Industrial Valves Manufacturer & Exporter

MVS Valves Double Flanged Butterfly Valve is engineered for precise and low-torque flow control in a wide range of pipeline systems. Designed with a concentric disc and resilient seat configuration, this valve ensures reliable shut-off and seamless operation across water, oil, gas, and chemical applications. Built in accordance with API 609, BS 5155, and ASME standards, it supports working pressures up to 16 bar and offers dependable leak-tight performance in both intermittent and continuous operations. Available in DN 50 to DN 1200 sizes, the valve is suitable for industrial pipelines that demand compactness, strength, and versatility. The double-flanged body of this valve supports easier installation and strong mechanical strength, making sure that improved durability under fluctuating pressure conditions. MVS Valves manufactures its API 598 Double Flanged Butterfly Valve to meet rigorous performance and sealing expectations. Whether used in horizontal or vertical orientation, it delivers excellent performance without compromising flow dynamics or efficiency. To address various fluid characteristics, the valve is offered with integrally molded resilient liners and comes with a wide range of sealing materials that match industrial media requirements. Material selection is a key strength of MVS’s design approach. Options such as Stainless Steel Double Flanged Butterfly Valve, Carbon Steel Double Flanged Butterfly Valve, Duplex Double Flanged Butterfly Valve, Duplex Stainless Steel Double Flanged Butterfly Valve and Super Duplex Double Flanged Butterfly Valve are manufactured to meet corrosive and high-pressure system demands. Whether for municipal water lines or critical chemical processing pipelines, these valves offer exceptional resistance to wear and corrosion while maintaining stable, smooth control.

With flexible actuation compatibility — manual lever, gearbox, pneumatic actuator, or electric actuator — the valve can be integrated effortlessly into automated systems or manual flow lines. The resilient seat variants are tailored using materials like EPDM, Nitrile, Viton, Hypalon, and Silicone, enhancing the valve's chemical compatibility and lifecycle performance. This ensures the API 609 Double Flanged Butterfly Valve meets global industrial flow control expectations with consistent results across service conditions. Manufactured by MVS Valves with precision and expertise, the API 598 Double Flanged Butterfly Valve offers unmatched reliability, safety, and quality assurance, making it the preferred choice for modern industries that value performance and long-term durability.

MVS Valves Double Window Sight Glass is a precision-engineered viewing device designed to offer continuous and reliable visual monitoring of process media in critical pipeline systems. This flow indicator consists of two thick borosilicate glass panes mounted on opposite sides of a cast or fabricated body, ensuring enhanced visibility and added safety. The rugged construction makes it ideal for industrial applications where clear observation is required under high pressure and elevated temperature conditions. Whether inspecting the color, clarity, or movement of a fluid, this sight glass enables accurate, real-time process checks without interrupting operations.

Manufactured using top-grade materials such as Cast Carbon Steel Double Window Sight Glass and duplex stainless steel variants, this product is well-suited for corrosive and demanding environments. The integration of PTFE-sealed gaskets and optional PTFE-lined Double Window Sight Glass configurations makes it particularly effective for chemical, pharmaceutical, and steam service applications where non-contamination and chemical resistance are essential. With support for pressure ratings up to 20 bar and temperature limits of up to 200 °C, it performs with dependable clarity and durability. The double-pane design also offers a built-in safety feature—ensuring uninterrupted visual access even if one glass layer cracks. Whether specified as a Double-window flow sight glass or a Duplex Double Window Sight Glass, this component remains a trusted choice for operators requiring visual flow assurance in harsh or sensitive pipeline conditions.

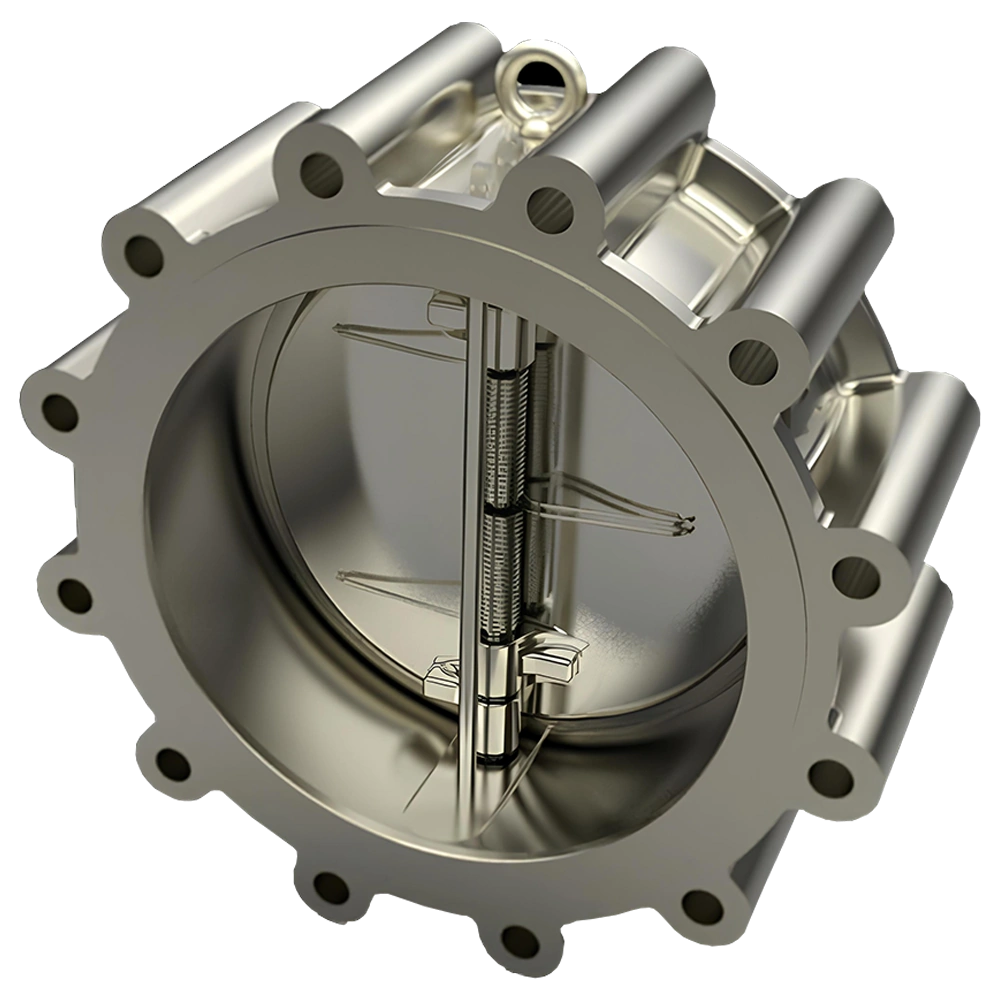

MVS Valves manufactures high-performance Dual Plate Check Valves engineered for reliability, efficiency, and space-saving design in various flow control systems. This type of valve is known for its lightweight construction, compact wafer body, and quick-closing functionality—making it the ideal solution for preventing backflow in both vertical and horizontal pipelines. Designed in compliance with API 594 and API 598 standards, the Dual Disc Check Valve features a spring-loaded twin-door mechanism that ensures silent, non-slam operation even under fluctuating flow conditions. Often referred to as a Double Disc Check Valve, Duo Wafer Check Valve, or Dual Flapper Check Valve, this versatile product is built to outperform conventional swing or lift check valves in strength, response speed, and space utilization. Our Dual Plate Check Valves are available in various materials to match your specific media and application needs, including Carbon Steel Wafer Body Dual Plate Check Valve Class 150, Stainless Steel Dual Disc Spring Loaded Wafer Check Valve CL 150, SS 304 CF8 Wafer Body Dual Plate Check Valve Class 150, and SS 316 Dual Disc Spring Loaded Wafer Check Valve CL 150. For aggressive or corrosive environments, MVS offers high-grade alloys like Duplex Steel Wafer Style Dual Plate Check Valve CL 150 and Super Duplex Wafer Type Dual Plate Check Valve Class 150, making sure longer life and consistent performance. Every Dual Disc Spring Loaded Wafer Check Valve features a retainerless body design to eliminate potential leak paths, while also allowing for installation between standard flanges without special adaptors. Whether it's a Wafer Pattern Twin Door Check Valve in cast steel or stainless steel, our product line supports seamless flow with minimal pressure drop and reduced maintenance downtime.

MVS also offers the Duo Wafer Check Valve Stainless Steel Carbon Steel variant, combining material flexibility with operational precision. From water treatment plants to petrochemical lines and high-pressure gas applications, these check valves provide efficient flow control without compromising safety or durability.

MVS Valves offers high-performance Swing Check Valves engineered to provide reliable and cost-effective backflow prevention across industrial, commercial, and municipal pipelines. These valves operate using a gravity or spring-assisted swinging disc mechanism that ensures unobstructed flow and closes promptly when reverse flow occurs, protecting systems from contamination and pressure surges. The design enables full-flow capacity with minimal pressure drop, making these valves highly efficient for continuous and intermittent operations. Built to meet international standards such as API 598, MSS-SP-71, and BS 1868, MVS Swing Check Valves are trusted for their durability and consistent performance under demanding pressure and temperature conditions. To meet a wide spectrum of industrial needs, MVS manufactures Carbon Steel Swing Check Valve Class 150 Flanged Ends, ideal for standard pipeline installations. For more demanding service conditions, the Stainless Steel Swing Check Valve Class 300 Flanged Ends and SS 304 CF8 Swing Check Valve Class 600 Flanged Ends provide enhanced corrosion resistance and long service life. In high-pressure environments, options such as SS 316 CF8M Swing Check Valve Class 900 Flanged Ends and Duplex Steel Swing Check Valve Class 1500 Flanged Ends offer superior mechanical strength and chemical resistance. For aggressive or marine applications where enhanced durability is critical, MVS also offers the Super Duplex Bolted Cover Swing Check Valve Flanged Ends, ensuring maximum operational security in highly corrosive environments. Additionally, for compact piping systems, the Stainless Steel Swing Check Valve Threaded Screwed Ends provides a flexible and space-saving solution, retaining the same reliability and sealing integrity. Available in both horizontal and Y-pattern cast configurations, MVS Swing Check Valves are constructed using materials like carbon steel, ductile iron, and high-grade stainless steels to suit a wide range of fluid media. These valves are easy to install, maintain, and operate—making them a preferred choice in sectors such as oil and gas, water treatment, chemical processing, and power generation.

Whether used in standard utility lines or more critical systems requiring high-pressure containment, MVS Swing Check Valves make sure dependable one-way flow and safeguard pipelines from reverse fluid movement while maintaining peak performance and minimal maintenance requirements.

MVS Valves offers robust and compact Wafer Check Valves designed to deliver reliable backflow prevention in various process, water, and industrial pipeline systems. The single plate wafer type check valve features a wafer style single disc swing type design that fits between flanges in a space-saving sandwich configuration. Conforming to API 6D and ASME B16.10 face-to-face standards, these valves are perfectly suited for pump discharge duties and applications requiring efficient shut-off performance with minimal pressure loss. The design incorporates an eccentric-mounted hinge pin and a precision-engineered disc seat that ensures positive sealing of the returning media. Offered in Swing short wafer carbon steel check valve and Swing short wafer stainless steel check valve variants, the Wafer Check Valve provides exceptional durability under varying pressure and flow conditions. For demanding applications, the SS 316 single door wafer check valve offers added resistance to corrosion, while the carbon steel wafer body thin type single plate wafer check valve is ideal for high-strength and budget-friendly installations. For operations that require enhanced responsiveness, MVS also manufactures Wafer Check Valves with a spring-loaded mechanism on request. This feature allows for quicker closing action and helps prevent water hammer, making them suitable for vertical and horizontal pipeline orientations. Whether it’s the Wafer Swing Check Valve, Stainless Steel Wafer Body Thin Type Single Plate Wafer Check Valve, or Wafer Style Single Disc Short Pattern API 6D Check Valve, each model guarantees reliable flow control in a compact footprint.

The combination of advanced manufacturing, high-grade materials such as carbon steel and stainless steel, and compliance with international standards like ASME, BS, and DIN makes MVS’s Single Disc Wafer Check Valves a trusted solution across critical industries. Their simple yet rugged construction ensures long service life, ease of installation, and consistent sealing performance, making them the go-to choice for efficient non-return flow management.

MVS Valves manufactures robust Forged Steel Check Valves designed to deliver consistent, one-directional flow in high-pressure gas, oil, and water pipeline systems. These valves are engineered with heavy-duty forged steel construction using premium materials such as ASTM A105, F304L, F316L, and special alloys including Inconel, Monel, and Alloy 20. Offering superior strength, compact body profiles, and leak-tight shutoff, our check valves are an ideal solution for demanding flow control environments across industries. Every Forged Steel Piston Lift Check Valve is crafted to meet rigorous international standards such as API 602, ASME B16.34, and BS 5352, making sure long-term performance and corrosion resistance under elevated temperatures and pressures. Available in various configurations such as Threaded, Socket Weld, Butt Weld, and Flanged Ends, these valves cater to Class ratings ranging from 150 to 2500. MVS also supplies API 602 A105 LF2 Forged Carbon Steel Check Valve Class 800 Socket Weld Ends, perfectly suited for high-pressure applications in refineries and chemical processing systems. Our horizontal piston type forged steel check valve incorporates a bolted cover design that guarantees mechanical integrity during sudden pressure surges. We also offer Forged Non Return Valve options with Lift or Piston-Lift mechanisms, including Forged Steel Piston Lift Check Valve Rating Class 800 Threaded/Socket Weld Ends and Forged Steel Piston Lift Check Valve Rating Class 1500 Threaded/Socket Weld Ends, each providing reliable non-slam flow control with minimal maintenance. MVS’s product lineup includes highly corrosion-resistant variants such as API 602 F304L Forged Stainless Steel Check Valve Class 800 Threaded Ends and API 602 F316L Forged Stainless Steel Check Valve Class 800 Butt Weld Ends, which are widely used in power plants and marine applications. Additionally, the company produces high-performance API 602 F5 F9 F11 F22 F91 Forged Alloy Steel Check Valves Class 800 Screwed Ends, which ensure chemical resistance and thermal stability. For critical flow lines, MVS supplies precision-built API 602 F51 Forged Duplex Steel Check Valve Class 150 Flanged Ends, API 602 F53 Forged Duplex Steel Check Valve Class 300 Flanged Ends, and API 602 F55 Forged Duplex Steel Check Valve Class 600 Flanged Ends, offering unmatched mechanical strength and excellent crack resistance. In aggressive environments, users rely on API 602 Inconel 625 Forged Check Valves Class 1500 Flanged Ends and API 602 Monel K400 Forged Check Valve Class 2500 Flanged Ends for extreme temperature and pressure control.

Whether it's a Forged Steel Piston Lift Check Valve Rating Class 150/300/600 Flanged Ends or a Forged Non Return Valve customized for your flow system, MVS ensures precision machining, zero leakage, and easy maintenance, making these valves a durable and high-performance choice for continuous operation in critical applications.

MVS Valves’ Forged Steel Gate Valve is engineered to deliver exceptional shut-off performance in high-pressure applications across industries like oil and gas, petrochemical, and power generation. Designed to API 602 and ASME B16.34 standards, this valve ensures tight sealing and smooth flow control in critical service conditions. Manufactured from premium grades such as ASTM A105, A105N, and stainless or alloy steels, it offers long-lasting reliability under extreme pressure and temperature fluctuations. With a choice of OS&Y or non-rising stem configurations, our API 602 Forged Steel Gate Valves are available with bolted or welded bonnet options, rising stems, and high-quality graphite or PTFE packing. Whether you're looking for an A105 Forged Steel API 602 Gate Valve Flanged Ends Class 150, or a F304L Forged Stainless Steel API 602 Gate Valve Flanged Ends Class 300, we offer complete flexibility in material and connection types to meet your precise operational needs. For environments that demand corrosion resistance and durability, MVS provides F316L Forged Stainless Steel API 602 Gate Valve Flanged Ends Class 600, along with high-performance alloy steel variants like F11, F22, F5, F9, and F91, suitable for various ends such as socket weld, butt weld, or threaded.

For more demanding conditions, we also manufacture LF2 Forged Carbon Steel API 602 Gate Valve Butt Weld Ends Class 2500, and specialized options such as F51, F53, and F55 Duplex Steel Forged Gate Valves. If you're operating in aggressive media environments, our exotic alloy range includes Inconel Forged Steel Gate Valve, Monel K400 Forged Steel Gate Valve, and Alloy 20 Forged Steel Gate Valve, ensuring the highest corrosion resistance without compromising on strength. Every valve undergoes rigorous testing to comply with international standards and ensure flawless performance throughout its service life.

MVS Forged Steel Globe Valves are meticulously engineered for high-pressure flow regulation and isolation duties in critical service pipelines. Designed in accordance with API 602, API 600, ASME, and API 598 testing standards, these globe valves are ideal for applications where tight shut-off, durability, and safety are essential. Constructed from ASTM A105 forged carbon steel, stainless steel, and exotic alloy steels, these valves deliver exceptional strength and corrosion resistance across demanding industrial operations. With OS&Y rising stem design, bolted or welded bonnets, and options for full or standard port configurations, API 602 Forged Steel Globe Valves by MVS ensure precise control over media flow. Widely used in oil and gas, steam, chemical, and power generation sectors, these valves are capable of handling pressure classes ranging from 150 to 1500 with consistent performance. As a trusted globe valve manufacturer, we ensure each product meets the toughest international specifications and performance expectations. For facilities that require cast valve configurations, MVS also offers Cast Carbon Steel Globe Valve and Cast Stainless Steel Globe Valve designs built to API 600 standards. These globe valves with bolted bonnet designs are suitable for Class 150 and Class 300 operations and deliver robust sealing even in fluctuating thermal and pressure environments. In higher-class services, our Exotic Alloy Steel Globe Valves comply with API 600 and provide optimal endurance under corrosive and abrasive conditions, particularly in Class 600-rated pipelines.

MVS also caters to specialized applications that demand corrosion-resistant materials. Our API 603 Corrosion Resistant Globe Valves and Stainless Steel Corrosion-Resistant Globe Valves are manufactured to meet the unique needs of aggressive fluid media and stringent environmental compliance. These are complemented by API 623 Globe Valves, which serve both severe thermal cycling and high-pressure requirements while maintaining low emission levels and long lifecycle operations. By offering a complete line-up—from Cast Stainless Steel API 603 Globe Valves Bolted Bonnet Flanged Class 150 to Exotic Alloy Steel API 600 Globe Valves Bolted Bonnet Class 600—MVS provides flexibility, reliability, and safety across various sectors.

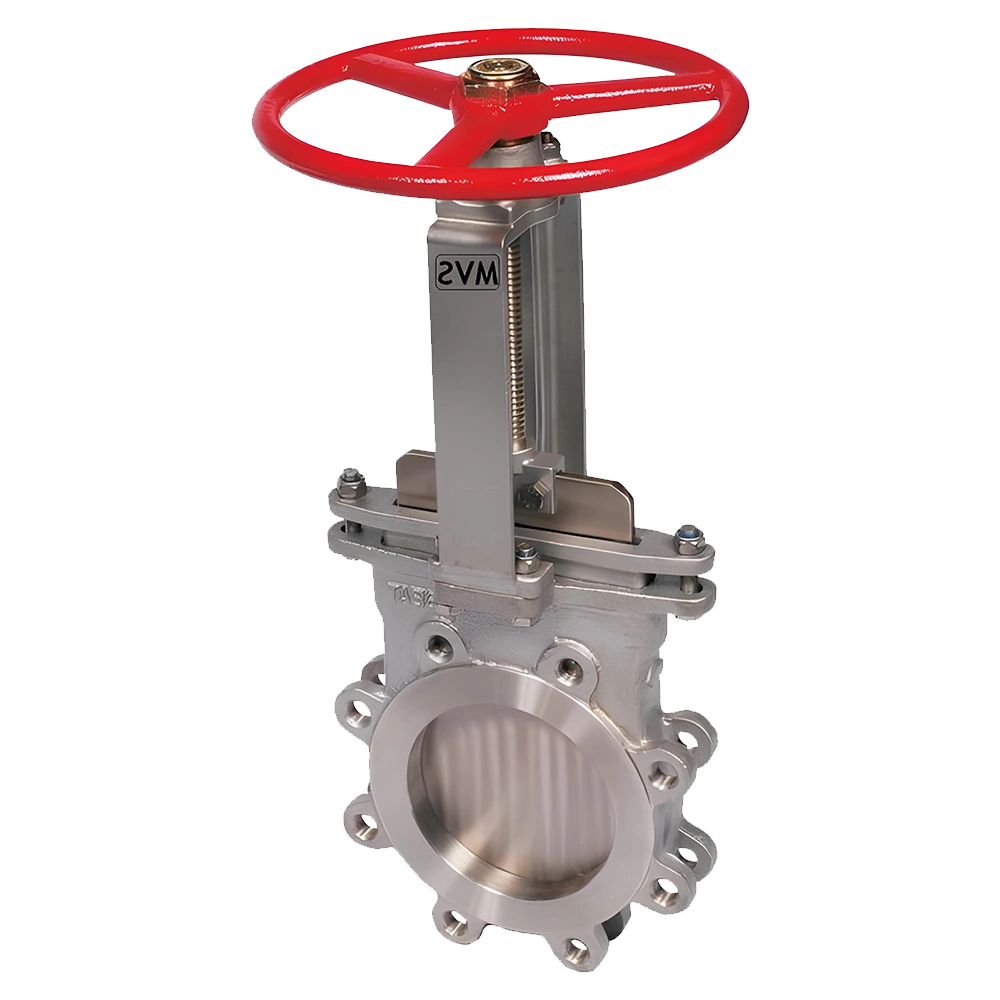

The Knife Gate Valve manufactured by MVS is a highly efficient flow control solution, engineered specifically for handling thick fluids, slurries, and solid-laden media across various industrial processes. Designed with precision, our stainless steel knife gate valves are available in both lugged and flanged end connections, ensuring flexibility in installation and secure, leak-proof performance. Covering a broad size range from 50 mm to 2500 mm and built to handle Class 150 pressure ratings, these valves offer dependable operation even under the most demanding conditions. MVS offers Knife Gate Valves in both unidirectional and bidirectional configurations, with seat options that include metal and resilient materials for optimal sealing. With a complete material selection, we manufacture carbon steel unidirectional knife gate valve semi lug type and carbon steel unidirectional knife gate valve full lug type for general applications, along with stainless steel unidirectional knife gate valve semi lug type and stainless steel unidirectional knife gate valve full lug type for environments requiring corrosion resistance. Higher-grade materials like SS 304 CF8 unidirectional knife gate valve semi lug type, SS 304 CF8 unidirectional knife gate valve full lug type, SS 316 CF8M unidirectional knife gate valve semi lug type, and SS 316 CF8M unidirectional knife gate valve full lug type offer additional protection in chemically aggressive and high-pressure environments. For even more demanding conditions, our lineup includes duplex steel unidirectional knife gate valve semi lug type and duplex steel unidirectional knife gate valve full lug type, as well as super duplex steel unidirectional knife gate valve semi lug type and super duplex steel unidirectional knife gate valve full lug type, delivering unmatched strength and durability. To serve a variety of utility and industrial sectors, MVS also manufactures cast ductile iron unidirectional knife gate valve semi lug type and cast ductile iron unidirectional knife gate valve full lug type, ideal for medium-pressure systems where mechanical integrity and cost-effectiveness must coexist.

At MVS, each Knife Gate Valve we deliver is more than just a component; it is a high-performance solution crafted with quality materials, engineered for rugged environments, and tested to meet exacting industrial standards. Whether for manual or automated operations, our valves ensure dependable shut-off and optimum flow control in every use.

MVS Valve offers a high-performance Lubricated Plug Valve engineered for reliable shut-off in critical industrial systems. Designed for use in petroleum refining, chemical processing, water treatment, and gas handling, our lubricated plug valves are built with a tapered plug mechanism that enables precise flow control and long-term sealing performance. With full metal-to-metal seating and a built-in lubrication system, the valve ensures smooth operation even under extreme pressure and temperature conditions. The internal design features a single moving component—the plug—which, along with a continuous lubricating film between the plug and the body, ensures minimal wear and prevents contamination. This configuration is highly effective in resisting corrosion and avoiding leakage, especially in processes involving slurries or corrosive media. Manufactured in compliance with API 6D, ISO, and BS standards, these valves meet international performance expectations and are available with flanged ends in a wide range of materials and pressure classes. we manufacture various options to meet demanding operational needs, including the API 6d industrial inverted high pressure balanced lubricated plug valve, suitable for heavy-duty applications. clients can also opt for high-grade variants such as the duplex API 6d industrial inverted high pressure balanced lubricated plug valve class 300 and nickel alloy API 6d industrial inverted high pressure balanced lubricated plug valve class 600, both engineered for enhanced corrosion resistance. for higher-pressure systems, we offer the stainless steel API 6d industrial inverted high pressure balanced lubricated plug valve 6d industrial inverted high pressure balanced lubricated plug valve class 1500, super duplex API 6d industrial inverted high pressure balanced lubricated plug valve 6d industrial inverted high pressure balanced lubricated plug valve class 2500, and carbon steel API 6d industrial inverted high pressure balanced lubricated plug valve 6d industrial inverted high pressure balanced lubricated plug valve class 900. Every valve is manufactured with precision machining and stringent quality checks to ensure zero leakage and consistent performance. Whether operated manually or fitted with actuators, our lubricated plug valves guarantee strength, reliability, and long service life, making them a smart choice for industries that cannot compromise on flow control integrity.

MVS offers high-performance Pneumatic Knife Gate Valves designed for applications that demand automated control with reliable shut-off in fluid and semi-solid handling systems. These valves are available in wafer, lugged, and flanged end connections, suitable for size ranges from 50 mm to 600 mm, with larger sizes available upon request. Built for Class 150 pressure ratings, these valves are engineered to perform in industries like wastewater treatment, pulp and paper, mining, and chemical processing where automation, durability, and sealing integrity are critical. Our Pneumatic Knife Gate Valve is manufactured with optional metal or resilient seat arrangements and is offered in both unidirectional and bidirectional configurations depending on system requirements. The valve's operation is powered primarily by a pneumatic cylinder in double-acting mode, with optional electric or hydraulic actuation based on the desired control method. Designed to operate efficiently in temperature conditions ranging from −29°C to 425°C, the valve delivers consistent performance across a broad spectrum of processing environments. At MVS, we manufacture a complete range of Cast ductile iron unidirectional pneumatic knife gate valve semi lug type and Cast ductile iron unidirectional pneumatic knife gate valve full lug type, ideal for general flow isolation tasks in corrosive and semi-solid media. For industries requiring greater corrosion resistance and longer service life, we offer Carbon steel unidirectional pneumatic knife gate valve semi lug type and Carbon steel unidirectional pneumatic knife gate valve full lug type, alongside Stainless steel unidirectional pneumatic knife gate valve semi lug type and stainless steel unidirectional pneumatic knife gate valve full lug type configurations. To meet more demanding process conditions, our material range includes ss 304 cf8 unidirectional pneumatic knife gate valve semi lug type, ss 316 cf8m unidirectional pneumatic knife gate valve full lug type, as well as duplex steel unidirectional pneumatic knife gate valve semi lug type and super duplex steel unidirectional pneumatic knife gate valve full lug type, making sure mechanical integrity under high pressure, aggressive chemicals, and extreme temperature applications.

Engineered as per international quality standards, MVS Pneumatic Knife Gate Valves offer smooth automation, minimal maintenance, and excellent sealing performance. With their rugged construction, reliable actuation, and extensive material availability, they are a preferred solution for clients looking for precision control and operational efficiency in challenging industrial setups.

MVS Valves is a trusted name in the manufacturing and export of PTFE Seated Butterfly Valve, delivering reliable sealing performance in highly corrosive flow applications. Engineered for precision control, these valves are widely preferred in chemical, pharmaceutical, and municipal water systems, where resistance to aggressive media and tight shut-off are essential. Our PTFE-seated butterfly valve design integrates a durable stainless steel disc stemmed through a resilient PTFE-lined seat, ensuring a long service life even under fluctuating pressure and temperature ranges. These valves are tested to API 598 and EN 12266 standards and designed as per API 609, making them suitable for demanding process conditions from –20 °C to +200 °C. Built for compatibility and ease of automation, the valves come with an ISO 5211 actuation mounting pad and are available in both wafer and lug-style body configurations. MVS manufactures concentric PTFE-seated butterfly valve options with replaceable seat design, providing easy maintenance and superior resistance to wear and corrosion. These valves are available in PN 10 pressure rating and are offered in cast iron, ductile iron, carbon steel, and stainless steel body materials, including CF8 and CF8M grades. Whether installed in vertical or horizontal lines, each carbon steel PTFE seated butterfly valve or ductile iron PTFE seated butterfly valve provides bubble-tight sealing performance in applications involving vacuum, steam, acids, or process fluids.

The MVS product range includes stainless steel PTFE seated butterfly valve variants that offer a perfect blend of mechanical strength and chemical stability, particularly beneficial in pharmaceutical and clean utility systems. Every PTFE seat is carefully selected and designed to provide excellent resistance to chemical attack, ensuring minimal torque, smooth operation, and long-term performance. Being a reputed API 609 PTFE seated butterfly valve manufacturer and exporter, MVS Valves delivers quality solutions with a focus on performance, durability, and global compliance, making our valves the first choice for industries that demand corrosion resistance without compromise.