Valves Manufacturer & Exporter

MVS Valve, our Single Piece Ball Valve is designed for precision, durability, and seamless performance in demanding industrial applications. Built as a two-way full port valve, it ensures unobstructed flow and minimal pressure loss—making it ideal for critical operations across sectors such as oil & gas, chemical processing, water treatment, and power generation. This valve is available in multiple material configurations including Carbon Steel, Stainless Steel, and Duplex Stainless Steel—each crafted to meet rigorous safety and quality standards. Whether you're using a Carbon Steel One Piece Ball Valve Full Port Flanged CL 150 - CL 300 or a Stainless Steel One Piece Ball Valve Full Port Flanged CL 150 - CL 300, you can expect superior resistance to corrosion, high structural strength, and reliable sealing even under harsh conditions. For improved safety, our Single Piece Ball Valve is manufactured with Fire Safe Design, offering protection during high-temperature exposure. The ISO 5211 actuator mounting base allows for seamless integration with automation systems using either Pneumatic or Electrical Actuators. These features are complemented by manual operation options such as lever or gear unit for flexible field control. Engineered to adapt, MVS also offers solutions like the Duplex SS One Piece Ball Valve Full Port Flanged CL 150 - CL 300, perfect for applications involving aggressive fluids or corrosive environments. Similarly, our Pneumatic One Piece Ball Valve Full Port Flanged CL 150 - CL 300 is widely used for automated processes where performance and responsiveness are critical. At MVS Valve, we don’t just manufacture valves—we deliver trust and efficiency with every unit. We provide the right solution to improve flow control and system safety.

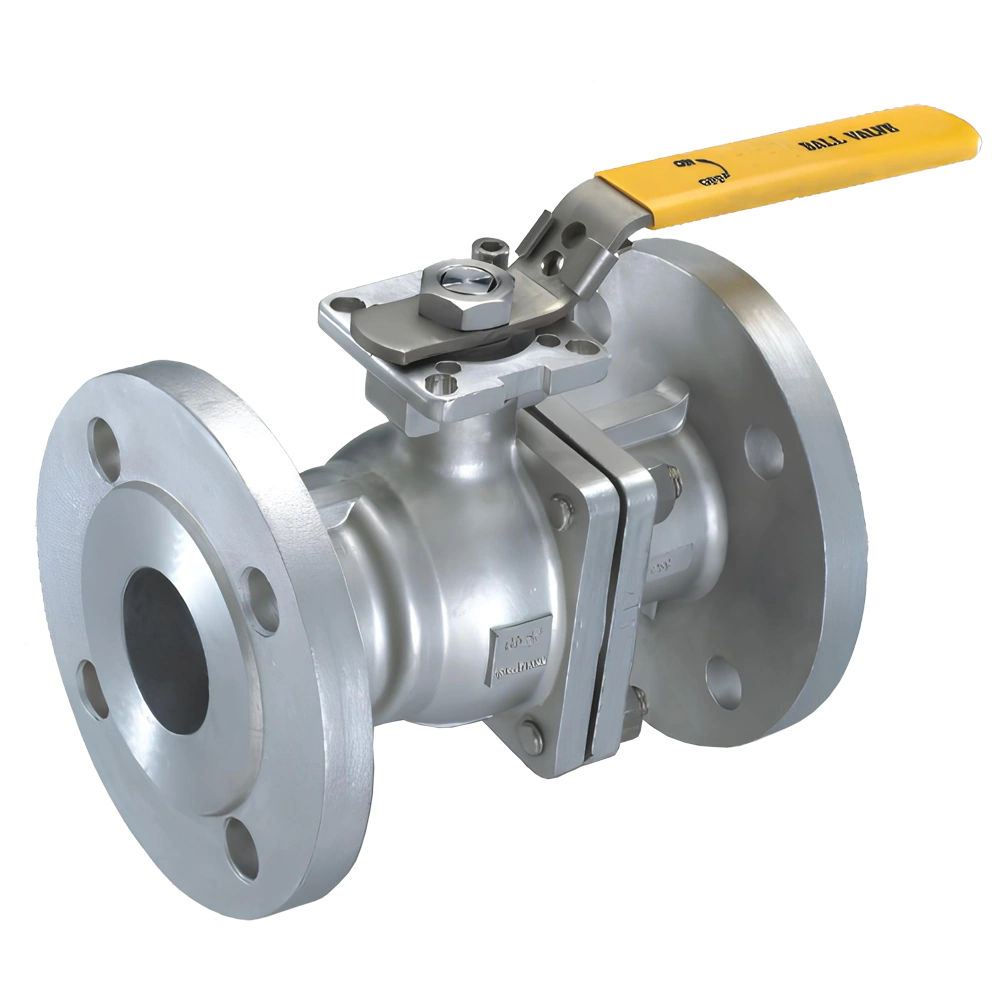

At MVS Valve, we specialize in manufacturing precision-engineered Two Piece Ball Valves designed for dependable shutoff and long-term performance in demanding industrial environments. Our Two Piece Floating Ball Valve, designed in compliance with API 608 standards, is ideal for industries such as oil and gas, chemical processing, water treatment, LPG, and propane systems. These valves are manufactured using high-quality Carbon Steel, Stainless Steel, and Duplex Stainless Steel, and are available with Full Port Flanged End Connections in CL 150 and CL 300 ratings, making sure compatibility with global pipeline requirements. The compact yet strong two-piece body design is available in both full and reduced bore options, giving engineers flexibility in flow management. Each Carbon Steel Two Piece Ball Valve Full Port Flanged CL 150 - CL 300 is crafted to provide a high flow rate, resistance to wear, and operational efficiency in high-pressure systems. Our Stainless Steel Two Piece Ball Valve Full Port Flanged CL 150 - CL 300 models offer excellent corrosion resistance and reliability, especially in harsh fluid applications. For highly corrosive and offshore uses, the Duplex SS Two Piece Ball Valve Full Port Flanged CL 150 - CL 300 is the preferred solution due to its enhanced mechanical properties and long service life. For automated systems, Pneumatic Two Piece Ball Valve Full Port Flanged CL 150 - CL 300 variants are available, offering rapid actuation and tight shutoff in mission-critical applications. We also offer models with ISO direct mount configurations, such as the SS ISO Mount Pad Fire Safe Two Piece Ball Valve Full Port Flanged CL 150 - CL 300, which come with fire-safe construction, anti-static devices, and blowout-proof stem designs to meet international safety standards. These features, along with a gland-type sealing arrangement and locking provisions on request, ensure reliable and secure valve operation under all working conditions. Whether used manually or with actuators, our Two Piece Ball Valves provide low torque operation, excellent sealing, and a longer smooth operational life. The valves are engineered not just for fluid control, but for peace of mind—backed by MVS Valve’s commitment to quality, safety, and industry-leading support.

MVS Valve brings you a high-performance Three Piece Ball Valve, engineered to offer precision flow control, long operational life, and simplified maintenance across industrial applications. Designed with a rugged three-piece body, this valve makes sure secure and leak-proof sealing under high-pressure conditions, making it a reliable choice for industries such as chemical processing, petrochemical plants, oil and gas installations, and power generation units. Each Three Piece Ball Valve is manufactured with strong construction materials such as Carbon Steel, Stainless Steel, and Duplex Stainless Steel, and is available with Full Port Flanged End Connections as per Cl 150 and Cl 300 standards. The Carbon Steel Three Piece Ball Valve Full Port Flanged CL 150 is ideal for high-temperature and high-pressure fluid systems requiring strength and durability. For corrosion resistance and hygienic processing, the Stainless Steel Three Piece Ball Valve Full Port Flanged CL 150 delivers consistent and safe shutoff, especially in food-grade and chemical applications. The Duplex SS Three Piece Ball Valve Full Port Flanged CL 150 offers superior resistance to chlorides and harsh environments, making it suitable for offshore and high-stress environments. Our Pneumatic Three Piece Ball Valve Full Port Flanged CL 150 variant provides the benefits of rapid actuation and consistent shutoff performance in automated industrial setups. For enhanced safety and control, we also offer the SS ISO Mount Pad Fire Safe 3 Piece Ball Valve Full Port Flanged CL 150 - CL 300, which includes ISO 5211 actuator mounting pads, anti-static devices, and a certified fire-safe design that meets international safety regulations. Key operational benefits include low torque requirements, quick response times, and a positive shut-off mechanism that ensures leak-free service. These valves feature gland type sealing arrangements for dependable sealing and can be provided with locking provisions for open/close positions upon request. Known for their longer smooth life and maintenance-friendly design, MVS Three Piece Ball Valves are a trusted choice where performance, safety, and longevity matter most. Whether it’s a manual or automated solution, our three-piece ball valves deliver exceptional reliability across a range of fluid types and working conditions. We make sure compatibility with your existing infrastructure, making installation and servicing easier and more efficient.

MVS Valve offers a high-performance Two Piece Ball Valve with Threaded Ends, engineered for efficient shutoff and dependable flow control in industrial applications requiring threaded or socket weld connections. Designed as per API 6D standards, this valve features a strong and durable two-piece full bore body, making sure minimal pressure drop and smooth flow characteristics. This valve is well-suited for use in oil and gas, chemical processing, water treatment, and general industrial services. Built to handle high pressure and temperature conditions, it includes a fire-safe design, anti-static features, and a blowout-proof stem for enhanced operational safety and reliability. The Stainless Steel Two Piece Full Port BSPT Threaded Ball Valve option is ideal for installations where British Standard Pipe Taper (BSPT) threading is required, providing tight sealing and resistance to leakage. For markets that require NPT threads, our Stainless Steel Two Piece Full Port NPT Threaded Ball Valves offer dependable performance with high mechanical strength and corrosion resistance. Additionally, MVS manufactures Stainless Steel Two Piece Full Port Socket Weld Ball Valves for high-pressure systems where secure, permanent welding is preferred over threaded connections. Each configuration is crafted with precision to ensure maximum flow efficiency, durability, and ease of operation. Our Two Piece Ball Valve Threaded Ends are suitable for both manual and automated actuation and can be customized with ISO mounting pads for actuator installation upon request.

MVS Valve offers premium-grade Three Piece Ball Valve Threaded Ends designed for efficient flow control and secure shutoff in demanding industrial applications. Built in compliance with international standards including API 6D, ASME B 16.34, BS EN ISO 17292, and BS EN 1983, these valves deliver exceptional performance, even under high-pressure and high-temperature conditions. Crafted with a three-piece full bore body, this valve design facilitates easy in-line maintenance and cleaning without removing the entire valve from the pipeline—making it a practical choice for systems that require regular servicing. The available sizes range from ½” to 4”, with a pressure rating of 150#, supporting various flow requirements. Manufactured in Carbon Steel and Stainless Steel, MVS’s threaded ball valve range includes configurations for both BSPT and NPT threaded connections. Our Carbon Steel Three Piece Full Port BSPT Threaded Ball Valve and Stainless Steel Three Piece Full Port BSPT Threaded Ball Valve provide reliable sealing in systems using British thread standards. For American standards, we offer Carbon Steel Three Piece Full Port NPT Threaded Ball Valve and Stainless Steel Three Piece Full Port NPT Threaded Ball Valve, which deliver excellent corrosion resistance and durability in challenging fluid environments. Each valve is equipped with fire-safe and anti-static features, ensuring operational integrity in hazardous settings. A blowout-proof stem and a secure sealing mechanism further reinforce system safety. Optional ISO mounting pads are also available for actuator installation, making them ideal for both manual and automated operations. Whether installed in chemical lines, oil & gas distribution, or water treatment systems, MVS Three Piece Ball Valve Threaded Ends offer an unmatched combination of flexibility, strength, and longevity.

MVS Valves offers a highly reliable and precision-engineered 3 Way Ball Valve designed to handle complex flow control and diversion tasks in modern industrial systems. This valve is available in both L Port and T Port configurations, making it ideal for directing flow in multiple pathways depending on process requirements. Whether you require flow mixing, splitting, or diverting, the MVS 3 Way Ball Valve delivers optimal performance with minimal pressure loss. Built to support flanged, screwed, and socket weld end connections, our 3 Way Ball Valve lineup is versatile and adaptable across a range of industries. The design is based on advanced floating ball valve technology and is offered in full bore options under ASME Class 150 and Class 300 pressure ratings. Engineered for durability and smooth operation, our Carbon Steel Multiport Full Port Three Way Flanged Ball Valve Class 150 model is specifically built to withstand challenging applications involving chemicals, solvents, and industrial fluids. For operations where hygiene, corrosion resistance, and mechanical strength are critical, our Stainless Steel Multiport Full Port Three Way Flanged Ball Valve Class 150 stands out as the preferred choice across sectors like food processing, pharmaceutical, and water treatment. For automated and remote-controlled installations, the Pneumatic Multiport Full Port Three Way Flanged Ball Valve Class 150 option allows integration with pneumatic actuators, offering faster and more reliable control over fluid direction. Additionally, all MVS 3 Way Ball Valves can be equipped with Fire Safe Design and ISO 5211 actuator mounting pads, giving you the flexibility to use them with manual levers, gear operators, electric actuators, or pneumatic systems depending on the application's automation level. With its strong multiport body, bubble-tight shutoff capabilities, and long operating life, the MVS 3 Way Ball Valve is ideal for use in oil and gas refineries, petrochemical plants, power generation facilities, and general fluid control applications. Every valve is tested and manufactured to international standards, making sure consistent quality and exceptional performance across a wide spectrum of industrial operations.

MVS Valves offers high-performance Trunnion Mounted Ball Valves that are designed to deliver superior sealing and reliable operation in high-pressure and large-diameter flow control systems. Built to comply with API 6D standards, these valves are available in both Full Port and Reduced Port designs with Flanged or Butt Weld end connections. The design incorporates key features such as an anti-blowout stem, fire-safe construction, and double block and bleed capability, ensuring optimal safety, minimal leakage, and operational integrity even under extreme pressure and temperature conditions. To meet the specific requirements of demanding industrial applications, MVS manufactures a wide range of configurations including Cast Steel Full Port Reduced Port Three Piece Trunnion Mounted Ball Valve Flanged Class 300, Class 600, Class 1500, and Class 2500. We also offer Cast Steel Full Port Reduced Port Two Piece Trunnion Mounted Ball Valve Flanged Class 300, Class 600, Class 1500, and Class 2500, tailored to handle various pipeline needs in industries such as oil & gas, petrochemicals, refineries, and power generation. These trunnion ball valves are engineered with precision to ensure low operating torque, smooth actuation, and long-term durability. They are compatible with manual operation, as well as pneumatic or electric actuators, offering flexible control solutions across different flow media. With robust construction and advanced sealing technology, the MVS Trunnion Ball Valve range provides dependable shutoff and extended service life, even in the most critical flow conditions.

MVS Valves manufactures precision-engineered Disc Check Valves that offer compact design, reliable performance, and effective backflow prevention in demanding industrial systems. Designed for easy installation between flanges, these wafer flangeless sandwich type disco check valves are ideal for applications handling water, steam, gases, and various process fluids. Built as a stainless steel disc check valve wafer pattern, they are engineered to suit both vertical and horizontal pipelines, including downward flow conditions. The design includes a spring-loaded disc mechanism that ensures quick closure upon flow reversal, minimizing pressure loss and eliminating the risk of system contamination. We offer configurations such as the Stainless Steel Spring Loaded Disc Check Valves and the SS 316 Spring Loaded Disc Check Valve Wafer Style, all constructed to deliver optimal performance under varying pressure and temperature conditions. Available in Stainless Steel SS 316 wafer type non-return valve disc check valve options, our valves are offered with either metal seat or soft seat sealing, giving you flexibility based on your media and application. The wafer type stainless steel body spring tensioned disc check valve with metal sealing is especially suited for high-temperature applications, while soft seat options provide enhanced sealing for sensitive fluids. MVS also provides DIN flange stainless steel disco check valves and ANSI flange stainless steel disco check valves, expanding compatibility across international pipeline standards. Every valve is tested as per API/ASME standards to ensure consistent quality, strength, and performance across all use cases.

For systems that require compact, low-maintenance, and dependable non-return solutions, our Stainless Steel Wafer Spring Assisted Disc Check Non-Return Valves, available in both metal and soft seat variants, provide long-term service with minimal wear. Whether it’s power plants, chemical lines, or fluid distribution systems, MVS Disc Check Valves ensure a secure and leak-proof experience without compromising on efficiency or reliability.

MVS Valves manufactures high-quality Forged Steel Ball Valves engineered for robust performance in high-pressure and high-temperature environments. Designed with a reliable three-piece construction, these valves ensure long-lasting durability and leak-tight shutoff even under the most demanding industrial conditions. Each forged steel three-piece ball valve is available in both full port and reduced port options with threaded (BSPT and NPT) and flanged end connections to suit a wide range of system requirements. The valves are built for Class 800 pressure ratings when using screwed or threaded ends, and are also offered in Class 150, Class 300, Class 600, Class 1500, and Class 2500 for flanged versions, providing high adaptability for diverse operational needs. MVS Forged Steel Ball Valves are also available in special alloys on request, making them ideal for aggressive media and demanding process conditions. Each unit is crafted from a quality forged body that ensures strong, heavy-duty construction capable of withstanding mechanical stress and corrosive environments. These valves are equipped with features such as low operating torque, positive shutoff, and no lubrication requirement, which contribute to their smooth, long operational life and reduce maintenance efforts over time. Whether used in critical flow lines, high-pressure steam systems, or oil and gas pipelines, MVS Forged Steel Ball Valves offer precise flow control and high operational safety. Popular configurations include forged steel three piece ball valve full port BSPT threaded Class 800, reduced port BSPT threaded Class 800, and forged steel three piece ball valve full port NPT threaded Class 800 and NPT threaded Class 800. In flanged designs, MVS provides options like forged steel reduced port three piece ball valve full port flanged end Class 150, Class 300, Class 600, Class 1500, and Class 2500, each carefully engineered to meet international standards and industrial performance expectations. Designed for flexibility, these valves can be operated manually through lever handles or automated with pneumatic or electric actuators, depending on system integration needs. Their design and performance characteristics make them a preferred choice for refineries, petrochemical plants, steam and condensate systems, power generation units, and other fluid handling sectors that demand precision and safety.

MVS Valves' High Performance Offset Disc Butterfly Valve is meticulously engineered to offer precise control, reliable shut-off, and extended operational life in critical flow applications. Designed with a double offset disc, this valve significantly reduces seat contact during operation, which minimizes wear and enhances long-term sealing performance. This advanced design makes it particularly suitable for high-pressure and high-temperature pipelines across various sectors, including oil & gas, chemical, and power industries. Our High Performance Butterfly Valve is available in different construction types such as Double Flanged Short Pattern, Wafer Butterfly Valve, and Lug Style Butterfly Valve, providing installation flexibility for both new systems and retrofit projects. Whether you're managing aggressive media, elevated temperatures, or fluctuating pressures, this valve offers exceptional resilience and adaptability. Offered with options like high-performance metal seated butterfly valve for extreme conditions or soft-seated PTFE versions for chemical compatibility, it serves a wide spectrum of industrial needs.

MVS makes sure every valve complies with international standards and offers options for manual, pneumatic, or electric actuation to meet specific operational demands. With robust fire-safe configurations and tight shut-off capabilities, this valve excels in both safety and efficiency. The double offset geometry not only delivers enhanced torque characteristics but also ensures smooth cycling, which is essential for automated operations.

MVS Valve’s Wafer Butterfly Valve delivers a sleek, space-saving solution for flow control in tight piping systems. These valves are precision-engineered to API 609 and BS 5155 standards, ensuring reliable performance through sturdy disc construction and smooth stem bearing operation. Adjusted to fit pipelines from DN50 to DN1200 wafer butterfly valve range, they offer consistent shut-off and exceptionally low operating torque, making them ideal for both manual and automated systems. Constructed with a wafer-style body, this valve is available with either resilient or PTFE-coated wafer butterfly valve seats, providing superior sealing and chemical resistance. For applications requiring higher purity or corrosive media handling, the stainless steel wafer butterfly valve variant ensures durability without compromising flow integrity. The PTFE lining further enhances chemical compatibility, reducing the risk of contamination in sensitive processes. The API 609 wafer type butterfly valve design accommodates pressures up to PN 16/10 bar and even full vacuum conditions, supporting demanding industrial, water, HVAC, and light chemical applications. Added flexibility comes through ISO 5211 actuation mounting, which allows for seamless integration with manual handles or automated actuators—making this one of the best wafer butterfly valves for process industry use cases.

From its compact wafer-body and rugged seat options to standardized actuation compatibility and compliance with international standards, the MVS Wafer Butterfly Valve is a dependable, high-performance product for industries seeking effective flow control in limited spaces.

MVS Valves Lug Style Butterfly Valve is engineered for high performance and reliability across diverse pipeline systems, ensuring uninterrupted flow control in industrial, commercial, and utility-grade applications. Designed in compliance with API 609 and MSS-SP-67 standards, this lug type butterfly valve features a durable cast-body with precision-threaded lugs, allowing secure installation and dead-end service without the need for downstream flanging. Its compact body fits seamlessly in tight piping layouts, while the centrally mounted disc guarantees optimal sealing with minimal torque. Available in a wide size range from DN 50 to DN 1200, the valve supports working pressures up to 150 psi and can be operated manually or automatically through lever, gearbox, pneumatic, or electric actuation methods. It is ideally suited for water distribution, HVAC systems, chemical processing, and low-pressure gas pipelines. What sets MVS apart is the integrally moulded body with exceptional seat retention and sealing integrity. Every Lug Style Butterfly Valve is manufactured with the industry’s most trusted materials including Carbon Steel, SG Iron, and Stainless Steel (CF8 and CF8M). These options provide excellent corrosion resistance, mechanical strength, and compatibility with aggressive media. For enhanced sealing reliability, the valve comes with a variety of resilient rubber liner seat options like Black Nitrile, EPDM, Viton, Hypalon, and Silicon, ensuring performance across a wide range of temperatures and fluids. In addition, the valve is equipped with a stainless steel pad per ISO 5211, allowing easy integration with standardized actuators and mounting systems. This makes it highly versatile for automated flow control operations in demanding industries. Whether it's in municipal water projects, thermal fluid systems, or light chemical applications, the lug type butterfly valve from MVS Valves is designed to deliver exceptional flow control, resistance to wear, and long-term durability.

MVS Valves is committed to delivering superior butterfly valve technology by combining expert engineering, precision manufacturing, and strict quality testing. Each valve is carefully checked for leak-tight performance and durability, ensuring that customers receive only the best in flow management solutions.