Valves Manufacturer & Exporter

MVS Valves PVDF Ball Valve is designed to handle the toughest industrial demands where chemical compatibility and long-lasting performance are non-negotiable. This two-way valve features a robust three-piece full bore construction, offering unrestricted flow and low-pressure drop — ideal for process-critical applications. Constructed using corrosion-resistant materials such as isotactic Polypropylene (PP), PPH, PVDF, and HDPE, it is suitable for handling aggressive chemicals like sulphuric acid, hydrochloric acid, chlorine, bromine, and chlorinated paraffin wax. Available with flanged, screwed, or threaded end connections, the PVDF Ball Valve ensures easy integration into new or existing pipeline systems. The PVDF Ball Valve with flanged ends is widely preferred for fixed installations, while the screwed or threaded end options provide flexibility in compact or modular systems. MVS also offers corrosion resistant plastic manual ball valves and corrosion resistant plastic pneumatic ball valves, giving customers the choice between manual and automated flow control based on their process needs. For automation, the Automatic PVDF Ball Valve with pneumatic actuator delivers efficient and precise control in continuous operation environments. The internal ball, fully encapsulated in PVDF, ensures excellent chemical resistance, making it an ideal solution for chlor alkali industries and for handling Sodium Hypochlorite or Sulphuric Acid with safety and reliability. We are a trusted PPH Body PVDF Lined Ball Valve manufacturer, offering products that combine structural strength with chemical durability. Our Isotactic PP Ball Valve with PVDF ball is widely used in industries where purity and resistance to harsh chemicals are essential, such as pharmaceuticals, food processing, and chemical manufacturing. Whether you're operating in the chlor-alkali sector or managing highly reactive chemical processes, MVS PVDF Ball Valves deliver unmatched reliability, leak-free sealing, and extended service life even in the most corrosive environments.

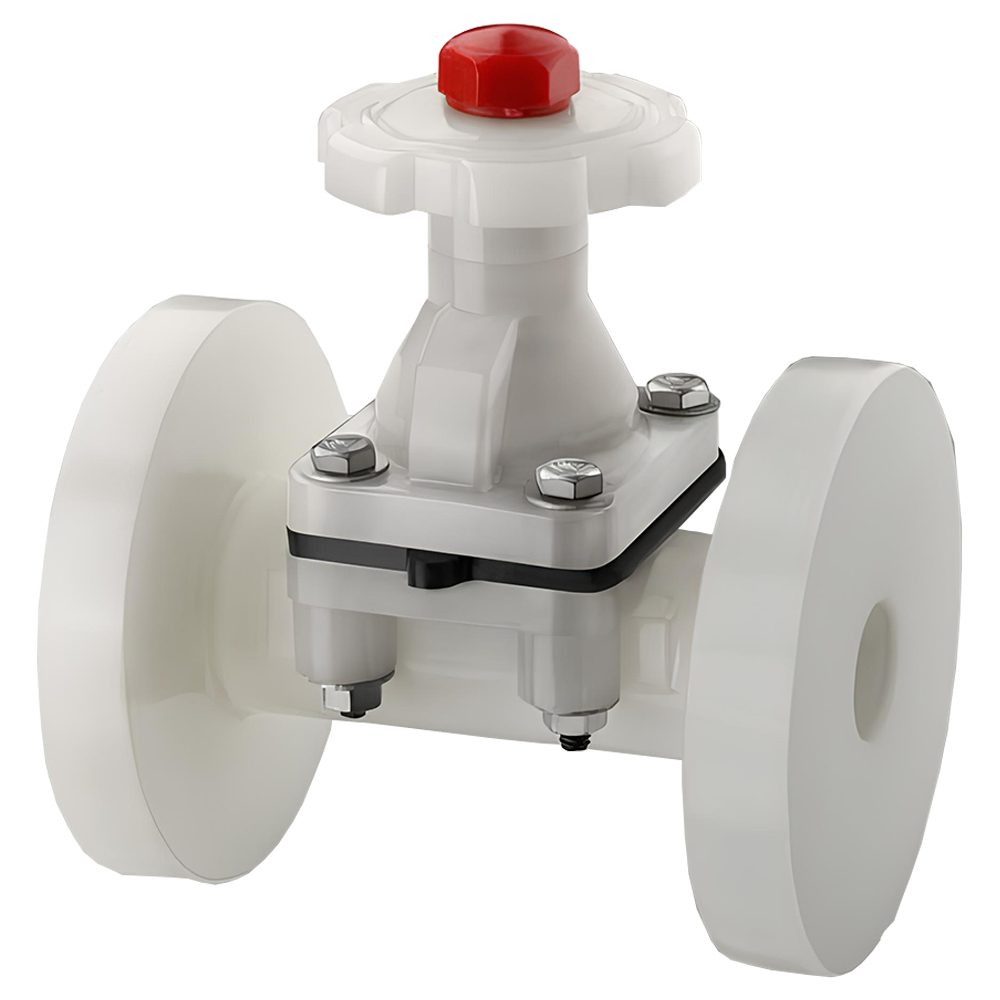

The MVS PVDF Diaphragm Valve is engineered for high-efficiency flow control in highly corrosive and chemically demanding environments. Designed with precision and built using PVDF (Polyvinylidene Fluoride) and Isotactic Polypropylene (PP), this two-way valve offers exceptional corrosion resistance, long-term durability, and smooth performance in both throttling and shut-off applications. Available in sizes ranging from 15 mm to 150 mm, the valve is manufactured to handle diverse industrial media with ease. Its robust thermoplastic body construction is supported by a wide selection of elastomer diaphragm materials, making it adaptable to many operational conditions and process requirements. Whether your application demands a sulphuric acid resistant diaphragm valve or solutions compatible with bromine, hydrochloric acid, or chlorinated fluids, MVS delivers unmatched reliability. Built to serve critical operations, our corrosion resistant PVDF diaphragm valves are ideal for use in chlor alkali processing, bromine handling, and other aggressive chemical applications. For processes involving sulfuric acid, these valves ensure safe and leak-free operation, while resisting wear from abrasion and scaling over time. As a PP diaphragm valve manufacturer and PPH diaphragm valve supplier, MVS brings precision engineering and global supply capability under one trusted brand. Our acid resistant thermoplastic diaphragm valves combine the mechanical strength of polypropylene-based bodies with the chemical shielding of PVDF, creating a valve suitable for a wide variety of harsh environments. MVS also serves as a trusted PVDF diaphragm valves exporter, providing clients worldwide with high-quality, tested, and proven valve systems. Each valve is carefully manufactured to meet international standards for performance, durability, and safety in demanding conditions. From bromine handling plastic diaphragm valves to chlor alkali and sulphuric acid applications, MVS PVDF diaphragm valves offer the performance and reliability your process demands.

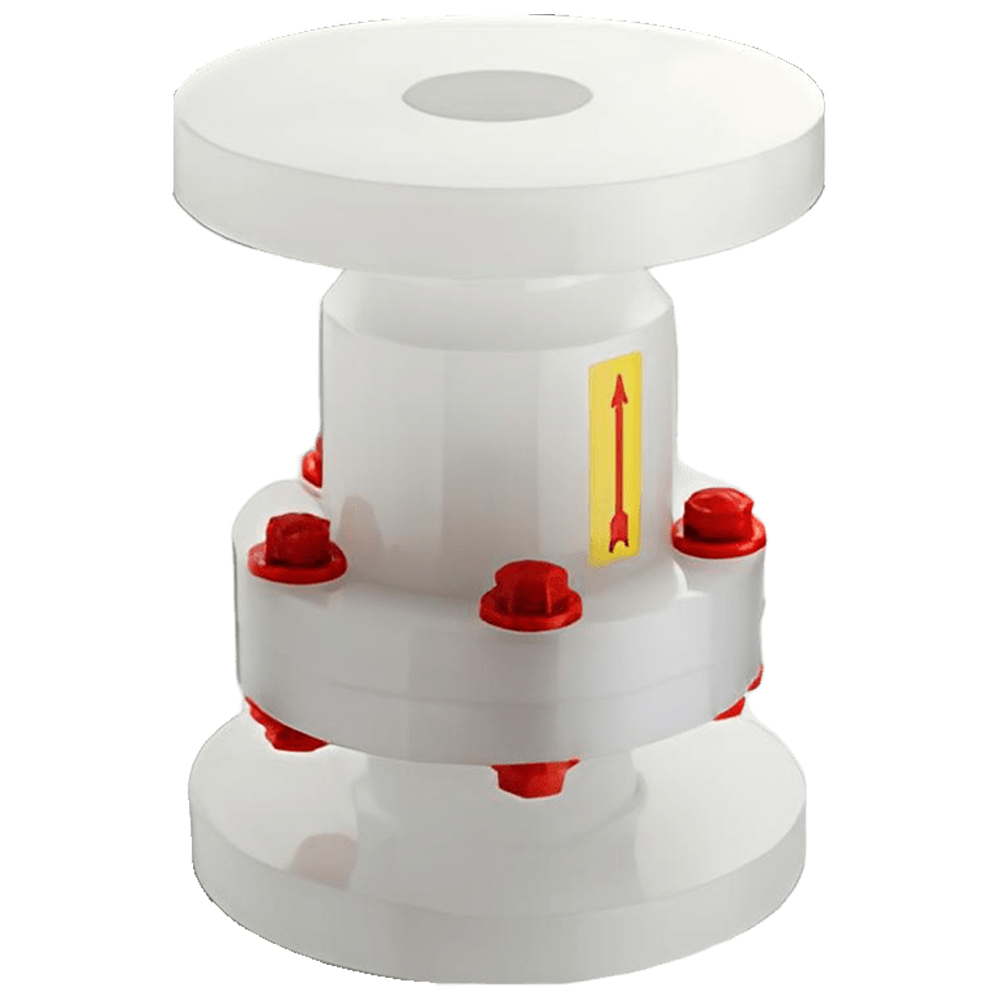

The MVS PVDF Ball Check Valve is a precision-engineered, non-return valve designed for use in highly corrosive and chemically aggressive environments. Built in a full bore two-piece construction, this valve operates on a simple yet effective ball-type check mechanism, ensuring unidirectional flow and preventing reverse flow in process pipelines. With options for flanged and screwed end connections, it offers maximum versatility for installation across a wide range of industrial applications. Constructed entirely from thermoplastic materials like Polypropylene (PP), PPH, and PVDF, this valve stands out for its exceptional resistance to corrosion, even when exposed to the most demanding media. The corrosion resistant thermoplastic ball check valve design ensures longevity, low maintenance, and dependable sealing performance, making it ideal for chemical handling industries. MVS is a reputed PPH ball check valve supplier and PVDF ball check valve exporter, serving a broad global clientele in sectors. Our polypropylene ball check valve and PVDF variants are specifically tailored to handle aggressive fluids such as sulphuric acid, nitric acid, and hydrochloric acid with complete safety and minimal wear. Designed for performance in challenging applications, these ball check valves for bromine and chlorine handling are also widely used in systems dealing with sodium hypochlorite, offering enhanced protection through their hydrochloric acid compatible design. Whether your operation involves continuous exposure to corrosive gases or harsh chemical liquids, the MVS PVDF Ball Check Valve offers a robust solution with zero compromise on durability or performance. By integrating chemical resistance, full-flow efficiency, and flexible connectivity, MVS delivers thermoplastic ball type check valves that set the benchmark in industrial non-return valve technology.

The MVS PVDF Foot Valve is an essential component for pump suction lines in aggressive chemical environments, combining the dual functionality of a ball check valve and strainer in a single robust unit. Designed in a two-piece full-flow body construction, this thermoplastic foot valve ensures uninterrupted suction performance while preventing backflow and debris entry, protecting pumps from damage and extending their service life. Constructed using high-performance materials such as PVDF, Polypropylene (PP), PPH, and HDPE, the valve guarantees corrosion resistance even in the harshest media. This corrosion resistant thermoplastic foot valve is engineered with soft-seated, ball-type sealing and optional ceramic/PTFE check balls to enhance chemical compatibility and sealing reliability. Widely used in chlor alkali plants, chemical process systems, and acid handling units, the PVDF foot valve for chemical industries is ideal for suction-side applications involving sulphuric acid, hydrochloric acid (HCL), and nitric acid. With pressure ratings of PN 10–16 (ANSI 150) and temperature resistance from –20 °C to +120 °C, this valve supports global standards such as DIN, ANSI, and JIS.

Recognized as a trusted acid resistant plastic foot valve manufacturer, MVS offers tailored solutions for industrial clients worldwide. As a leading PPH foot valve supplier and chlor alkali foot valve exporter, we ensure long-lasting, maintenance-friendly valves that perform reliably in high-demand operations.

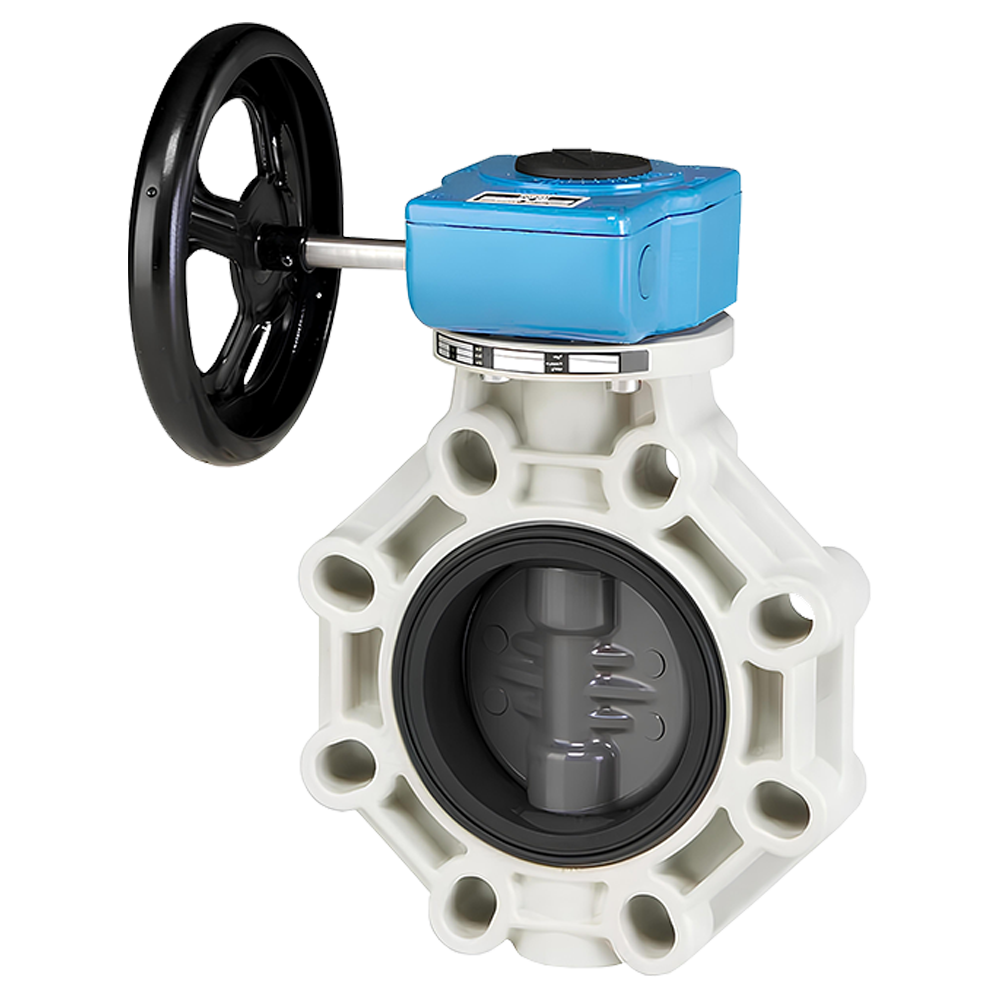

The MVS PVDF Butterfly Valve is engineered for demanding industrial applications that require safe and reliable flow control in highly corrosive and chemical environments. Designed in a compact wafer/sandwich style, this corrosion resistant PVDF butterfly valve fits seamlessly between ANSI B16.5 (150#) flanges, providing efficient sealing and optimal space utilization. With size options ranging from 50 mm to 300 mm, it offers flexible integration into diverse process systems. Manufactured using high-grade PVDF, PP, and PPH materials, the valve delivers exceptional resistance to harsh media such as hydrochloric acid (HCL), nitric acid, sodium hypochlorite, and chlorinated paraffin wax. This makes it a preferred choice across the chemical industry, wastewater treatment facilities, and processing units handling chlorine, acids, and other aggressive fluids. As a trusted PVDF butterfly valve manufacturer and PP butterfly valve supplier, MVS ensures that each valve is precision-engineered for consistent performance, long service life, and low maintenance. The acid resistant thermoplastic butterfly valve body design minimizes pressure drops while the thermoplastic disc and liner provide secure shut-off and enhanced media compatibility. For plants looking to safeguard their systems from chemical wear and fluid contamination, MVS offers advanced solutions like the PPH butterfly valve for chemical industry and the chlorine resistant PVDF butterfly valve. The valve is ideal for installations where durability and chemical resistance are non-negotiable, particularly in acid processing lines, industrial effluent systems, and chemical dosing systems. Whether you need a hydrochloric acid resistant butterfly valve or a sodium hypochlorite butterfly valve supplier, MVS stands as a reliable partner in providing robust, high-performance thermoplastic butterfly valves tailored for harsh and specialized applications.

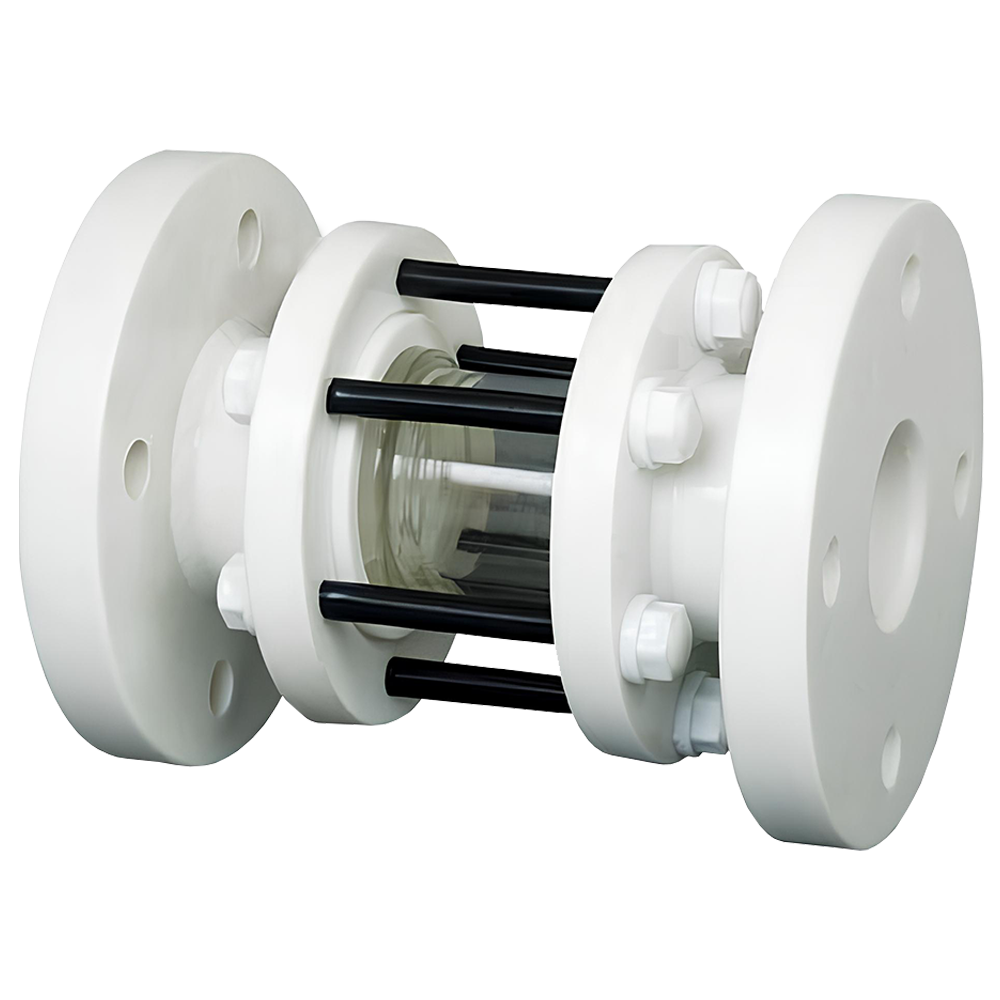

The MVS PVDF Sight Glass is a high-clarity visual inspection solution engineered for aggressive chemical environments. Designed with full PVDF housing and a durable borosilicate glass tube, this unit ensures 360° visibility for safe and continuous monitoring of fluid flow. With a three-piece sturdy construction, it provides a wide viewing area for operators to clearly observe flow conditions in corrosive pipelines, helping to prevent process interruptions or failures. This corrosion resistant thermoplastic sight glass is available in sizes ranging from DN 15 to DN 150 (½″ to 6″) and is compatible with ANSI and DIN flange standards, pressure rated up to PN 16 (~10 bar), and capable of withstanding temperatures between –20 °C and +120 °C. Whether it’s handling water, acids, bases, or ultra-pure chemicals, this chlorine resistant thermoplastic PVDF sight glass offers excellent chemical compatibility and mechanical strength under demanding conditions. The chemical resistant polypropylene sight flow indicator and PPH sight glass supplier options make MVS Sight Glass ideal for viewing media such as sulphuric acid, nitric acid, hydrochloric acid (HCL), and chlorine-based solutions. Its tubular construction ensures low pressure drop and is commonly used in chlor alkali systems, bromine handling lines, and sodium hypochlorite flow indicators.

Engineered for long service life and low maintenance, the PVDF sight flow indicator from MVS is built to meet global safety and quality standards. It enables safe visual control over flow and filling in process lines, ensuring reliable and clear operation even in the most chemically aggressive environments.

MVS Valve is a leading manufacturer of Rubber Lined Diaphragm Valves, we are manufactured in accordance with best quality standards and are specifically designed to offer reliable and efficient fluid control in the most demanding industrial environments. These valves are suitable for handling corrosive, abrasive, and viscous fluids across various process industries. Weir Type Rubber Lined Diaphragm Valves, are engineered to deliver exceptional durability and performance under harsh conditions. These valves are designed in compliance with international quality standards, making them a preferred choice for flow control in chemical, mining, wastewater, and other corrosive fluid environments. Our valves are available with various lining and diaphragm combinations to make sure that compatibility with aggressive chemicals and process conditions. Whether you need Weir butyl rubber lined diaphragm valves for chemical resistance, or weir soft natural rubber lined diaphragm valves for gentle fluid handling, we have tailored solutions for every industry requirement. MVS also offers options such as weir hard ebonite rubber lined diaphragm valves, weir neoprene rubber lined diaphragm valves, and weir epdm rubber lined diaphragm valves, which cater to specific media handling and temperature needs. For industries that demand enhanced chemical resistance, our weir hypalon rubber lined diaphragm valves provide a reliable choice. A long side lined versions, we manufacture weir unlined diaphragm valves, including weir unlined stainless steel diaphragm valves, weir unlined carbon steel diaphragm valves, and weir unlined ductile iron diaphragm valves to serve general-purpose flow control requirements. We also offer configurations built to international specifications such as weir din standard unlined diaphragm valves and weir din standard rubber lined diaphragm valves. With the versatility of material choices, lining options, and compliance with DIN and ANSI standards, our WEIR-type diaphragm valves are the preferred solution for industries like chemical processing, mining, water treatment, and power generation. Their compact structure, robust sealing mechanism, and long service life ensure optimal performance with minimal maintenance.

MVS Straight Through Diaphragm Valves are engineered for highly demanding fluid control applications where maximum flow, reliability, and ease of maintenance are essential. Designed with a full bore opening, this diaphragm valve makes sure unrestricted flow, making it highly effective in handling viscous slurries, corrosive chemicals, and abrasive fluids. This valve design helps industries meet precise piping requirements while making sure long-term operational performance. The internal structure of the Straight Through Diaphragm Valve allows the flowing media to avoid contact with moving mechanical components, which dramatically increases the valve's lifespan and minimizes maintenance needs. To match varying process demands, MVS manufactures Straight Type Rubber Lined Diaphragm Valves using premium-quality materials and rubber linings. Depending on the application, we offer solutions such as Straight Type Butyl Rubber Lined Diaphragm Valves for strong chemical resistance, and Straight Type Soft Natural Rubber Lined Diaphragm Valves, ideal for applications requiring flexibility and smooth media passage. For highly abrasive conditions, Straight Type Ebonite Rubber Lined Diaphragm Valves deliver superior performance and extended durability. Where oil-resistance and moderate chemical compatibility are required, industries rely on Straight Type Neoprene Rubber Lined Diaphragm Valves. For high-temperature fluids and steam service, Straight Type EPDM Rubber Lined Diaphragm Valves are a proven choice. In industries requiring unlined options, Straight Through Unlined Diaphragm Valves are also widely used, especially in clean media systems. Straight Type Unlined Stainless Steel Diaphragm Valves are popular in food-grade and pharmaceutical settings, while Straight Type Unlined Carbon Steel Diaphragm Valves and Straight Type Unlined Ductile Iron Diaphragm Valves cater to general-purpose and water treatment sectors. MVS also provides diaphragm valves conforming to global dimensional standards, including Straight Type DIN Standard Unlined Diaphragm Valves and Straight Type DIN Standard Rubber Lined Diaphragm Valves, making sure compatibility and easy installation across international projects. Whether your requirement is for a Rubber Lined Diaphragm Valve for corrosive fluids or a durable Straight Through Diaphragm Valve suitable for continuous heavy-duty use, MVS delivers industry-trusted performance with every valve.

MVS Valve offers a high-performance Threaded Screwed End Diaphragm Valve designed for reliable operation in general-purpose industrial applications. Manufactured in a Weir Type design, this diaphragm valve is built with precision to ensure dependable flow control where threaded connections are required. It features BSPP threaded ends, making it ideal for compact pipelines and low-pressure systems where space and simplicity matter. This valve is constructed using Ductile Iron GGG40 coated with durable black epoxy, ensuring enhanced corrosion resistance and longer service life. The handwheel-operated mechanism allows for smooth manual operation, and the valve includes a visible yellow position indicator for better user control. The flow is regulated using a flexible EPDM or Neoprene rubber diaphragm, which provides a secure shutoff and reduces the risk of leakage even in extended usage conditions. The Threaded Screwed End Diaphragm Valve uses a seatless internal design with a bolted bonnet, ensuring ease of maintenance and minimizing replacement downtime. It’s simple linear motion and dependable performance make it a preferred choice in industries that handle non-aggressive fluids, including utilities, water distribution, process systems, and general fluid transfer setups. At MVS Valve, we supply Weir Screwed End Cast Ductile Iron Diaphragm Valves, Weir Screwed End Stainless Steel Diaphragm Valves, and Weir Unlined Threaded End Diaphragm Valves, offering versatile material options based on the chemical nature of the media. Whether you need a diaphragm valve for a new installation or a replacement in an existing system, our screwed-end solutions are built to deliver consistent results with minimal upkeep.

MVS Valve offers highly reliable Spare Weir Type Diaphragms designed for consistent performance and extended service life across a wide range of industrial diaphragm valves. Our diaphragms are engineered for maximum durability and compatibility, ensuring smooth operation even in the most demanding flow control environments. These replacement spare rubber diaphragms weir type components are tested to withstand harsh operating conditions with minimal maintenance. At MVS, we understand the importance of quality replacement components. That’s why industries trust us for their replacement spare EPDM rubber diaphragms weir type and replacement spare nitrile rubber diaphragms weir type, making sure long-lasting elasticity and resistance to chemicals and heat. For general-purpose sealing, our replacement spare neoprene rubber diaphragms weir type and replacement spare butyl rubber diaphragms weir type are manufactured to exact tolerances. Our replacement spare natural rubber diaphragms weir type are ideal for water and mild chemical applications, while for aggressive fluid environments, we offer replacement spare Hypalon rubber diaphragms weir type and replacement spare Viton rubber diaphragms weir type, known for their excellent resistance to acids and solvents. For more critical operations requiring superior protection, MVS also manufactures PTFE-backed rubber diaphragms. These options include replacement spare PTFE backed by EPDM diaphragms weir type, PTFE backed by neoprene, butyl, and Viton, combining the chemical inertness of PTFE with the flexibility of rubber. This layered design offers the advantage of long-term sealing performance without compromising diaphragm flexibility.

MVS Valve, we understand that industrial performance relies heavily on the durability and consistency of internal valve components. That’s why we manufacture and supply Spare Straight Through Diaphragms that are specifically engineered to match the demanding conditions of various industries. These diaphragms are essential components for maintaining peak valve performance in abrasive, corrosive, or high-pressure applications. Our Spare Straight Through Diaphragms are available in multiple premium-quality elastomer materials to cater to diverse operational needs. These include Replacement Spare Natural Rubber Diaphragms Straight Type, Replacement Spare EPDM Rubber Diaphragms Straight Type, and Replacement Spare Neoprene Rubber Diaphragms Straight Type, all offering excellent flexibility and sealing integrity. Designed for use in Straight Through Diaphragm Valves, these diaphragms ensure reliable service, reduced maintenance downtime, and longer operating life. We also offer high-performance options such as Replacement Spare Butyl Rubber Diaphragms Straight Type and Replacement Spare Nitrile Rubber Diaphragms Straight Type, which are ideal for chemical and oil-handling environments. For highly aggressive media, our Replacement Spare Hypalon Rubber Diaphragms Straight Type provide exceptional chemical and weather resistance, ensuring durability even in the harshest service conditions. Each diaphragm is crafted with precision to fit perfectly into straight-through valve assemblies, enabling consistent performance without leakage or failure. With a focus on compatibility, safety, and performance, MVS diaphragms are a preferred choice across industries such as water treatment, chemical processing, pharmaceuticals, mining, and more. MVS provides cost-effective, high-quality diaphragm replacements that match or exceed original equipment specifications.

MVS Valves’ Stainless Steel Gate Valve is engineered to deliver high-integrity shut-off performance across a wide range of fluid control applications, including water, steam, oil, and chemical services. Manufactured as per ASME and API standards, including API 600 and API 603, these valves offer unmatched corrosion resistance and flow efficiency. Built using materials such as CF8, CF8M, 316 Stainless Steel, and duplex grades, they are available with bolted bonnet or pressure-seal configurations and feature rising stem (OS&Y) operation with flexible wedge or solid wedge designs. We offer advanced valve configurations like the API 603 Corrosion Resistant Stainless Steel Gate Valve and API 600 Stainless Steel Gate Valve Flanged Ends Class 300, providing a reliable sealing mechanism under varying temperature and pressure conditions. Our corrosion-resistant variants such as API 603 150# CF8M Stainless Steel OS&Y Gate Valve and API 603 Stainless Steel Corrosion-Resistant Gate Valves are ideal for aggressive environments and critical fluid isolation where chemical resistance is a priority. MVS also manufactures Super Duplex F53 F55 5A 6A Gate Valves Flanged Ends for extreme durability and pressure containment, while our ASTM A 351 GR. CN7M Alloy 20 Bolted Bonnet Rising Stem Gate Valves are widely used in corrosive chemical processes. Designed to withstand Class 150 to Class 600 pressure ratings, these valves are tested according to API 598 standards for leak-tight performance. For municipal and utility applications, we offer Ductile Iron Flanged Gate Valve Bronze Trim Class 150, Ductile Iron Flanged Gate Valve Stainless Steel Trim Class 150, and Ductile Iron Flanged Gate Valve Aluminium Bronze Trim Class 150, each optimized for long service life and resistance to scaling or wear. Our product range also covers API 600 Cast Carbon Steel Gate Valve Flanged Ends Class 150, ensuring a complete solution for both stainless and carbon steel system requirements.

Precision-engineered Flexible Wedge Outside Screw and Yoke Bolted Bonnet API 600 Gate Valves are part of our standard supply, designed for low-pressure drop and effective sealing in full open or closed positions. Whether it's a Cast Steel Gate Valve or a specialized duplex model like the API 600 Duplex Steel Gate Valve Flanged End Class 600, every valve is crafted with meticulous attention to quality and performance.