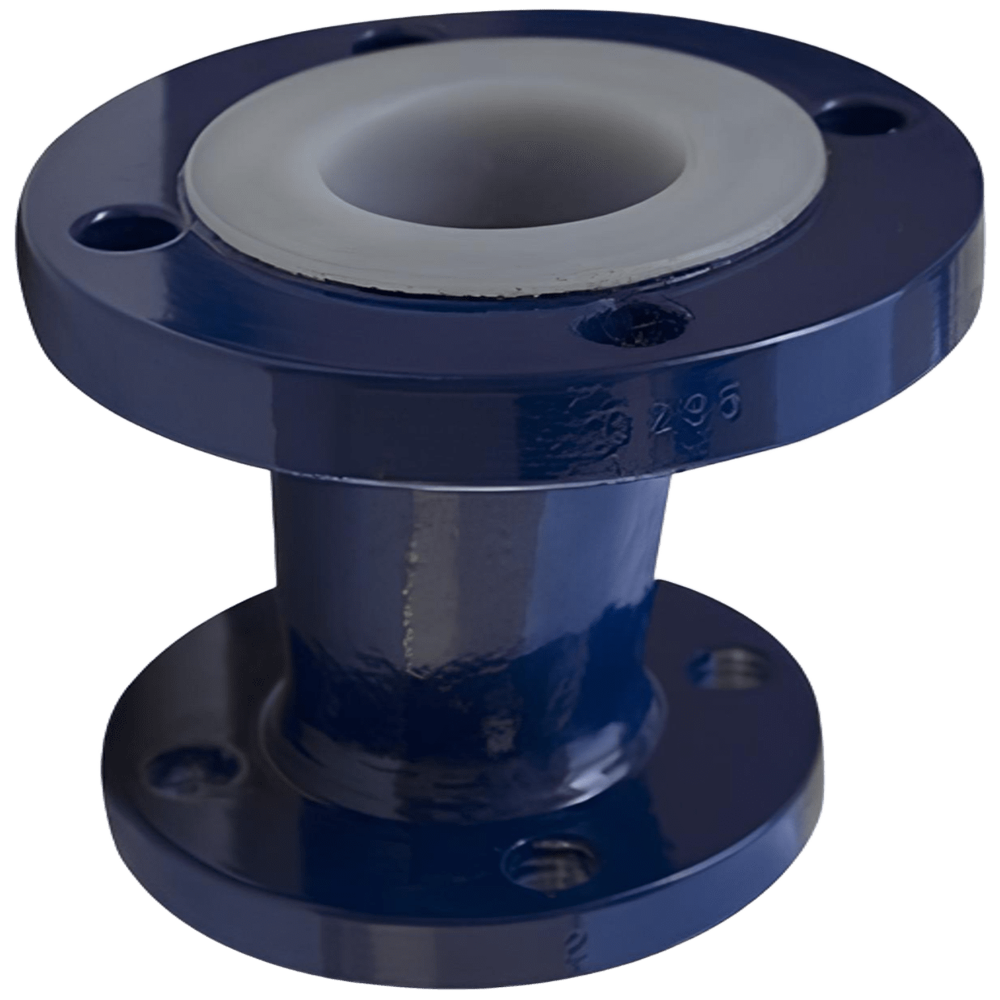

PTFE Lined Reducing Tee

PTFE Lined Reducing Tee Manufacturer

As a leading PTFE Lined Reducing Tee Manufacturer, MVS Valves delivers precision-engineered fittings designed for safe and efficient flow distribution across pipelines handling corrosive, toxic, or high-purity media. Our PTFE-Lined Reducing Tees provide optimal flow control where inlet and outlet diameters differ—without compromising on mechanical integrity or corrosion resistance.

Each reducing tee is constructed with a durable cast steel or stainless steel body, internally lined with high-grade PTFE or PFA fluoropolymer to ensure maximum chemical compatibility. Designed for aggressive media such as strong acids, alkalis, solvents, and chlorinated compounds, these fittings can handle service temperatures ranging from –40 °C to +230 °C, and are vacuum-capable.

Available in sizes from ½″ to 24″ (DN 15–600) and rated for ANSI Class 150/300 or PN 10–25 pressure systems, these tees comply with global standards including ASTM F1545, ASME B16.9, and ISO. All wetted surfaces are formed from heavy-wall transfer-moulded PTFE or PFA, offering superior resistance to permeation and wear, even under continuous use in challenging chemical environments. At MVS, our PTFE Lined Reducing Tees are typically supplied with investment cast steel bodies as standard. For customized configurations—such as rotating flanges or special dimensional requests—we provide fabricated solutions tailored to your application requirements. Our manufacturing scope also includes PVDF, FEP, and PP linings, extending the versatility of our tee fittings. Whether you operate in pharmaceuticals, petrochemicals, fertilizers, or water treatment, MVS offers high-integrity lined fittings engineered to perform with confidence in the most demanding process conditions.

Specification

| Specification | Details |

|---|---|

| Size Range | 25 mm to 200 mm (Larger sizes on request) |

| Type | Unequal or Reducing Tee |

| End Connection | Both Sides Fixed Flanges – Rotating – Fixed On/Off Centres |

| Flange Dimensions | DIN PN10/16, BS 10, ASME 150 / 300, Mixed |

| Lining Material | Moulded FEP, PFA |

| Lining Options | PVDF, PP, HDPE |

| Lining Thickness | Minimum 3.5 mm / 6.0 mm overall (±1.0 mm Tolerance) |

| Lining Spark Test | 20 KVDC After Lining |

| Hydraulic Test | 29 Kg/cm² After Lining |

| Special Geometry | Non-standard dimensions; sizes above 6″ fabricated from SCH 40 pipe |

| Optional Flange Drilling | DIN 2632 / 2633, BS 10 Table D, E, F (on request) |

Material of Construction

| Body Materials | Steel Fabrication – ASTM A234 Gr.WPB Ductile Iron GGG40.3 / ASTM A395 Cast Steel ASTM A216 Gr. WCB Stainless Steel ASTM A312 TP 304 / 316 (SCH-40) |

| Flange Materials | IS 2062 Plates ASTM A105 Stainless Steel CF8 (SS 304) / CF8M (SS 316) |

| Liner Types | Virgin PTFE or Anti-Static (Static Dissipating) PTFE |

| Design Features | One-piece steel construction Wetted parts made from heavy wall transfer moulded fluoropolymer Fabricated for specials and tees with rotating flanges |

| Extras | Earthing Studs / Lugs, Vent Extensions |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia