Size Range | 25 mm to 300 mm |

| Max Available Length | 3000 mm |

| End Connection | One Flange Fixed and Other Flange Loose, or Both Flanges Fixed |

| Flange Dimensions | DIN PN 10/16, BS 10, ASME 150 / 300, Mixed |

| Lining | PTFE Liner Extruded from PTFE Resin as per ASTM F1545-97 (2003) |

| Lining Options | HDPE, PP, Polypropylene |

| Lining Thickness | Minimum 3.5 mm / 6.0 mm Overall (±1.0 mm Tolerance) |

| Lining Spark Test | 15 KVDC After Lining |

| Hydraulic Test | 20 Kg/cm² After Lining |

Material of Construction

| Pipe Material | Carbon Steel Seamless Pipes conforming to ASTM A106 Gr. B, Sch. 40 Stainless Steel ASTM A312 TP 304 / 316, Sch. 40 |

| Flanges & Collars | IS 2062 Plates, ASTM A105 CF8 (SS 304), CF8M (SS 316) Carbon Steel, Stainless Steel |

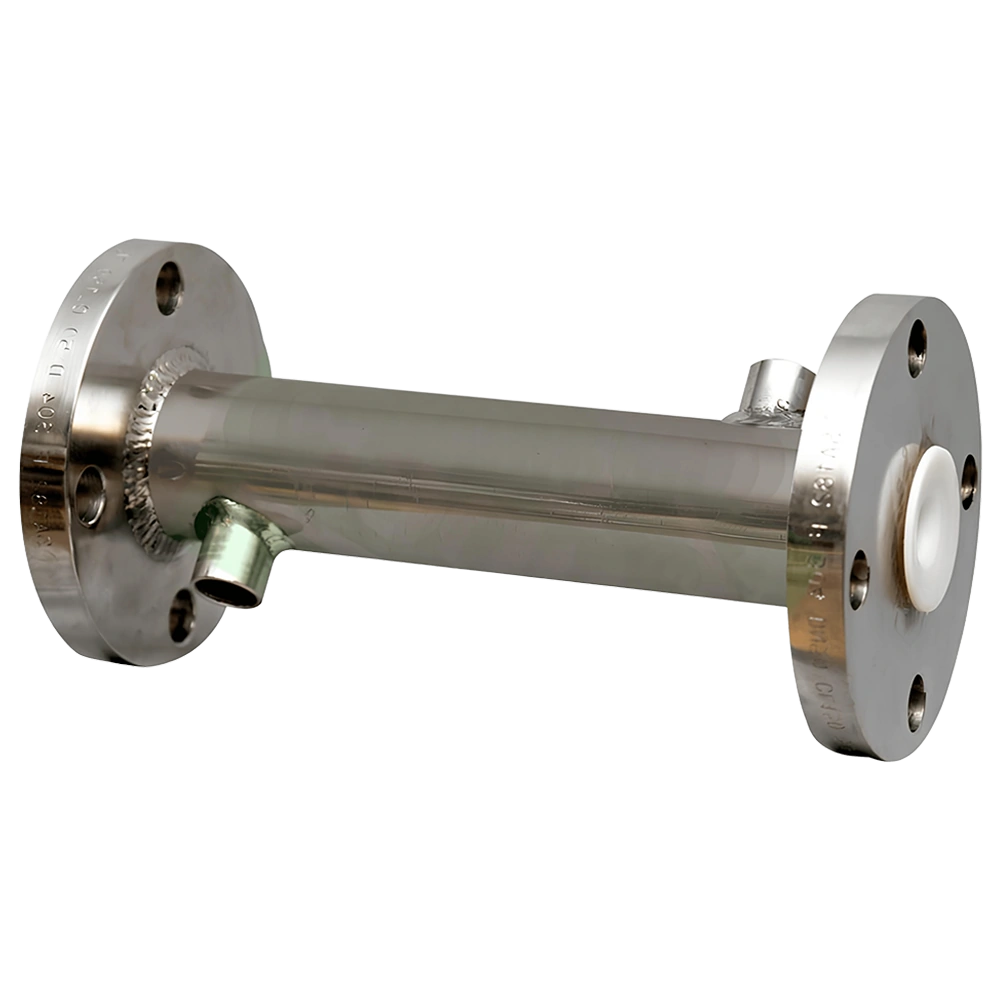

| Vent Extensions | 75 mm Long (Optional, for lagged systems) |

| Venting Details | Required on all lined systems to release permeated gases: Pipes < 500 mm: 2 Central Holes Pipes ≥ 500 mm: 4 Holes (2 at each end) |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia