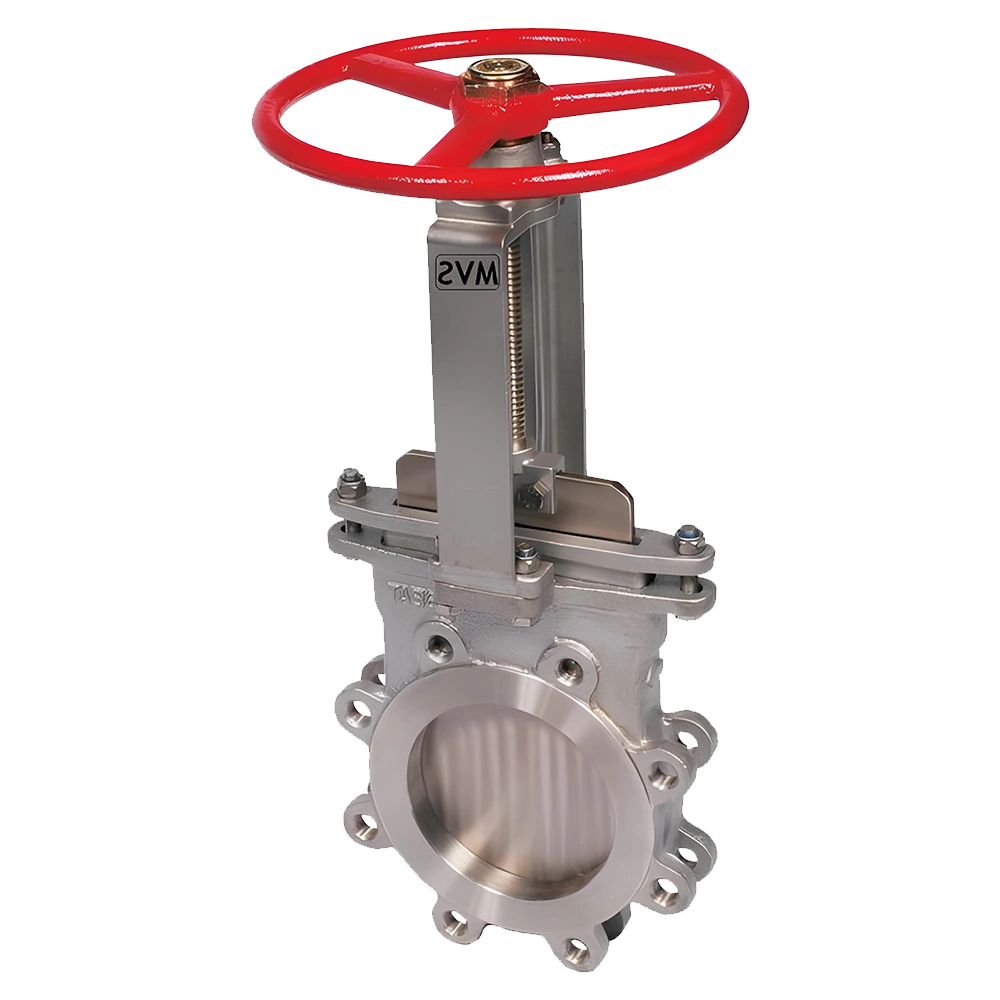

Wafer Butterfly Valve

Wafer Butterfly Valve Manufacturer

MVS Valve’s Wafer Butterfly Valve delivers a sleek, space-saving solution for flow control in tight piping systems. These valves are precision-engineered to API 609 and BS 5155 standards, ensuring reliable performance through sturdy disc construction and smooth stem bearing operation. Adjusted to fit pipelines from DN50 to DN1200 wafer butterfly valve range, they offer consistent shut-off and exceptionally low operating torque, making them ideal for both manual and automated systems.

Constructed with a wafer-style body, this valve is available with either resilient or PTFE-coated wafer butterfly valve seats, providing superior sealing and chemical resistance. For applications requiring higher purity or corrosive media handling, the stainless steel wafer butterfly valve variant ensures durability without compromising flow integrity. The PTFE lining further enhances chemical compatibility, reducing the risk of contamination in sensitive processes.

The API 609 wafer type butterfly valve design accommodates pressures up to PN 16/10 bar and even full vacuum conditions, supporting demanding industrial, water, HVAC, and light chemical applications. Added flexibility comes through ISO 5211 actuation mounting, which allows for seamless integration with manual handles or automated actuators—making this one of the best wafer butterfly valves for process industry use cases.

From its compact wafer-body and rugged seat options to standardized actuation compatibility and compliance with international standards, the MVS Wafer Butterfly Valve is a dependable, high-performance product for industries seeking effective flow control in limited spaces.

Specification

| Specification | Details |

|---|---|

| Valve Type | Concentric wafer-style butterfly valve |

| Pressure Rating | Class 150 (PN 10–16); 2″–12″ rated up to 16 bar, ≥14″ up to 10 bar |

| Size Range | DN 50–DN 1200 (2″–48″) |

| Standards | API 609 / BS 5155; face‑to‑face per ISO 5752/EN 558; tested to API 598, EN 12266‑1, ISO 5208 |

| Shut-Off Class | Class VI bubble-tight when resilient seated |

| Body Type | Wafer design, suitable for bi-directional and vacuum service |

| Torque Reduction | Upper & lower bearings reduce wear, ensure smooth rotation |

| Actuation | ISO 5211 mounting pad—lever, gearbox, pneumatic or electric |

| Operating Media | Water, gas, steam, HVAC fluids, light chemicals |

| Temperature Range | –29 °C to +200 °C (depends on seat material) |

Material of Construction

| Body | Ductile Iron (ASTM A536), Cast Carbon Steel (WCB) | Stainless Steel CF8/CF8M, CF3M, Duplex, Alloy 20, Hastelloy C‑276, Titanium |

| Disc | Ductile Iron (EN‑GJS‑400‑15) or CF8M SS | Aluminum Bronze, PFA/PTFE coated, special alloys |

| Stem | Stainless Steel 416/410/316 | Duplex SS, 17‑4PH, Monel |

| Seat / Liner | EPDM, NBR, Viton | PTFE |

| Bushings & Bearings | PTFE bushings; Acetal or bronze bearings | Graphite, high-temp variants |

| Coatings | Standard epoxy/poly powder on iron bodies | Chemical-resistant linings (e.g. food-grade, potable water) |

Application Industries

Crude Oil & Natural Gas Industry

Chemical & Petrochemical Industry

Water & Wastewater Treatment

Nuclear & Thermal Power Generation

Food & Beverage Industry

Pharmaceutical & Biotechnology

Pulp & Paper Industry

Mining & Mineral Processing

Marine & Shipbuilding

HVAC & Building Services

Automotive & Paint Chemical Manufacturing

Environmental & Bio Gas Renewable Energy

Steel & Metal Processing

Fertilizer Plants, Polymer Production

Cosmetics & Personal Care

Cement & Construction

Chlor-Alkali Industry

Mineral Acids Industry

Related Valves

Exporting Reliable Valve Solutions Across Continents

Australia | Argentina | Austria | Bahrain | Belgium | Bulgaria | Canada | Chile | China | Colombia | Czech Republic | Denmark | Egypt | Finland | France | Germany | Greece | Hong Kong | Hungary | Indonesia | Iran | Ireland | Israel | Italy | Japan | Jordan | Kuwait | Korea | Saudi Arabia (KSA) | Lebanon | Lithuania | Malaysia | Mexico | Netherlands | New Zealand | Nigeria | Norway | Oman | Peru | Philippines | Poland | Portugal | Puerto Rico | Qatar | Romania | Russia | Serbia | South Africa | South Korea | Spain | Sweden | Switzerland | Syria | Taiwan | Thailand | Turkey | Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) | United States of America (USA) | Venezuela | Vietnam | Yemen | Zambia